If you’re still manually cutting rubber bales in your processing facility, you’re likely bleeding money, time, and safety—without even realizing it. The debate between investing in an automatic rubber bale cutter versus sticking with manual cutting methods isn’t just about convenience; it’s about your bottom line, worker safety, and operational efficiency.

In this comprehensive comparison, we’ll break down the real costs, safety risks, and speed differences between rubber bale cutters and manual cutting. Plus, we’ve included a downloadable spreadsheet template with actual numbers to help you calculate your potential ROI.

Understanding the Two Methods

Manual Rubber Cutting

Manual rubber bale cutting involves workers using handheld tools—typically industrial knives, guillotine cutters, or band saws—to slice through compressed rubber bales weighing anywhere from 33 to 35 kg. This labor-intensive process has been the traditional method for decades, but it comes with hidden costs that many manufacturers overlook.

Automatic Rubber Bale Cutters

Modern rubber bale cutters use hydraulic pressure to slice through rubber bales quickly, uniformly, and safely. These machines can cut bales into predetermined sizes with minimal human intervention, transforming what used to be a dangerous, time-consuming task into a streamlined operation.

Cost Comparison: The Real Numbers

Initial Investment

Manual Cutting Setup:

- Industrial cutting knives: $200–$500

- Safety equipment per worker: $150–$300

- Workbench/cutting station: $500–$1,000

- Total initial cost: $850–$1,800

Automatic Bale Cutter:

- Quality hydraulic bale cutter: $8,000–$25,000 (depending on capacity and features)

- Installation: $500–$1,500

- Total initial cost: $8,500–$26,500

At first glance, manual cutting seems significantly cheaper. But this is where most decision-makers make their critical mistake—they stop at the purchase price.

Ongoing Operational Costs (Annual)

Manual Cutting:

- Labor costs (2 workers @ 2 hours/day): $18,000–$30,000/year

- Blade replacements and tool maintenance: $600–$1,200/year

- Lost productivity due to inconsistent cuts: $3,000–$5,000/year

- Worker injury/insurance claims (average): $2,000–$8,000/year

- Total annual cost: $23,600–$44,200

Automatic Bale Cutter:

- Operator labor (0.5 hours/day): $3,000–$5,000/year

- Maintenance and hydraulic fluid: $800–$1,500/year

- Electricity: $300–$600/year

- Blade replacements: $400–$800/year

- Total annual cost: $4,500–$7,900

ROI Calculation: When Does the Investment Pay Off?

Let’s use mid-range figures for a realistic scenario:

Annual savings with automatic bale cutter: $33,900 (manual) – $6,200 (automatic) = $27,700 saved per year

Payback period: $17,000 (equipment cost) ÷ $27,700 (annual savings) = 7.4 months

Most facilities that switch to automatic bale cutters see a complete return on investment in less than one year. After that, it’s pure savings—year after year.

Safety Comparison: The Hidden Cost of Injuries

Manual Cutting Risks

According to the Occupational Safety and Health Administration (OSHA), cutting and slicing injuries are among the most common workplace accidents in manufacturing facilities. Manual rubber bale cutting specifically presents these hazards:

- Lacerations and Deep Cuts: Rubber bales are under extreme compression. When cut manually, they can spring back unpredictably, causing blades to slip and injure workers.

- Repetitive Strain Injuries: The constant force required to cut through dense rubber leads to chronic wrist, shoulder, and back problems.

- Falling Material Hazards: Improperly secured bales can shift or fall during manual cutting, potentially crushing or trapping workers.

- Ergonomic Issues: Poor posture during manual cutting operations contributes to long-term musculoskeletal disorders.

Real Impact:

- Average cost of a workplace laceration claim: $30,000–$50,000

- Lost workdays per cutting injury: 10–30 days

- Increased insurance premiums after claims: 15–40% annually

Automatic Bale Cutter Safety Advantages

Modern rubber bale cutters, like those manufactured by Vikas Industries, incorporate multiple safety features:

- Enclosed cutting chambers that prevent contact with blades

- Two-hand operation systems requiring deliberate engagement

- Emergency stop buttons for immediate shutdown

- Safety interlocks that prevent operation when guards are open

- Consistent, predictable cutting eliminating surprise springback

The elimination of direct blade contact alone reduces injury risk by approximately 95%.

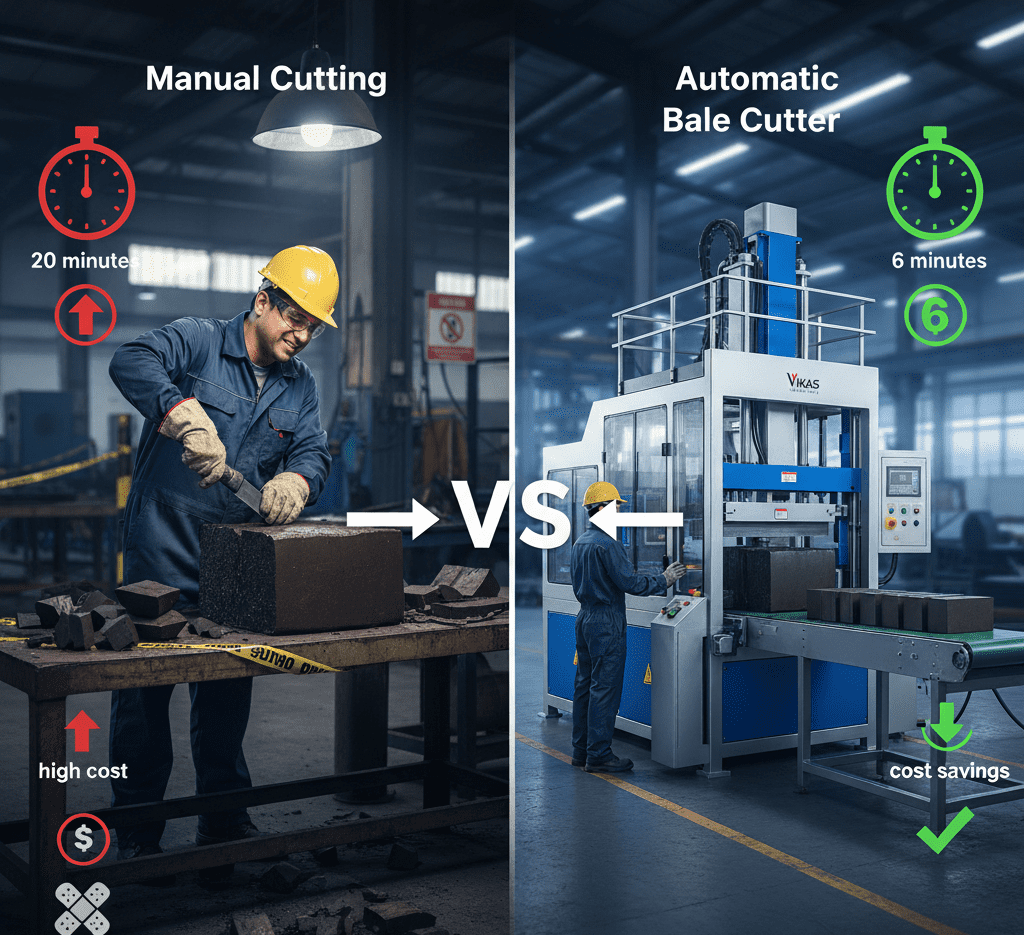

Speed and Efficiency Comparison

Processing Time Per Bale

Manual Cutting:

- Positioning and securing bale: 3–5 minutes

- Marking cut lines: 1–2 minutes

- Actual cutting: 8–12 minutes (depending on number of cuts)

- Cleanup and repositioning: 2–3 minutes

- Total time per bale: 14–22 minutes

- Bales processed per 8-hour shift: 22–34 bales

Automatic Bale Cutter:

- Loading bale into machine: 1–2 minutes

- Setting cut parameters: 30 seconds

- Automatic cutting cycle: 2–4 minutes

- Unloading cut pieces: 1–2 minutes

- Total time per bale: 4.5–8.5 minutes

- Bales processed per 8-hour shift: 56–106 bales

An automatic bale cutter processes rubber 2.5 to 3 times faster than manual methods, freeing up workers for higher-value tasks.

Consistency and Quality

Manual cutting inevitably produces inconsistent piece sizes. Even experienced workers can’t match the precision of hydraulic cutters, which maintain:

- Size variation of less than ±2mm

- Uniform thickness critical for downstream processing

- Clean cuts that reduce rubber waste

- Consistent feeding for rubber mixing mills and dispersion kneaders

This consistency directly impacts your rubber hydraulic press and extruder operations, reducing reject rates and improving product quality.

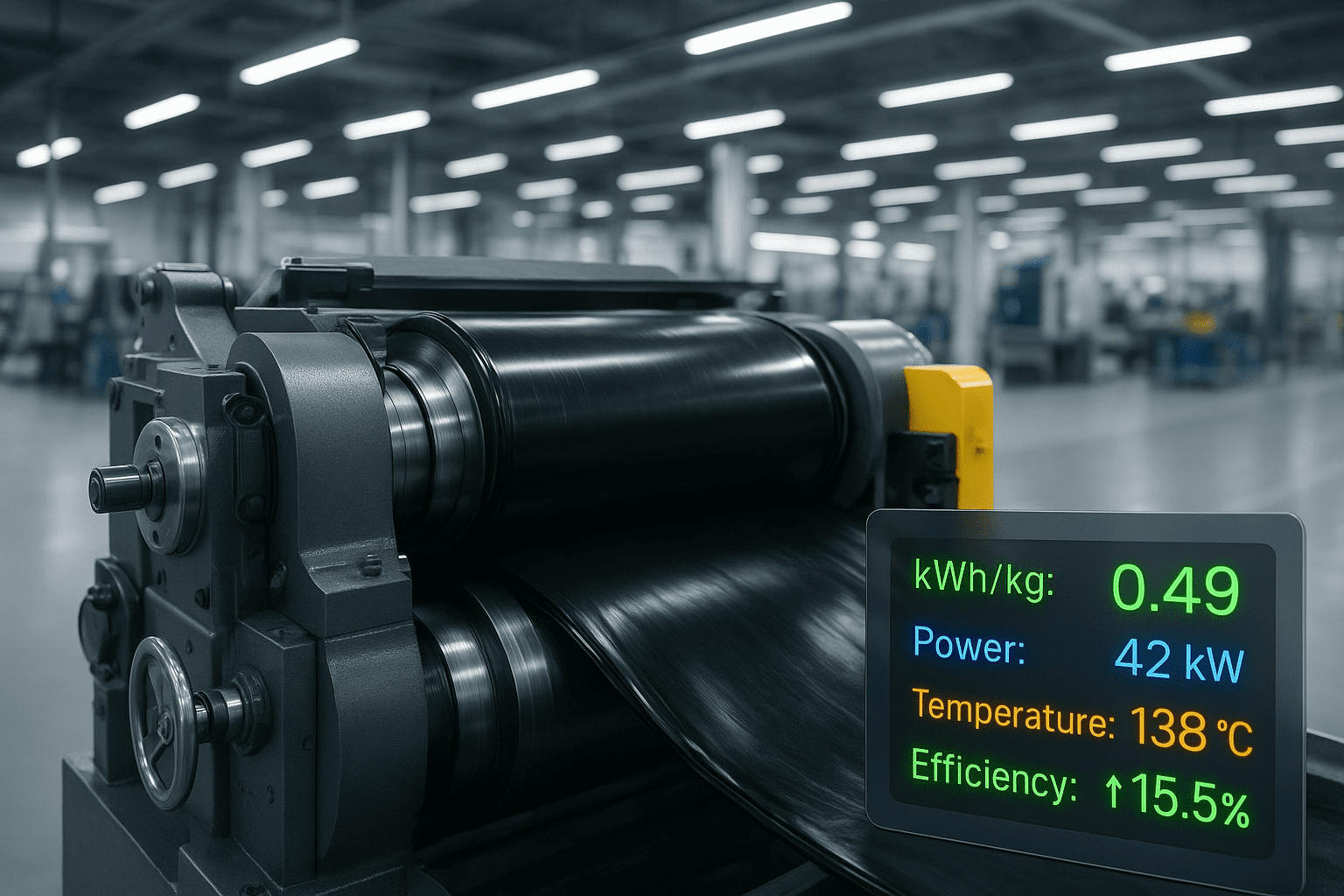

Environmental and Waste Considerations

Automatic bale cutters generate less waste through:

- Precise cutting that maximizes usable rubber from each bale

- Reduced rubber dust from cleaner cutting actions

- Better scrap management with predictable off-cuts

- Lower energy consumption per cut compared to powered hand tools running continuously

According to the Rubber Manufacturers Association, precision cutting can reduce raw material waste by 3–7%, translating to significant cost savings for high-volume operations.

Making the Decision: Is a Bale Cutter Right for You?

When Manual Cutting Might Still Make Sense

- You process fewer than 10 bales per week

- Your facility operates on an extremely limited budget

- You have abundant low-cost labor available

- Your cutting requirements are highly irregular

When You Absolutely Need an Automatic Bale Cutter

- You process 15+ bales weekly

- Worker safety is a top priority

- You’re experiencing worker compensation claims

- Downstream processes require consistent sizing

- You’re scaling production capacity

- Labor costs are increasing in your region

Downloadable Cost Calculator Spreadsheet

To help you make an informed decision, we’ve created a ready-to-use spreadsheet template that lets you input your specific numbers:

What’s Included:

- Initial investment comparison calculator

- 5-year cost projection model

- Labor cost calculator (adjustable hourly rates)

- ROI timeline with break-even analysis

- Safety cost estimator (injury frequency and costs)

- Production capacity calculator

- Annual savings summary

How to Use the Spreadsheet

- Enter your current labor costs and hours spent on manual cutting

- Input your average bales processed per week

- Add your estimated injury/insurance costs

- Review the automatic comparison with equipment quotes

- See your projected payback period and 5-year savings

Real-World Case Study: Mid-Size Rubber Processor

A tire component manufacturer in Gujarat was processing 60 bales weekly using four workers on rotating shifts. After implementing a hydraulic bale cutter from Vikas Industries:

Results after 12 months:

- Labor costs reduced by 62%

- Processing time cut from 18 hours to 6 hours weekly

- Zero cutting-related injuries (down from 3 minor incidents)

- Cut consistency improved reject rates by 14%

- Complete ROI achieved in 8.5 months

- Annual savings: ₹22,00,000 (~$27,000)

For more success stories and detailed machine specifications, visit our complete machinery catalog.

Frequently Asked Questions (FAQs)

1. How long does a rubber bale cutter last?

With proper maintenance, a quality hydraulic bale cutter typically lasts 15–25 years. Vikas Industries machines are built with industrial-grade components designed for continuous operation, with most customers reporting 20+ years of reliable service.

2. Can automatic bale cutters handle different rubber types and hardness levels?

Yes, modern bale cutters are designed to process various rubber compounds including natural rubber, SBR, EPDM, and nitrile rubber with varying hardness levels. The hydraulic pressure is adjustable to accommodate different material densities.

3. What maintenance is required for rubber bale cutters?

Routine maintenance includes hydraulic fluid checks (monthly), blade sharpening or replacement (every 3–6 months depending on volume), lubrication of moving parts (weekly), and annual professional inspection. Total maintenance time averages 2–3 hours monthly.

4. Do I need special training to operate a rubber bale cutter?

Basic operation training takes 2–4 hours and covers safety protocols, loading procedures, cut adjustment, and emergency procedures. Most operators become fully proficient within 2–3 days. Vikas Industries provides comprehensive training with equipment purchase.

5. How much space does a rubber bale cutter require?

Standard models require approximately 6–10 square meters of floor space, including loading and unloading areas. Compact models are available for facilities with space constraints. Specific dimensions vary by model capacity.

6. Can bale cutters be integrated with existing rubber processing lines?

Yes, bale cutters work seamlessly with existing equipment including mixing mills, internal mixers, and extruders. Many facilities position them directly upstream of their mixing equipment for streamlined material flow. Vikas Industries can provide layout consultation for optimal integration with your current setup.

Conclusion: The Cutting-Edge Decision

The data is clear: while manual rubber cutting appears cheaper initially, automatic bale cutters deliver superior ROI through labor savings, injury prevention, increased speed, and improved quality. For any facility processing more than 15 bales weekly, the investment typically pays for itself in under one year.

The question isn’t whether you can afford a rubber bale cutter—it’s whether you can afford not to have one.

Ready to transform your rubber processing operation? Contact Vikas Industries today for a customized quote and see how much you could save with automated bale cutting.

Related Resources

- How to Choose the Right Rubber Mixing Mill for Your Production Needs

- Dispersion Kneader Maintenance Guide: Maximizing Equipment Lifespan

About Vikas Industries

Vikas Industries is a leading manufacturer of rubber processing machinery, specializing in Rubber Hydraulic Presses, Rubber Mixing Mills, Dispersion Kneaders, Rubber Bale Cutters, and Hot Feed & Cold Feed Extruders. With decades of experience serving the rubber manufacturing industry, we provide reliable, high-performance equipment designed for Indian manufacturing conditions.

Get Your Custom Quote: Visit www.vikasindustriesmachinery.com or contact our technical team to discuss your specific requirements.