Rubber processing machinery transforms raw rubber into finished products used worldwide. These specialized machines handle every step from mixing to final shaping. Understanding rubber processing equipment helps manufacturers choose the right tools for their business.

This guide covers what rubber processing machinery is, different machine types, and how to select equipment. You’ll learn about top manufacturers and find solutions for any production scale.

What is Rubber Processing Machinery?

Rubber processing machinery includes all equipment used to transform raw rubber materials into finished products. These machines handle mixing, shaping, curing, and finishing operations.

The rubber industry depends on these machines to create consistent products. From car tires to medical gloves, rubber processing equipment makes production possible.

Main Functions of Rubber Equipment

Rubber processing machines perform four key functions:

- Mixing: Combining rubber with additives and chemicals

- Shaping: Forming rubber into desired shapes and sizes

- Curing: Adding strength through heat and pressure treatment

- Finishing: Cutting, trimming, and preparing final products

Each function requires specific equipment types. Most facilities use multiple machines to complete the full process.

Why Proper Equipment Matters

Quality rubber processing machinery ensures consistent product standards. Poor equipment leads to defects, waste, and production delays.

Modern machines offer precise control over temperature, pressure, and timing. This precision creates better products and reduces material waste.

Types of Rubber Processing Machines

The rubber industry uses many different machine types. Each serves a specific purpose in manufacturing. Understanding these machines helps you plan production lines effectively.

Mixing Equipment for Rubber Compounds

Mixing machines combine raw rubber with various additives. Proper mixing creates uniform compounds with consistent properties.

Internal Mixers Internal mixers use rotating rotors inside closed chambers. They provide excellent temperature control and consistent results. Large facilities prefer internal mixers for high-volume production.

Two-Roll Mills Two-roll mills feature rotating cylinders that mix materials. Operators feed rubber between the rolls for processing. These mills work well for smaller batches and specialty compounds.

Dispersion Kneaders Dispersion kneaders excel at mixing difficult materials like carbon black. They use intensive kneading action to break down particle clusters.

Shaping and Forming Machines

Shaping machines give rubber its final form before curing. Different products require different forming methods.

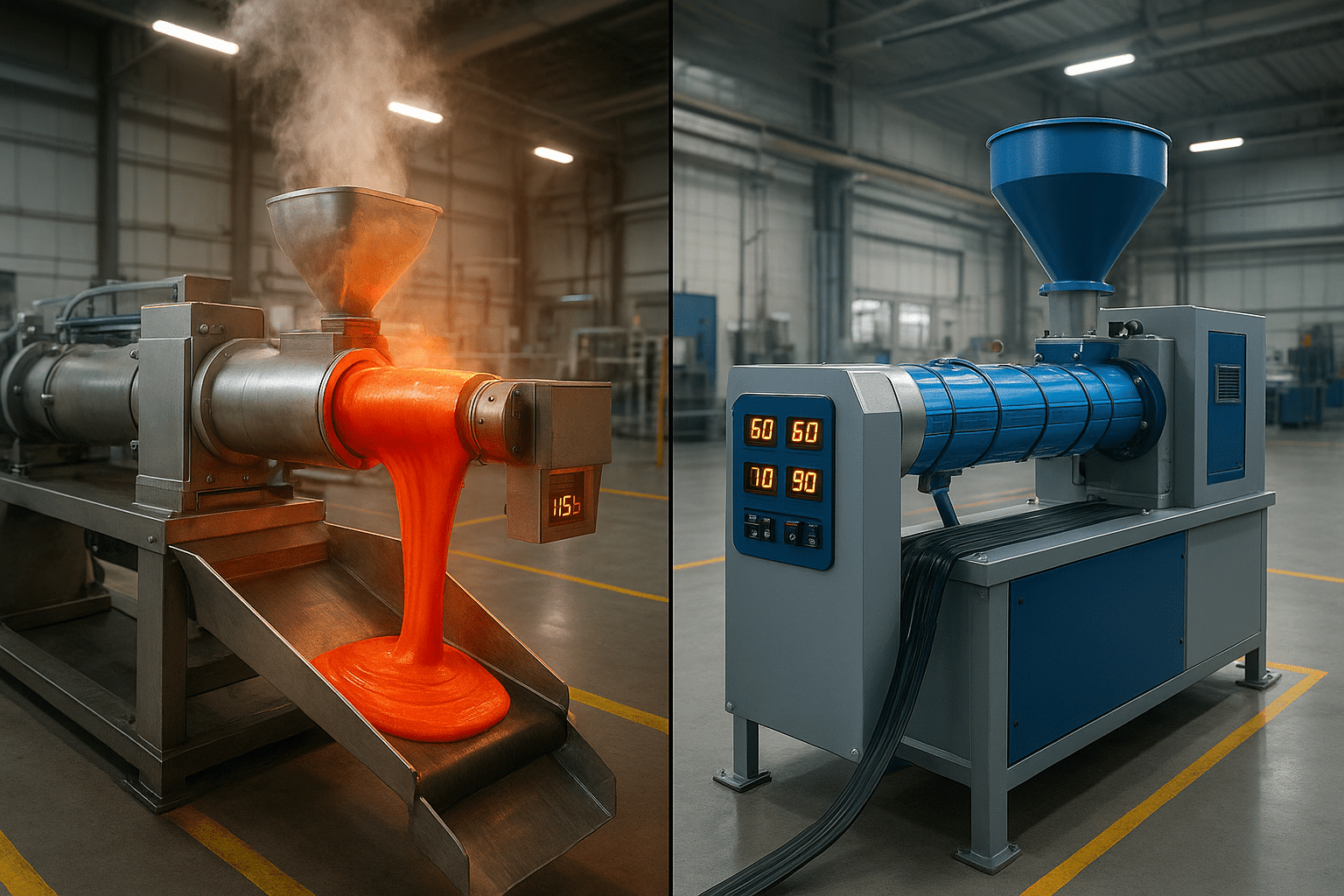

Rubber Extruders Extruders push heated rubber through shaped dies. They create continuous profiles like tubes, strips, and gaskets. Extruders handle high-volume production efficiently.

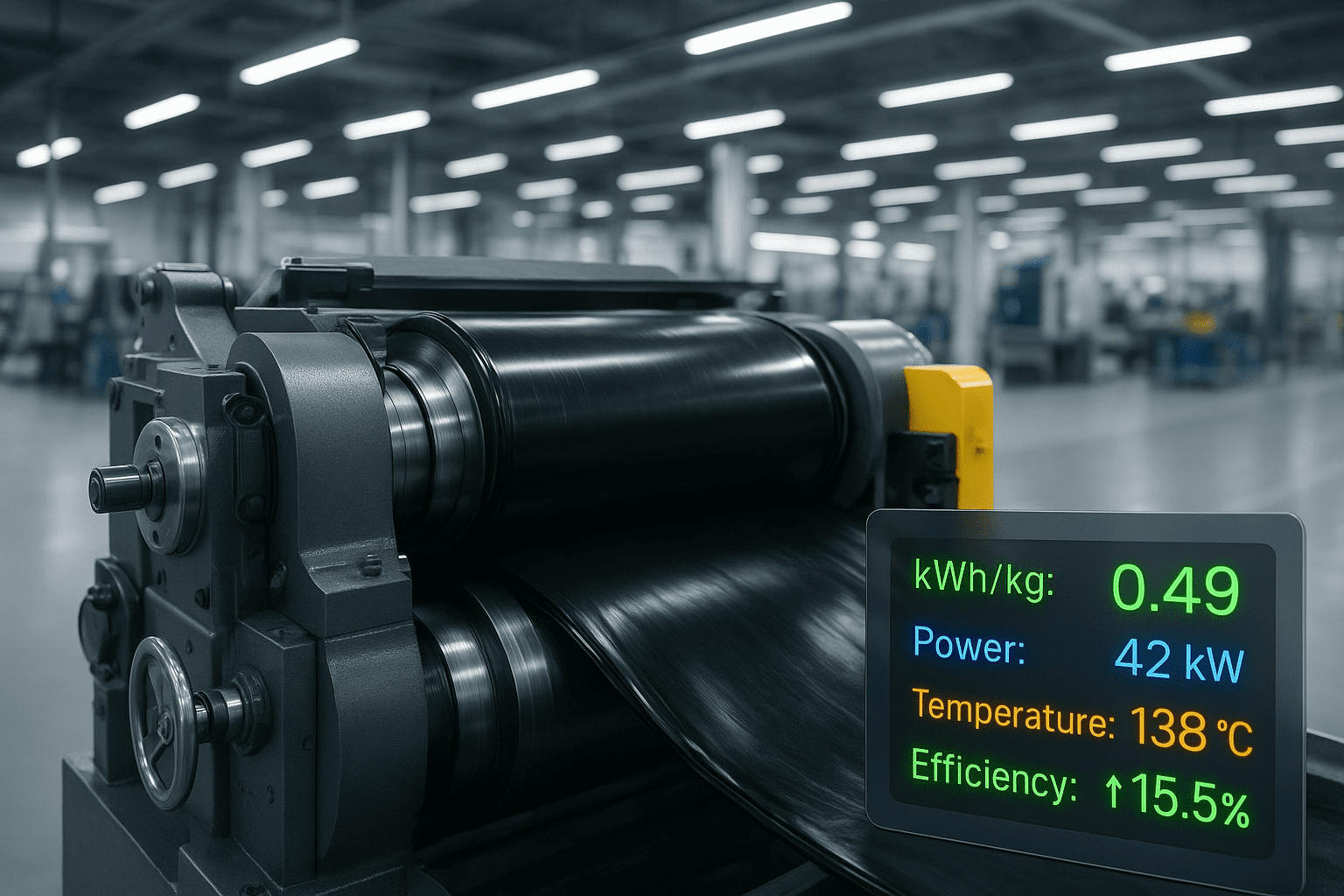

Calendering Equipment Calendering machines create thin rubber sheets. Multiple heated rolls compress rubber to precise thicknesses. The automotive industry uses calendered rubber extensively.

Compression Molding Presses These presses shape rubber using heat and pressure in molds. They produce complex parts with excellent surface finishes. Compression molding works well for thick products. Learn more about hydraulic presses and their versatile applications in vacuum and compression molding.

Injection Molding Systems Injection molding forces heated rubber into precision molds. This process creates detailed parts with minimal waste. Medical and electronic industries prefer injection molded components.

Curing Equipment for Vulcanization

Curing machines strengthen rubber through vulcanization. This process adds elasticity and durability to finished products.

Continuous Vulcanization Lines These systems cure rubber continuously as products move through heated chambers. They work perfectly for cables, hoses, and profiles.

Batch Autoclaves Autoclaves cure multiple products simultaneously using steam. They provide uniform heating for complex shapes and thick products.

Hot Air Ovens Hot air ovens cure rubber using circulated heated air. They offer precise temperature control for sensitive applications.

Finishing Equipment

Finishing machines prepare products for final use. They add surface treatments, cut to size, and perform quality checks.

Cutting Machines Automated cutters trim products to exact specifications. Computer controls ensure precision cutting with minimal waste.

Surface Treatment Equipment These machines apply coatings, textures, or other modifications to rubber surfaces.

Rubber Processing Machine Manufacturers in India

India produces world-class rubber machinery for global markets. Indian manufacturers combine advanced technology with competitive pricing.

Leading Indian Equipment Suppliers

Vikas Industries Vikas Industries stands as a leading rubber processing machinery manufacturer in India. They specialize in high-quality hydraulic presses, compression molding equipment, and advanced rubber processing solutions. Their commitment to innovation and customer satisfaction has established them as a trusted name in the industry.

HF Group HF Group ranks among India’s largest rubber machinery manufacturers. They produce complete processing lines for various industries. Their equipment serves customers in over 100 countries.

Bharaj Machineries Bharaj Machineries specializes in rubber processing equipment for over 40 years. They manufacture mixers, mills, and calendering machines. Quality focus has earned them strong industry reputation.

Santec Group Santec Group offers comprehensive rubber processing solutions. They design custom equipment for specific customer needs. Their engineering expertise covers all processing aspects.

Flodyne Controls Flodyne Controls manufactures precision rubber processing equipment. They specialize in advanced control systems and automation solutions.

Benefits of Indian Manufacturers

Indian rubber machinery suppliers offer several advantages:

- Cost-effective pricing: Competitive rates without quality compromise

- Customization ability: Tailored equipment for specific requirements

- Strong service support: Local networks and spare parts availability

- Modern technology: Advanced designs with global best practices

- Export experience: Proven international market track record

These manufacturers understand both domestic and global requirements. They combine traditional expertise with modern manufacturing methods.

Best Rubber Machinery for Small Scale Industries

Small-scale manufacturers need different equipment than large operations. The best rubber machinery for small businesses balances capability with affordability.

Essential Small-Scale Equipment

Compact Mixing Systems Small internal mixers handle batches from 5 to 30 liters. They provide professional mixing without requiring huge floor space.

Laboratory Mills Smaller two-roll mills perfect compounds and prepare samples. They cost less than production mills while delivering quality mixing.

Benchtop Presses Small compression presses create prototypes and small production runs. They use standard hydraulic systems with temperature controls.

Mini Extruders Compact extruders produce small quantities of profiles. They work well for specialty products and custom applications.

Selection Factors for Small Operations

Investment Requirements Small businesses must balance equipment capabilities with available capital. Choose machines offering the best return on investment. For detailed guidance, read our comprehensive guide on how to choose the right rubber processing machine for your business.

Space Limitations Limited floor space affects equipment choices. Select compact machines that fit facilities without compromising safety.

Power Needs Smaller facilities often have limited electrical capacity. Choose equipment working with existing power infrastructure.

Maintenance Simplicity Simple, reliable machines reduce downtime and costs. Avoid complex equipment requiring specialized technicians.

Equipment Packages for Different Budgets

Starter Package (Under $30,000)

- 10-liter internal mixer

- Laboratory two-roll mill

- Small compression press

- Basic testing equipment

Growth Package ($30,000-$80,000)

- 20-liter internal mixer

- Production mill

- Multi-station press

- Small extruder

Expansion Package ($80,000-$150,000)

- 40-liter internal mixer

- Calendar line

- Injection molding machine

- Curing system

Each package provides complete processing capabilities for different business sizes.

Industrial Rubber Processing Equipment Features

Modern industrial rubber processing equipment incorporates advanced technologies. Understanding these features helps select appropriate equipment.

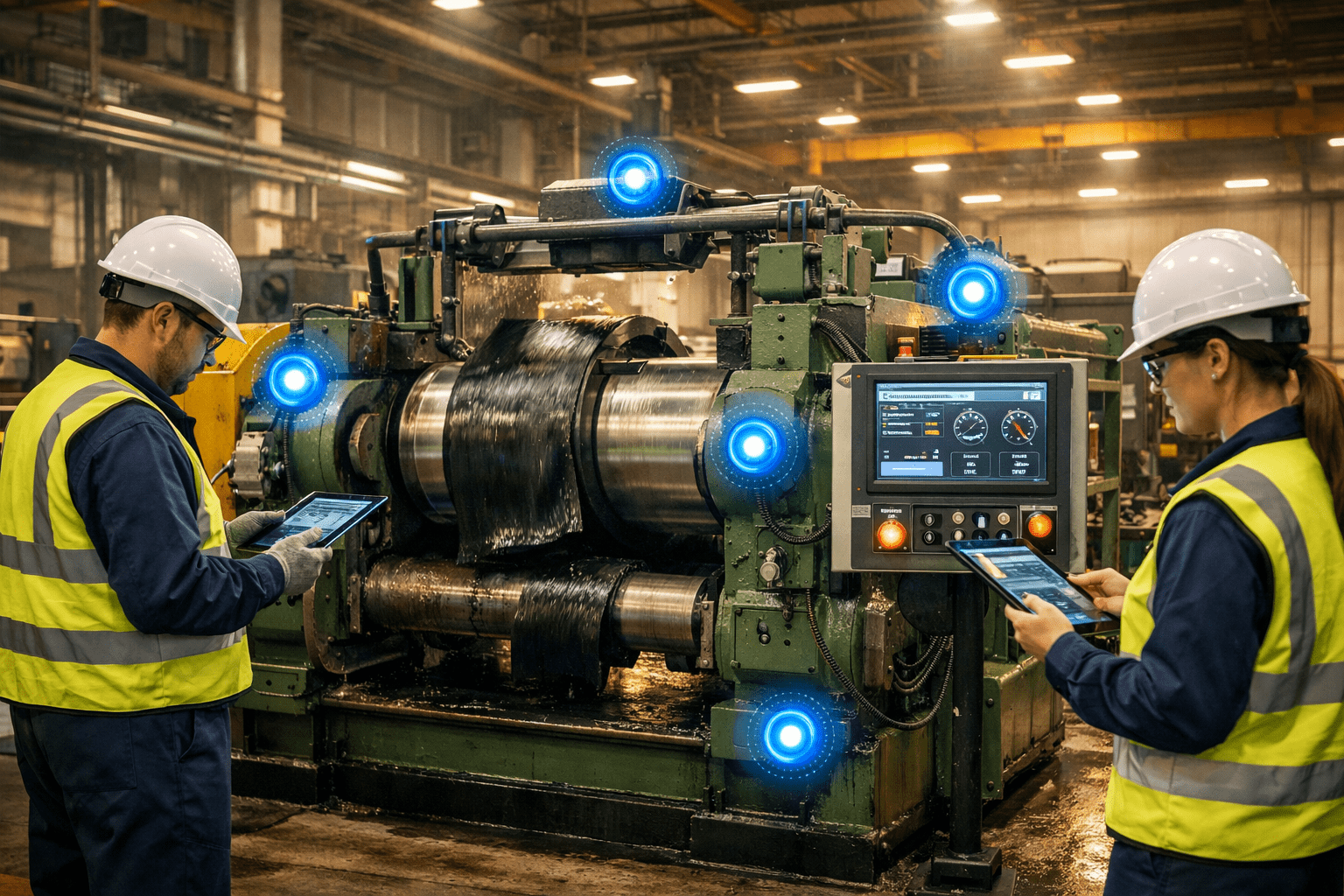

Automation and Control

Programmable Controllers Modern machines use PLCs for precise process control. These systems maintain consistent temperatures, pressures, and timing.

Touch Screen Interfaces User-friendly screens provide real-time process information. They simplify operation while reducing training needs.

Data Recording Advanced systems record production data for analysis. This information helps optimize processes and troubleshoot problems.

Safety Features

Emergency Systems All equipment includes comprehensive emergency stop capabilities. These protect operators and prevent damage during emergencies.

Safety Interlocks Interlocking systems prevent dangerous operations. They ensure proper sequencing and protect equipment.

Noise Reduction Modern equipment incorporates sound dampening materials. This creates safer, more comfortable work environments.

Energy Efficiency

Variable Speed Drives VFDs adjust motor speeds to match requirements. They reduce energy consumption while improving control.

Heat Recovery Advanced equipment captures and reuses waste heat. This significantly reduces overall energy costs.

Improved Insulation Better insulation minimizes heat loss and improves stability. This reduces energy consumption and improves quality.

Selecting the Right Equipment

Choosing appropriate rubber processing machinery requires careful consideration. The right equipment maximizes productivity while minimizing costs.

Production Analysis

Volume Requirements Calculate expected production volumes for different products. This determines capacity needs for each equipment type.

Product Specifications Different products require different processing capabilities. Complex products may need specialized features.

Quality Standards Industry requirements influence equipment selection. Medical and automotive applications demand higher precision.

Financial Planning

Budget Considerations Determine available investment capital. Consider financing options and cash flow impacts.

Operating Costs Calculate ongoing expenses including energy, maintenance, and labor. Lower initial costs may mean higher operating expenses.

Return Calculations Project equipment payback periods based on volumes and margins. Focus on equipment providing best long-term value.

Technical Requirements

Processing Capabilities Ensure equipment handles specific rubber compounds and requirements. Some machines work better with certain materials.

Automation Level Determine appropriate automation for your operation. Higher automation reduces labor but increases investment.

Integration Needs Consider how new equipment integrates with existing systems. Compatibility issues create expensive complications.

Maintenance Best Practices

Proper maintenance maximizes equipment life and productivity. Following best practices prevents costly breakdowns.

Daily Maintenance

Inspection Routines Operators should inspect equipment before starting production. This identifies potential problems early.

Cleaning Procedures Regular cleaning prevents contamination and buildup. Clean equipment produces better quality products.

Lubrication Checks Proper lubrication reduces wear and extends life. Use recommended lubricants at specified intervals.

Scheduled Maintenance

Preventive Programs Follow manufacturer maintenance schedules. Regular maintenance prevents major breakdowns.

Component Replacement Replace wear parts before failure occurs. This prevents unexpected downtime and damage.

System Calibration Regular calibration ensures accurate operation. Proper calibration maintains product quality.

Conclusion

Rubber processing machinery forms the foundation of successful rubber manufacturing. Understanding equipment types, manufacturers, and selection criteria helps make informed decisions.

Whether starting small or expanding operations, the right equipment combination determines success. Focus on machines matching production requirements while allowing future growth.

Indian manufacturers offer excellent equipment with competitive pricing and strong support. Their global experience ensures quality regardless of location.

Success requires more than good equipment. Proper maintenance, training, and improvement efforts maximize investment returns.

The rubber industry continues evolving with new technologies. Stay informed about trends to ensure equipment choices support long-term success.

Quality rubber processing machinery provides the foundation for profitable manufacturing. Evaluate options carefully and choose equipment serving business goals effectively.