The machinery used in rubber processing is essential in turning raw rubber into useful products that are utilized in a variety of sectors, such as consumer goods, automotive, construction, and healthcare. Innovation, efficiency, and sustainability are being propelled by advances in rubber processing technology in response to the growing demand for high-quality rubber products.

The Development of Equipment for Rubber Processing

Rubber processing equipment has evolved significantly since the 19th century, when the first rubber vulcanizing method was developed. The quality of the products was uneven in the past due to the manual operation and lack of accuracy of the equipment. On the other hand, contemporary rubber processing gear delivers unmatched accuracy, consistency, and efficiency because to the introduction of automation, computerization, and sophisticated engineering processes.

Principal Types of Rubber Processing Equipment

1. Rubber Mixing Mills: These are devices that combine additives and raw rubber to get the required results. Automated controls are a characteristic of modern mixing mills that guarantee consistent mixing and minimize material waste.

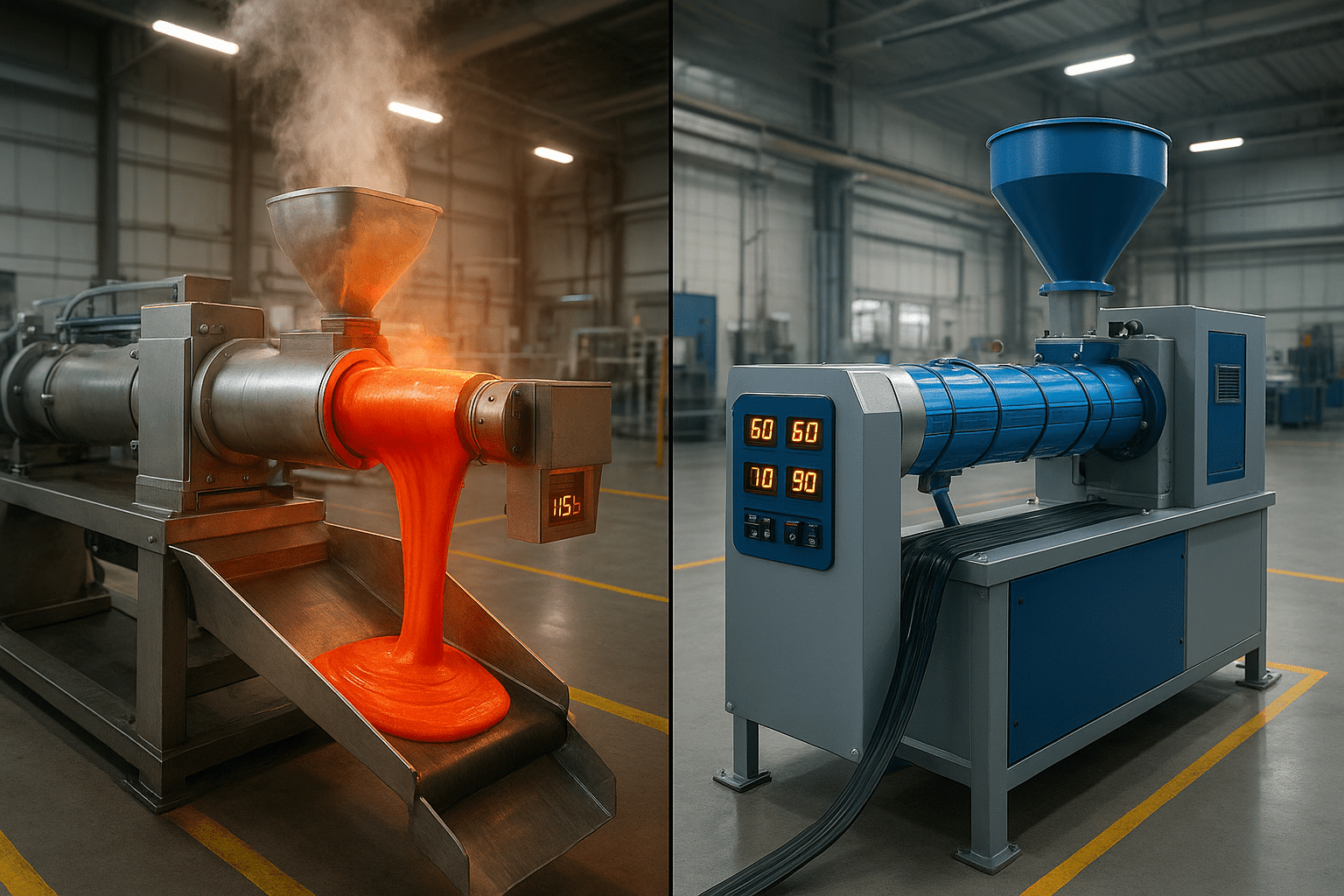

2. Rubber Extruders: Extruders play a crucial role in molding rubber into continuous profiles, including sheets, seals, and tubes. Precision temperature and pressure controls found in advanced extruders allow for the very accurate creation of intricate forms.

3. Rubber Vulcanization Presses: Rubber is vulcanized through a curing process that increases its suppleness and strength. The modern heating and cooling systems used by vulcanizing presses guarantee reliable curing and superior final products.

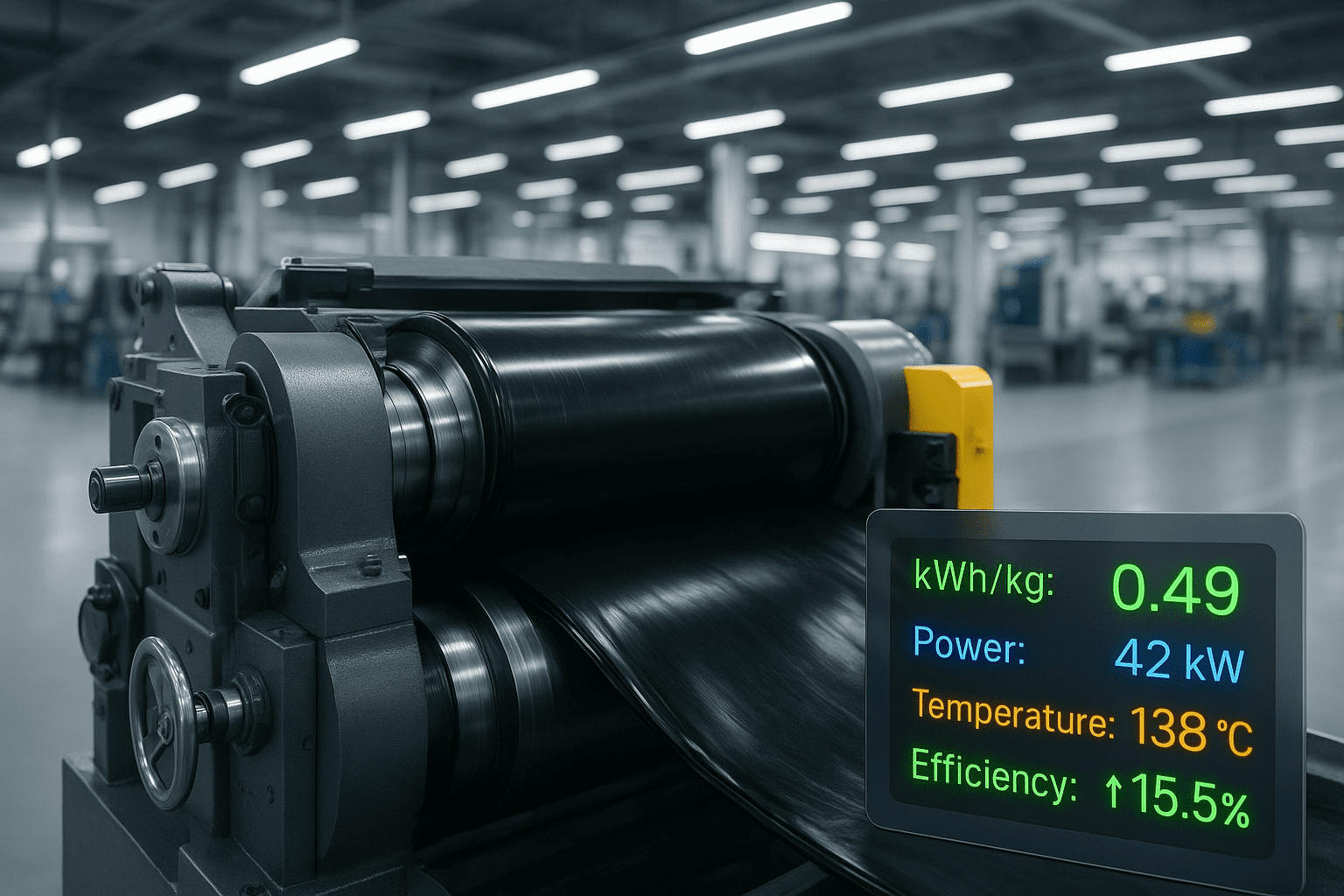

4. Calendering machines: To create thin sheets or coatings, rubber is passed through a succession of rollers during the calendering process. With the use of digital controls and sensors, modern calendering machines can precisely manage thickness and provide more consistent results.

Several major factors are driving innovation in rubber processing machinery:

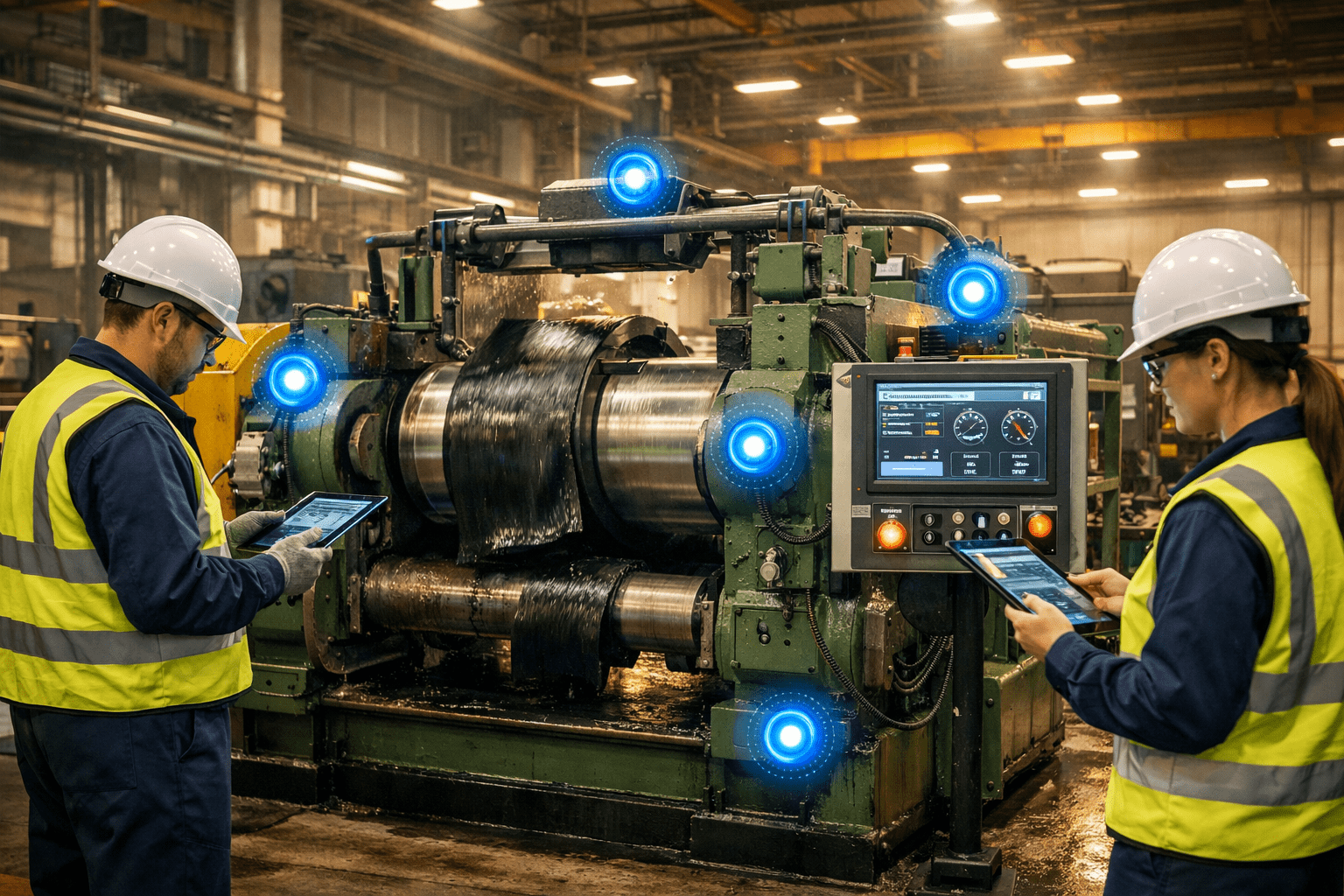

1. Automation and Digitalization: Automation guarantees constant product quality, speeds up manufacturing, and lowers human error. Real-time monitoring and predictive maintenance are made possible by digitalization, which also involves the use of AI (Artificial Intelligence) and IoT (Internet of Things), which reduce downtime and maximize efficiency.

2. Energy Efficiency: When manufacturing rubber, energy usage is a major consideration. Energy-efficient features like variable frequency motors, energy recovery systems, and improved insulation are all part of the design of modern machinery, which aims to minimize energy consumption and operating expenses.

3. Sustainability: In the industrial industry, environmental sustainability is becoming more and more significant. Manufacturers of rubber processing equipment are concentrating on creating environmentally friendly technology, such systems for recycling used rubber waste, lowering emissions, and utilizing additives that may be biodegraded.

4. Flexibility and Customization: The capacity to modify equipment to create distinctive forms, dimensions, and characteristics is essential as markets need for an increasing number of specialty rubber goods. Machines that are easily adjustable to various manufacturing needs are becoming standard.

5.The Value of Accuracy and Reliability: Precision and quality are crucial while treating rubber. Products that are inconsistent or defective can cause a company to suffer large losses and harm its reputation. The sophisticated sensors, controls, and feedback systems built into today’s rubber processing equipment guarantee that every product fulfills exacting quality requirements.

Conclusion

Rubber processing equipment has a promising future thanks to ongoing developments that promote sustainability, efficiency, and creativity. Modern machinery will become increasingly important for enterprises hoping to remain competitive as markets change and demand higher-quality rubber goods. At Vikas Industries, we’re dedicated to leading the way in these developments by offering our clients innovative solutions that support their success and promote excellence in the sector.

With a focus on quality and a willingness to adopt new technology, the rubber processing industry may anticipate more productivity, less environmental impact, and better product performance in the future.