In the rubber processing industry, efficiency and safety aren’t just buzzwords—they’re the foundation of profitable operations. One piece of equipment that dramatically impacts both metrics is the rubber bale cutter. For manufacturers processing hundreds of rubber bales weekly, the difference between manual cutting and automated systems can mean the difference between accidents and smooth operations, between bottlenecks and optimized throughput.

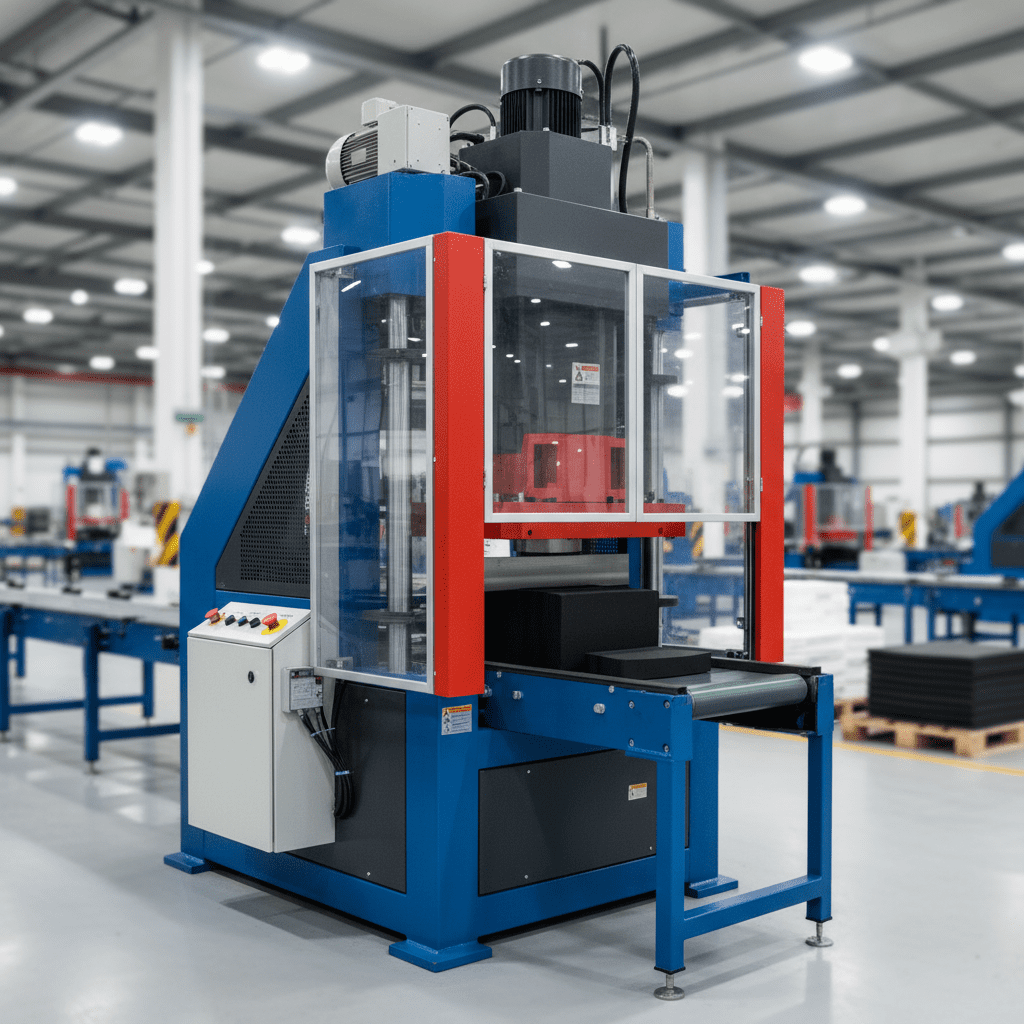

At Vikas Industries, we’ve spent decades engineering rubber processing machinery that addresses real-world challenges faced by rubber manufacturers. Our Rubber Bale Cutter represents years of innovation focused on one critical question: How can we make bale cutting faster, safer, and more consistent?

This article dives into the tangible benefits of automated rubber bale cutters, backed by real plant data, safety improvements, and operational metrics that matter to production managers and plant supervisors.

The Hidden Dangers of Manual Rubber Bale Cutting

Before exploring the rubber bale cutter benefits, let’s address why this equipment matters so much for worker safety.

Natural and synthetic rubber bales typically weigh between 33-35 kg (73-77 lbs) and arrive compressed and wrapped in packaging. Manually cutting these bales involves sharp tools, repetitive motions, and significant physical strain. Workers face several hazards:

- Laceration risks from knives or cutting wires

- Musculoskeletal injuries from repetitive cutting motions and handling heavy bales

- Crushing injuries when bales spring open unexpectedly after cutting

- Eye injuries from flying debris or packaging material

- Ergonomic issues from awkward postures during cutting

“We had a close call last year when a worker was cutting a compressed bale and it sprang open, hitting his shoulder. He was off work for two weeks. That incident alone justified our investment in automated bale cutting—no amount of production is worth risking someone’s livelihood,” shares Rajesh Kumar, Production Supervisor at a tire manufacturing plant in Pune.

According to the Rubber Manufacturers Association, handling and preparation tasks account for approximately 18% of recordable injuries in rubber processing facilities. Automated cutting systems virtually eliminate this risk category.

What Makes Automated Bale Cutting Different?

Modern automated bale cutting systems like those manufactured by Vikas Industries use hydraulic mechanisms to precisely cut rubber bales without human intervention in the danger zone. Here’s how the process works:

- Loading: Operators place wrapped rubber bales onto the feeding platform

- Positioning: Hydraulic systems position the bale for optimal cutting

- Cutting: Heavy-duty blades powered by hydraulic pressure slice through the bale cleanly

- Discharge: Cut sections are automatically discharged for the next processing stage

The entire cycle takes 15-30 seconds per bale, depending on bale size and rubber hardness—significantly faster than manual methods while keeping operators at a safe distance.

Key Features of Industrial Rubber Bale Cutters

Hydraulic Power System: Delivers consistent cutting force (typically 20-50 tons) regardless of rubber hardness or operator strength

Adjustable Cutting Size: Allows customization of cut dimensions to match downstream equipment like Rubber Mixing Mills or Dispersion Kneaders

Safety Interlocks: Prevents operation when guards are open or when hands are in the cutting zone

Robust Construction: Heavy-duty steel frames and hardened cutting blades withstand continuous operation

Easy Maintenance: Accessible components and straightforward blade replacement minimize downtime

Real Plant Data: Throughput Improvements

Let’s examine actual data from facilities that implemented automated bale cutting systems.

Case Study: Mid-Size Rubber Compound Manufacturer

Facility: 3-shift operation processing 200 rubber bales daily Previous Method: Manual cutting with handheld toolsImplementation: Vikas Industries Rubber Bale Cutter installation

Results after 6 months:

| Metric | Manual Cutting | Automated Cutting | Improvement |

|---|---|---|---|

| Bales processed/hour | 8-10 | 22-25 | +140% |

| Labor required | 2 workers | 1 worker | -50% |

| Processing time/bale | 6-7 minutes | 2.5 minutes | -64% |

| Cutting consistency | Variable | Uniform | N/A |

| Workplace injuries | 3 minor/year | 0 | -100% |

Bale Cutter Throughput: The Numbers Speak

The throughput advantage becomes even more significant in larger operations. A facility processing 500 bales daily can expect:

- Time savings: 30-35 hours per week in direct cutting time

- Labor reallocation: 2-3 workers can be reassigned to higher-value tasks

- Reduced bottlenecks: Cutting no longer limits downstream processes like mixing or extrusion

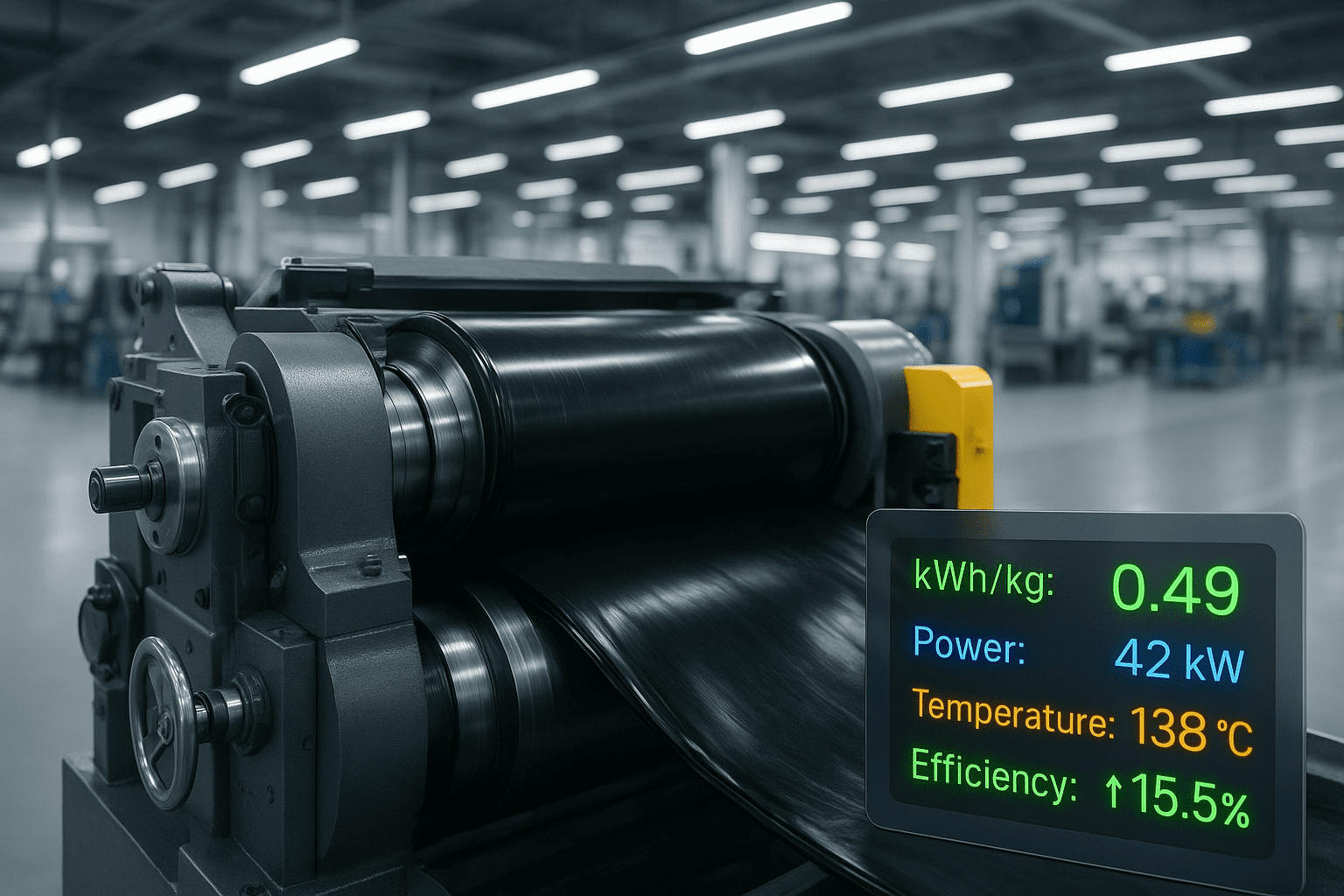

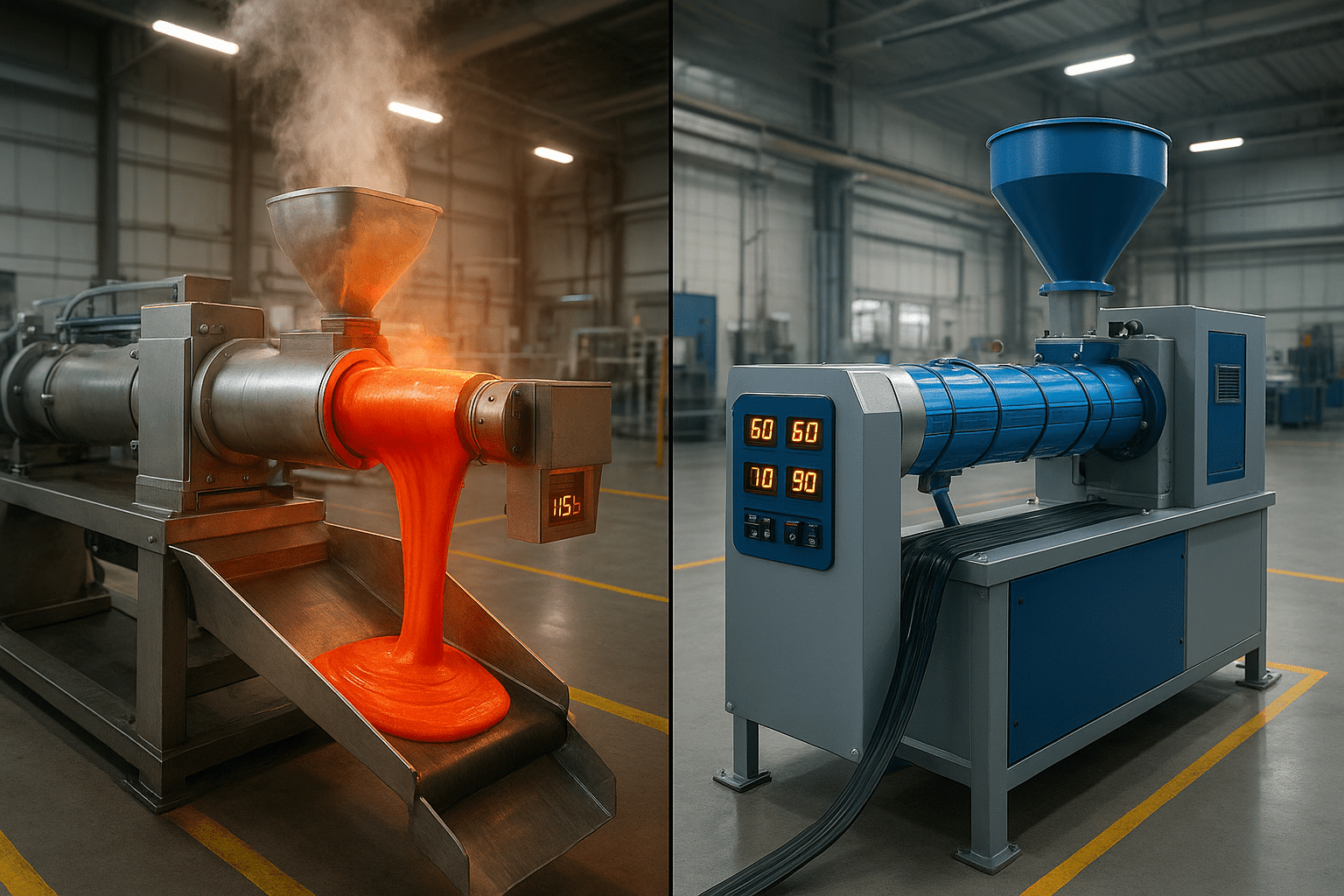

- Consistency: Uniform cut sizes improve feeding efficiency for Hot Feed & Cold Feed Extruders

One automotive rubber parts manufacturer reported that after installing automated bale cutters, their Rubber Mixing Millutilization increased by 23% simply because properly sized, consistently cut rubber improved feeding efficiency.

Safety Improvements: Beyond Injury Prevention

The safety benefits of automated rubber bale cutters extend beyond eliminating cutting injuries:

Reduced Physical Strain: Workers no longer perform repetitive cutting motions, decreasing cumulative trauma disorders and chronic pain complaints.

Improved Air Quality: Enclosed cutting chambers with optional dust collection systems reduce rubber dust exposure during cutting.

Better Housekeeping: Controlled cutting and discharge reduce scattered packaging materials and rubber scraps, creating a cleaner, safer work environment.

Predictable Operations: Automation eliminates variability caused by worker fatigue, especially during night shifts or during peak production periods.

Compliance Advantages: Meeting OSHA standards and safety regulations becomes simpler with guarded, automated systems that feature documented safety protocols.

According to OSHA guidelines for rubber manufacturing, machine guarding and automation are among the most effective methods for preventing injuries in material handling operations.

ROI and Operational Benefits

While safety is paramount, the financial case for automated bale cutting is equally compelling:

Direct Cost Savings:

- Reduced labor costs (fewer workers needed)

- Lower workers’ compensation insurance premiums

- Decreased injury-related downtime and replacement worker costs

- Reduced material waste from inconsistent cutting

Indirect Benefits:

- Faster production cycles allow for increased overall output

- Consistent cut sizes optimize performance of downstream equipment

- Better inventory management through faster processing

- Enhanced quality control through standardized preparation

Most facilities report ROI within 12-18 months, with larger operations seeing payback in under a year.

Integration with Your Rubber Processing Line

A rubber bale cutter doesn’t operate in isolation—it’s the first critical step in your processing chain. At Vikas Industries, we design our bale cutters to integrate seamlessly with other rubber processing equipment:

Upstream: Accepts bales in standard packaging, accommodating variations in bale size and wrapping

Downstream: Produces consistently sized cuts that feed efficiently into:

- Rubber Mixing Mills for compound blending

- Dispersion Kneaders for intensive mixing

- Rubber Hydraulic Presses for molding operations

- Hot Feed & Cold Feed Extruders for profile production

This integration creates a smooth material flow that maximizes overall equipment effectiveness (OEE) across your entire production line.

Choosing the Right Rubber Bale Cutter

Not all bale cutters are created equal. When selecting equipment for your facility, consider:

Capacity Requirements: Match the cutter’s throughput to your daily bale processing volume

Material Compatibility: Ensure the cutter handles your specific rubber types (natural rubber, SBR, EPDM, nitrile, etc.)

Cut Size Flexibility: Verify that adjustable settings match your downstream equipment requirements

Power Requirements: Confirm that your facility’s electrical infrastructure supports the hydraulic system

Safety Features: Look for comprehensive guarding, emergency stops, and safety interlocks

Service Support: Partner with manufacturers offering technical support, spare parts availability, and maintenance guidance

Vikas Industries provides comprehensive consultation to help you select the optimal configuration for your specific needs. Contact our team for personalized recommendations.

Maintenance Best Practices

To maximize the lifespan and performance of your rubber bale cutter:

Daily:

- Inspect blades for wear or damage

- Check hydraulic fluid levels

- Clean cutting area of debris

- Test safety interlocks

Weekly:

- Lubricate moving components

- Inspect hydraulic hoses for leaks

- Clean or replace air filters

Monthly:

- Check blade alignment and sharpness

- Inspect electrical connections

- Verify hydraulic pressure settings

- Review safety system functionality

Annually:

- Complete blade replacement

- Comprehensive hydraulic system inspection

- Professional safety system audit

- Structural integrity assessment

Well-maintained equipment not only lasts longer but also maintains consistent performance and safety standards.

The Future of Bale Cutting Technology

The rubber processing industry continues to evolve, and bale cutting technology evolves with it:

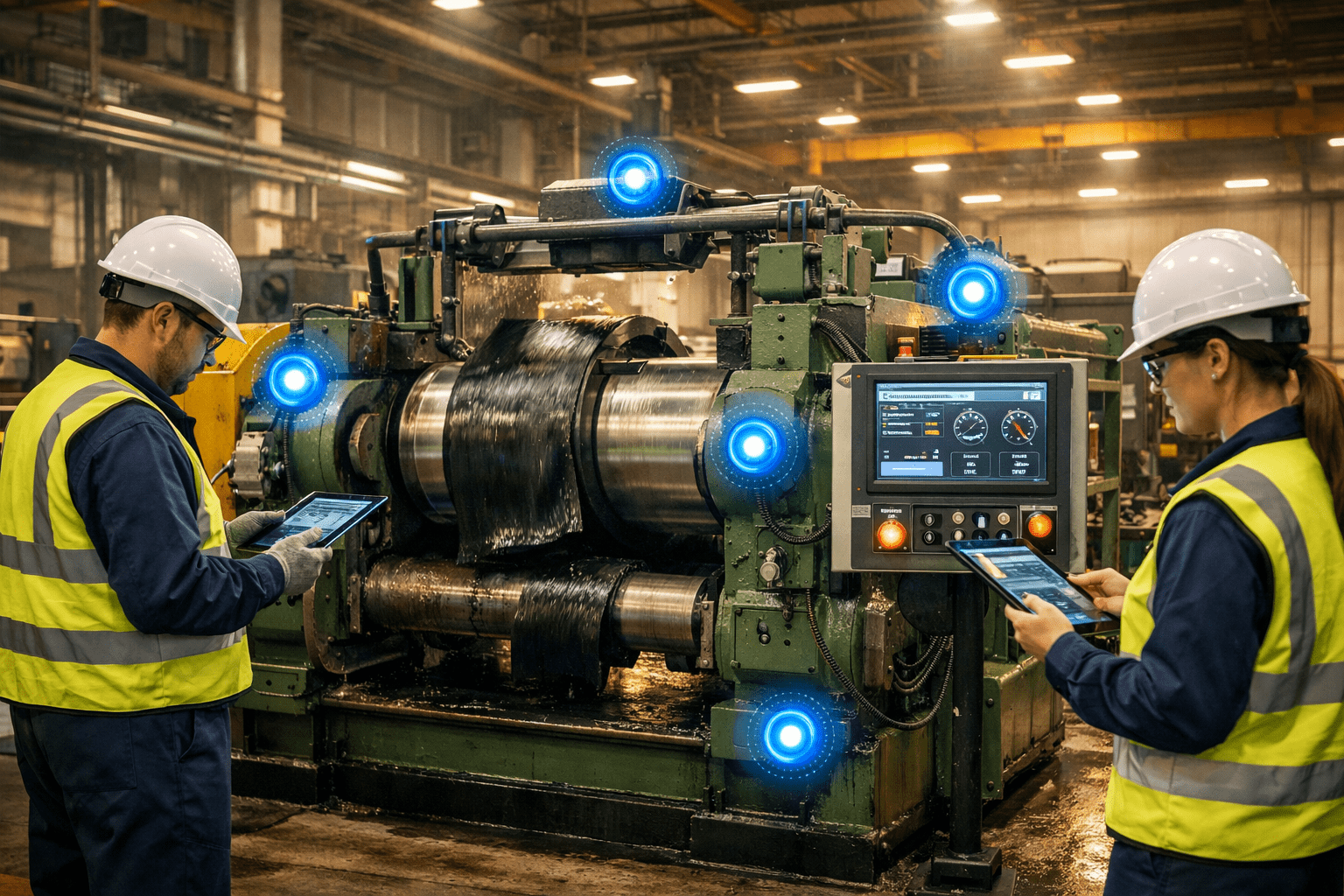

Smart Sensors: Next-generation systems incorporate sensors that detect rubber hardness and automatically adjust cutting parameters

Predictive Maintenance: IoT-enabled equipment monitors performance metrics and predicts maintenance needs before failures occur

Integration with Plant Systems: Advanced cutters connect to MES (Manufacturing Execution Systems) for real-time production tracking

Energy Efficiency: Improved hydraulic systems and power management reduce energy consumption

Enhanced Safety: Vision systems and advanced guarding provide additional layers of worker protection

At Vikas Industries, we continuously innovate to keep our rubber processing machinery at the forefront of industry technology.

Making the Investment Decision

If you’re still using manual bale cutting methods, the evidence is clear: automated systems deliver measurable improvements in safety, throughput, and operational efficiency.

Consider these questions:

- Are cutting operations creating bottlenecks in your production line?

- Have you experienced injuries or near-misses during manual bale cutting?

- Is inconsistent cutting affecting downstream process efficiency?

- Could labor reallocation improve your overall productivity?

- Are you expanding production capacity?

If you answered “yes” to any of these questions, it’s time to evaluate automated bale cutting solutions.

Request a quote from Vikas Industries today to discuss how our Rubber Bale Cutter can transform your operations. Our team can provide detailed specifications, arrange demonstrations, and develop a customized solution for your facility.

Conclusion

The rubber bale cutter benefits are undeniable: dramatic improvements in worker safety, consistent throughput increases of 140% or more, reduced labor costs, and better integration with downstream processes. Real plant data confirms what rubber manufacturers worldwide have discovered—automation in bale cutting isn’t just an improvement, it’s a necessity for competitive, safe operations.

As the rubber processing industry faces increasing pressure to improve efficiency while maintaining the highest safety standards, automated bale cutting represents a proven solution that delivers measurable results.

Vikas Industries has been manufacturing reliable, high-performance rubber processing machinery for decades. Our Rubber Bale Cutter incorporates the latest safety features, robust construction, and user-friendly operation to meet the demanding requirements of modern rubber processing facilities.

Whether you’re upgrading existing equipment or building a new processing line, we invite you to explore how our comprehensive range of machinery—including Rubber Hydraulic Presses, Rubber Mixing Mills, Dispersion Kneaders, and Extruders—can optimize your operations.

Ready to improve your bale cutting operations? Contact Vikas Industries today for expert consultation and discover how the right equipment can transform your rubber processing efficiency and workplace safety.

Frequently Asked Questions (FAQs)

Q1: How much does a rubber bale cutter typically cost?

A: Industrial rubber bale cutters typically range from $15,000 to $50,000 depending on capacity, features, and automation level. The investment usually pays for itself within 12-18 months through labor savings, reduced injuries, and increased throughput. Contact Vikas Industries for specific pricing based on your requirements.

Q2: What types of rubber can automated bale cutters process?

A: High-quality bale cutters can process all standard rubber types including natural rubber, SBR (Styrene-Butadiene Rubber), EPDM, nitrile, butyl, and other synthetic elastomers. Vikas Industries bale cutters are designed to handle varying rubber hardness levels and bale densities without adjustment issues.

Q3: How many workers are needed to operate a rubber bale cutter?

A: Most automated rubber bale cutters require only one operator to load bales and monitor the process. This represents a 50% reduction compared to typical two-person manual cutting operations, allowing labor reallocation to higher-value tasks.

Q4: What maintenance is required for rubber bale cutters?

A: Routine maintenance includes daily blade inspection, weekly lubrication, and monthly blade sharpening or replacement. Hydraulic systems require periodic fluid checks and filter changes. With proper maintenance, industrial bale cutters operate reliably for 10-15 years or more.

Q5: Can bale cutters be integrated with existing rubber processing equipment?

A: Yes, rubber bale cutters are designed to integrate seamlessly with downstream equipment like mixing mills, kneaders, and extruders. Vikas Industries provides consultation to ensure proper sizing and workflow integration with your existing rubber processing machinery.

Q6: What safety certifications should I look for in a rubber bale cutter?

A: Look for equipment that meets OSHA machine guarding standards, includes safety interlocks, emergency stop functions, and proper guarding. Vikas Industries designs all equipment to meet international safety standards and can provide documentation for compliance verification.

About Vikas Industries

Vikas Industries is a leading manufacturer of rubber processing machinery, serving rubber manufacturers worldwide with reliable, high-performance equipment. Our comprehensive product line includes Rubber Hydraulic Presses, Rubber Mixing Mills, Dispersion Kneaders, Rubber Bale Cutters, and Hot Feed & Cold Feed Extruders.

Visit www.vikasindustriesmachinery.com to explore our complete catalog or contact our team for personalized consultation.