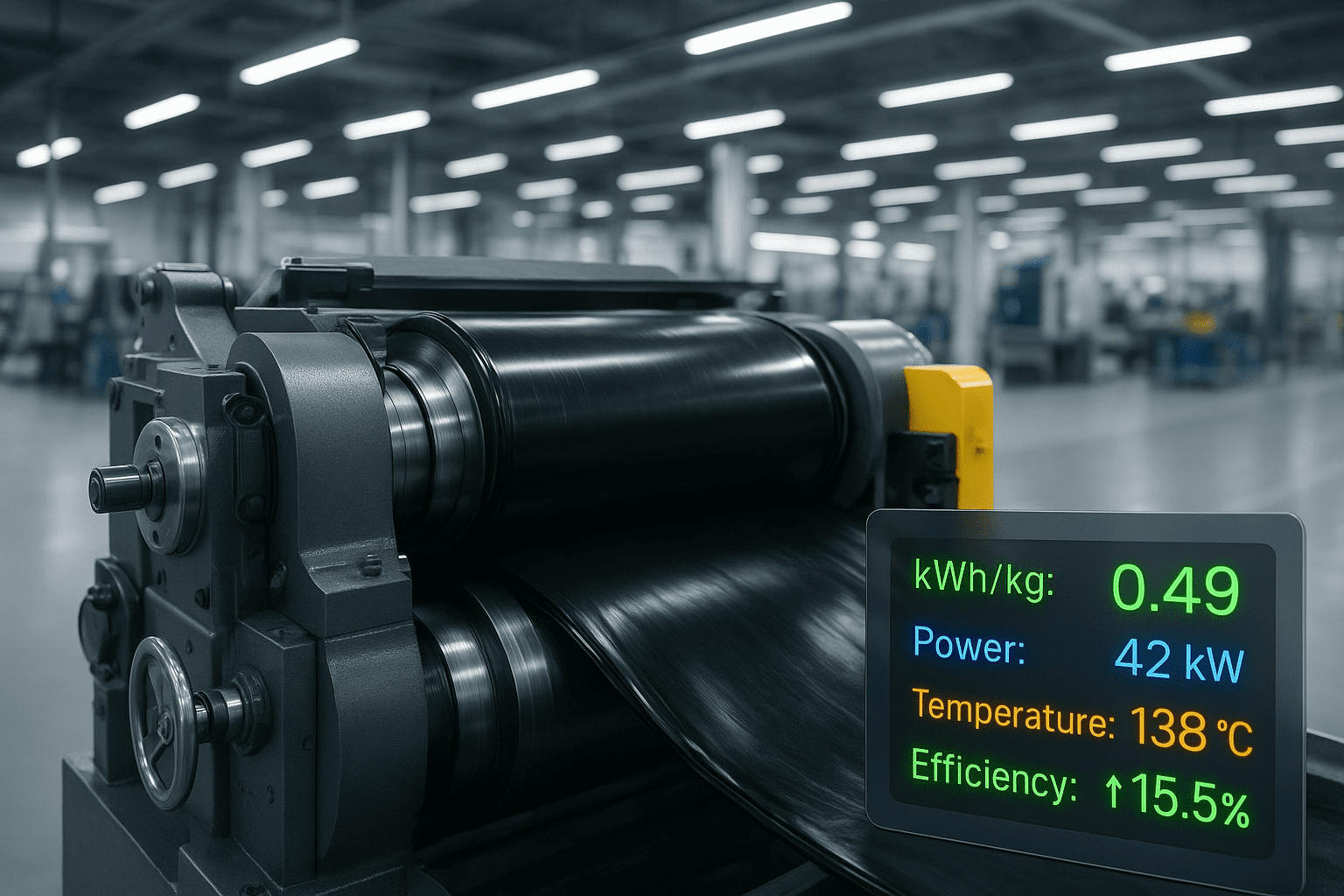

When the production manager at a mid-sized rubber components plant in Gujarat walked into his facility one Monday morning, he faced a familiar problem: nearly 15% material waste from their 20-year-old rubber mixing mill, but no data to explain why. The machine still worked—it mixed compounds reliably—but it was essentially blind. No sensors tracked batch consistency, no alerts flagged temperature drift, and certainly no dashboard showed real-time efficiency metrics.

Three months later, after a modest retrofit investment of ₹3.5 lakhs, that same mill was streaming live data to the cloud, predicting maintenance needs, and waste had dropped to 6%. The machine didn’t get younger, but it got smarter.

This is the promise of retrofitting rubber machinery for Industry 4.0—and it’s more accessible than most plant owners realize.

What Does Industry 4.0 Mean for Rubber Manufacturing?

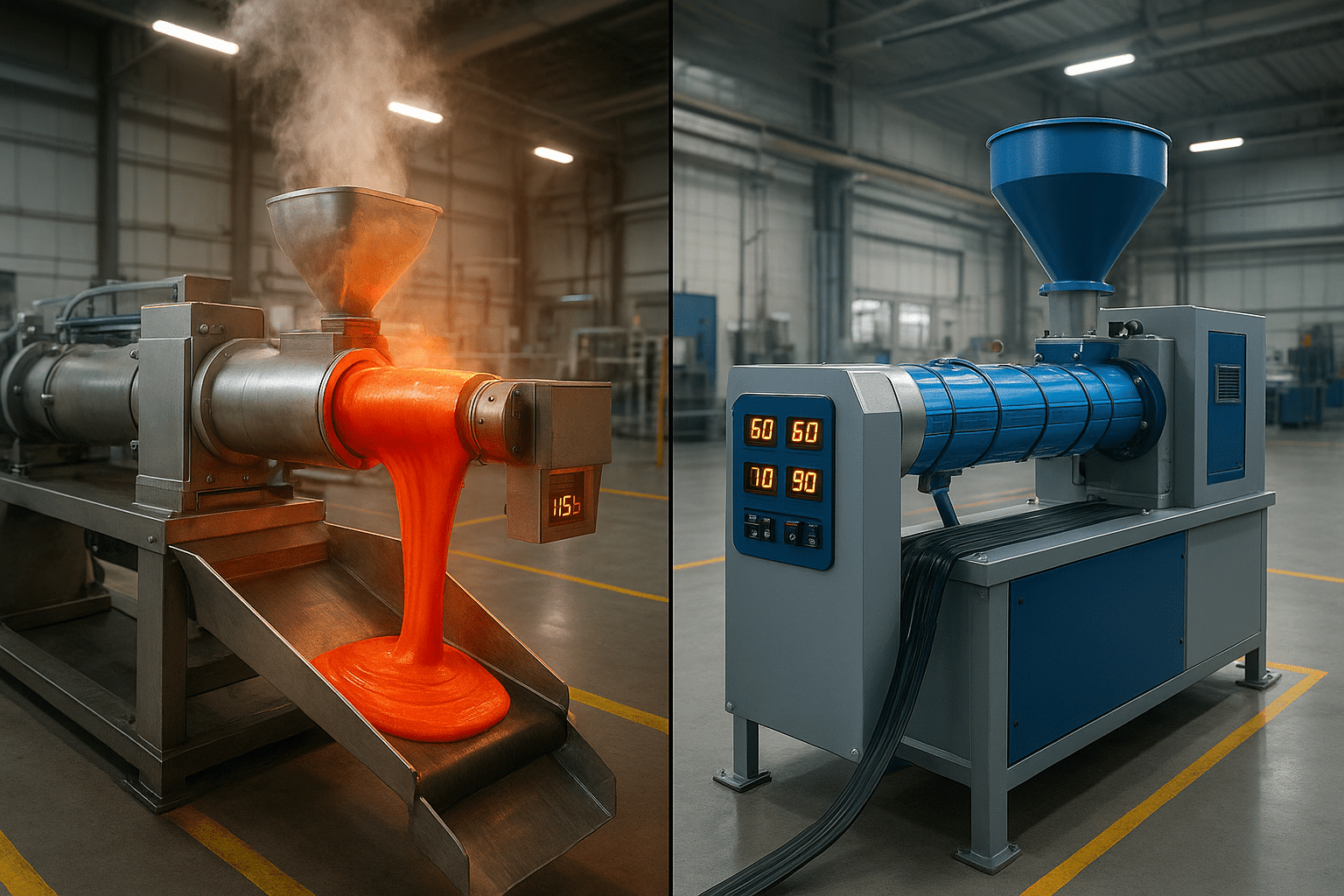

Industry 4.0 isn’t about ripping out functional equipment and buying brand-new smart machines. It’s about connecting, monitoring, and optimizing what you already have. For rubber processing plants, this means transforming legacy equipment like rubber mixing mills, hydraulic presses, dispersion kneaders, and extruders into intelligent assets that communicate, self-diagnose, and drive better decisions.

The core technologies include smart sensors for temperature and pressure monitoring, IoT gateways that push data to the cloud, predictive maintenance algorithms that prevent unexpected breakdowns, and real-time dashboards accessible from your phone or office computer.

According to a McKinsey study on smart manufacturing, companies that embrace digital retrofitting see 10-30% reductions in maintenance costs and 15-25% improvements in equipment effectiveness. For rubber plants operating on thin margins, these numbers aren’t abstract—they translate directly to lakhs saved annually.

Why Retrofit Instead of Replace?

The elephant in every boardroom: why not just buy new machines?

Cost reality: A new smart rubber mixing mill can cost ₹25-40 lakhs. Retrofitting an existing mill with sensors, controls, and connectivity typically runs ₹3-8 lakhs depending on complexity. That’s 80-90% savings while achieving many of the same benefits.

Proven reliability: Your 15-year-old hydraulic press already works. Its mechanical systems are battle-tested. You’re simply adding a nervous system to an already strong body.

Faster deployment: Installing new machinery means downtime for removal, installation, and operator training. Retrofits can often be done during scheduled maintenance windows, minimizing production loss.

Sustainability: The rubber industry is under increasing pressure to reduce its environmental footprint. Extending equipment life through smart upgrades is more sustainable than scrapping functional machines.

The Quick Wins: Where to Start Your Retrofit Journey

1. Temperature and Pressure Sensors on Mixing Mills

The problem: Inconsistent batch quality, periodic scorching, operator-dependent results.

The solution: Install digital temperature sensors on mill rollers and compound contact points, plus pressure sensors on hydraulic systems. These relay real-time data to a simple dashboard.

Cost: ₹80,000 – ₹1.5 lakhs per mill

Payback period: 6-12 months through reduced waste and consistent quality

A rubber hose manufacturer in Pune added sensors to three aging rubber mixing mills and discovered that compound temperatures were spiking 15°C above optimal during certain shifts. The cause? Operators adjusting roller gaps inconsistently. With visible feedback, they standardized the process and cut rejection rates by 40%.

2. Vibration Monitoring on Hydraulic Presses

The problem: Unexpected breakdowns, costly emergency repairs, production stoppages.

The solution: Attach vibration sensors to critical moving parts of your rubber hydraulic press. Machine learning algorithms detect anomalies that precede failures—worn bearings, misalignment, hydraulic issues.

Cost: ₹1.2 – ₹2.5 lakhs per press

Payback period: One prevented breakdown often covers the investment

Predictive maintenance isn’t fortune-telling. It’s pattern recognition. According to research from the International Society of Automation, vibration analysis can detect bearing problems 2-3 weeks before catastrophic failure, giving you time to schedule repairs during planned downtime.

3. Production Counters and Cycle Time Tracking

The problem: No visibility into actual equipment utilization, guesswork for capacity planning.

The solution: Simple digital counters track press cycles, extruder run time, or kneader batches. Data flows to a central system showing OEE (Overall Equipment Effectiveness).

Cost: ₹50,000 – ₹1.2 lakhs for basic tracking across multiple machines

Payback period: Immediate through better planning and utilization insights

One rubber products plant discovered their dispersion kneader was sitting idle 22% of operating hours simply due to poor scheduling between compounding and molding departments. Visibility led to workflow redesign and a 15% capacity increase with zero capital investment in new equipment.

4. Energy Monitoring Systems

The problem: Rising electricity costs, no data on which machines consume most power.

The solution: Install smart energy meters on individual machines—mixing mills, hot feed extruders, cold feed extruders, hydraulic power packs.

Cost: ₹40,000 – ₹1 lakh for comprehensive monitoring

Payback period: 12-18 months through energy optimization

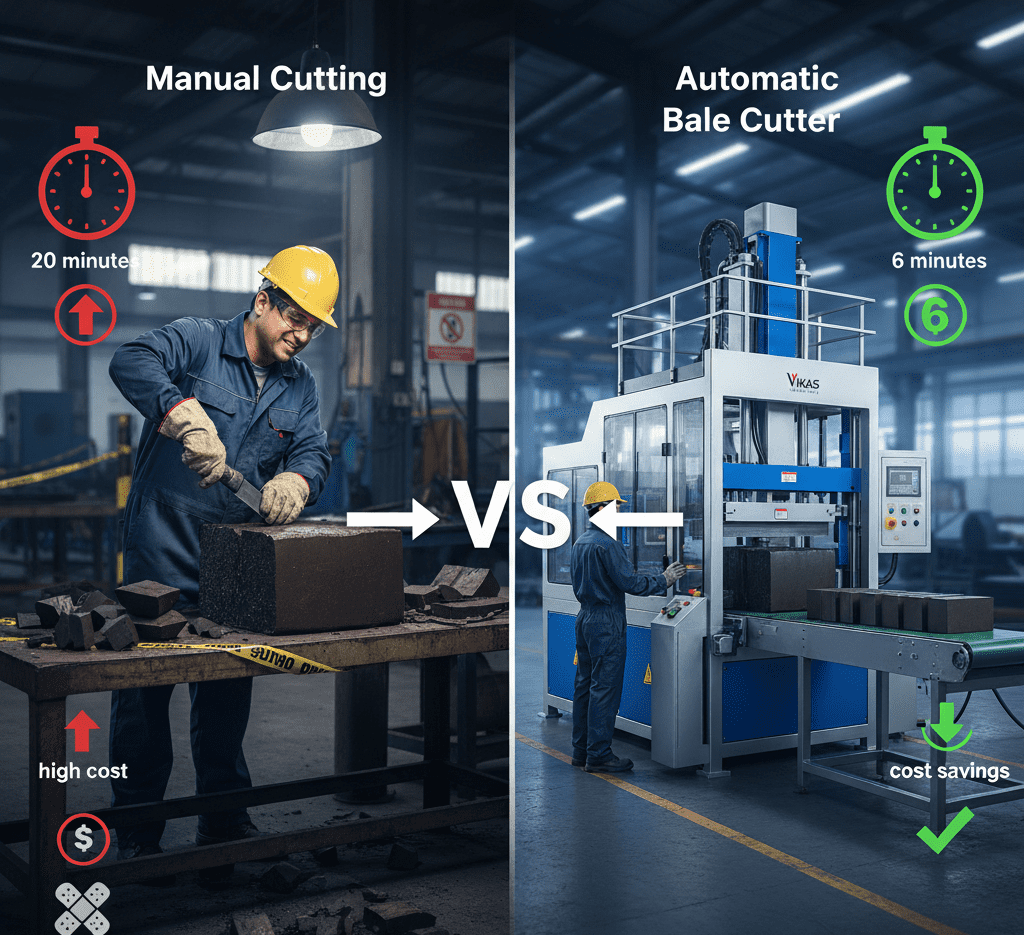

Energy represents 15-25% of rubber processing costs. A Maharashtra plant found their rubber bale cutter was drawing excessive current due to dull blades—an issue invisible until they added monitoring. Timely blade changes reduced energy consumption by 18% on that operation.

Real Numbers: What Does a Typical Retrofit Cost?

Here’s a realistic budget breakdown for retrofitting a small to medium rubber processing facility:

Basic package (single machine focus): ₹2.5 – ₹5 lakhs

- Sensors for one or two critical machines

- Basic data logging

- Simple alert system

- Minimal cloud integration

Intermediate package (line-level upgrade): ₹8 – ₹15 lakhs

- Sensors across 4-6 machines

- IoT gateway and cloud dashboard

- Predictive maintenance algorithms

- Mobile app access

- Historical data analysis

Comprehensive package (plant-wide transformation): ₹25 – ₹50 lakhs

- Full sensor deployment across mixing mills, presses, kneaders, extruders

- Integrated ERP connectivity

- Advanced analytics and AI

- Energy management system

- Training and change management support

Most plants see positive ROI within 18-24 months through combined savings in maintenance, energy, waste reduction, and improved throughput.

The Benefits Beyond Cost Savings

Quality Consistency

Smart sensors eliminate the guesswork. When every batch of compound is mixed at precisely monitored temperatures and pressures, variation plummets. This is particularly crucial for automotive and industrial rubber products where specifications are tight.

Compliance and Traceability

Industry 4.0 systems automatically log every parameter—time, temperature, operator, raw material batch. If a customer raises a quality concern six months later, you have complete traceability. This documentation also simplifies ISO audits and customer certifications.

Workforce Empowerment

Contrary to fears that automation eliminates jobs, retrofitting typically upskills your workforce. Operators evolve from manual adjusters to data-informed decision-makers. Machine tenders become predictive maintenance technicians. According to research from the World Economic Forum, manufacturing companies adopting Industry 4.0 see net job growth as roles shift toward higher-value activities.

Competitive Positioning

When you can quote shorter lead times, guarantee tighter tolerances, and demonstrate real-time production visibility to customers, you’re no longer competing solely on price. You’re offering reliability and partnership.

Overcoming Common Retrofit Challenges

“Our machines are too old to retrofit”

Almost any rubber processing equipment with electrical or hydraulic systems can be retrofitted. Even purely mechanical machines can have sensors added externally. The key is working with partners who understand both rubber processing and industrial IoT—not just one or the other.

“We don’t have IT expertise in-house”

Modern retrofit solutions are designed for manufacturing environments, not IT departments. Cloud-based platforms handle the complexity behind simple interfaces. Many providers, including specialized machinery manufacturers like Vikas Industries, offer turnkey solutions with ongoing support.

“Our internet connectivity is unreliable”

Edge computing solves this. Data is processed locally on-site, with only summary information sent to the cloud when connectivity allows. Critical alerts and controls work independently of internet access.

“We’ll lose our competitive processes to competitors”

Data security is legitimate. Choose retrofit partners with robust cybersecurity, encrypted communications, and data sovereignty options. Your process know-how stays protected while you gain analytical advantages.

Getting Started: A Practical Roadmap

Month 1: Assessment

Identify your highest-impact machines—typically those with frequent issues, quality variability, or high operating costs. Audit current maintenance logs and production data to establish baselines.

Month 2: Pilot Project

Start with one machine and one clear goal. Install sensors, establish data flow, and test alerts. This de-risks the investment and builds internal expertise.

Month 3-4: Measure and Refine

Collect data, analyze results, and calculate actual ROI. Document operator feedback and address usability issues.

Month 5-12: Scale Up

Apply learnings to additional equipment. Build the business case for expanded deployment based on proven results, not projections.

Ongoing: Continuous Improvement

Use accumulated data to optimize recipes, scheduling, and maintenance. Industry 4.0 isn’t a project—it’s a capability that compounds over time.

Why Partner with Experienced Machinery Manufacturers?

Generic IoT vendors can install sensors, but they don’t understand the nuances of rubber processing—mill nip gaps, kneader ram pressure curves, extruder screw speeds, or hydraulic press timing. Manufacturers who build rubber equipment inherently understand these variables.

At Vikas Industries, we’ve spent decades manufacturing rubber hydraulic presses, rubber mixing mills, dispersion kneaders, rubber bale cutters, and both hot feed and cold feed extruders. Our retrofit solutions are designed by engineers who understand that a temperature spike during mixing isn’t just a number—it indicates compound scorching risk that affects final product properties.

When you work with machinery specialists, you get sensors placed at points that actually matter, alert thresholds set based on real process limits, and dashboards that surface insights relevant to rubber manufacturing—not generic factory metrics.

Explore our complete range of rubber processing equipment and retrofit capabilities at our machinery catalog.

The Bottom Line: Start Small, Think Big

You don’t need to digitize your entire plant overnight. You don’t need unlimited budgets or a team of data scientists. You need to start with one machine, one measurable goal, and a partner who understands both rubber processing and smart manufacturing.

The rubber industry has always been about precision—precise temperatures, pressures, timing. Industry 4.0 simply gives you the tools to achieve that precision consistently, efficiently, and profitably with the equipment you already own.

The question isn’t whether to retrofit your rubber machinery. The question is: what will you retrofit first?

Ready to explore retrofit options for your rubber processing equipment? Visit Vikas Industries or contact our technical team for a customized assessment of your facility.

Frequently Asked Questions

Q: How long does it take to retrofit a rubber mixing mill with Industry 4.0 sensors?

A: Most single-machine retrofits take 3-7 days including sensor installation, calibration, and operator training. Installation is typically done during scheduled maintenance windows to minimize production disruption.

Q: Can we retrofit machines from different manufacturers?

A: Yes. Industry 4.0 retrofit solutions are manufacturer-agnostic. Whether you have mixing mills from different suppliers or a hydraulic press from another brand, sensors and connectivity can be added. The key is understanding the specific machine parameters and critical monitoring points.

Q: What’s the minimum investment to see meaningful results?

A: A focused retrofit on a single critical machine—such as adding temperature monitoring to a mixing mill or vibration analysis to a hydraulic press—typically costs ₹80,000 to ₹2 lakhs and can deliver measurable waste reduction or maintenance savings within 6-12 months.

Q: Will retrofitting void my equipment warranty?

A: Non-invasive sensor installations and external monitoring systems typically don’t affect warranties. If your equipment is still under warranty, discuss retrofit plans with the original manufacturer. For older equipment past warranty periods, this is not a concern.

Q: Do we need to hire additional staff to manage Industry 4.0 systems?

A: Not necessarily. Modern systems are designed for existing operators and maintenance teams with basic smartphone/computer skills. Initial training (typically 1-3 days) enables your current workforce to interpret dashboards and respond to alerts. Some plants designate one technically-minded team member as the “digital champion” to coordinate with retrofit partners.

Q: How do we prioritize which machines to retrofit first?

A: Focus on machines with the highest impact: those causing quality issues, experiencing frequent breakdowns, or consuming significant energy. Analyze maintenance logs, scrap rates, and downtime records. Often, one problematic machine—like an aging dispersion kneader with inconsistent batch quality—becomes the obvious starting point with the clearest ROI.

Related Resources:

- Choosing the Right Rubber Mixing Mill for Your Production Needs

- Preventive Maintenance Checklist for Rubber Hydraulic Presses

- Request a Custom Quote for Rubber Processing Equipment

Looking to modernize your rubber processing operations? Vikas Industries combines 40+ years of machinery manufacturing expertise with Industry 4.0 retrofit capabilities. Let’s discuss how smart sensors and connectivity can transform your existing equipment.