Rubber manufacturers face increasing pressure to trim operational costs without sacrificing product quality. Energy consumption stands out as one of the biggest expenses—especially in extrusion and mixing operations where machines run continuously at high temperatures and pressures.

For facilities processing 500+ kg of rubber daily, energy costs likely consume 15–25% of your production budget. The real challenge? Most manufacturers remain unaware of where they’re losing energy. Even worse, many believe energy efficiency requires trading output or quality.

The truth is different. Through strategic operational shifts and smart equipment choices, leading rubber processors have slashed energy consumption by 12–28% while maintaining production rates and product specs. This blog reveals exactly how.

Understanding Energy Consumption in Rubber Processing

Let’s start with the basics before diving into solutions. Energy efficiency in rubber processing is typically measured as kWh per kilogram (kWh/kg) of finished rubber. Essentially, this KPI shows how much electrical energy your machines need to process one kilogram of material.

According to the Rubber Manufacturers Association (RMA), understanding energy consumption patterns is critical for gaining competitive advantage in the industry.

Here are typical industry benchmarks:

- Mixing mills: 0.45–0.65 kWh/kg

- Hot feed extruders: 0.55–0.75 kWh/kg

- Cold feed extruders: 0.35–0.50 kWh/kg

If your facility exceeds these ranges, you have room for efficiency gains. Similarly, if you’re close to these numbers, even incremental improvements still deliver meaningful returns.

Consider this example: A mid-sized rubber processor handles 1,000 kg per day at 0.60 kWh/kg. That’s 600 kWh daily, translating to roughly 180,000 kWh annually. At India’s average industrial electricity rate of ₹7–8 per kWh, that amounts to ₹12.6–14.4 lakhs yearly on machine energy alone.

A modest 15% reduction saves ₹1.89–2.16 lakhs per year—money that flows directly to your profit margin.

The Three Biggest Energy Drains in Rubber Extrusion & Mixing

1. Inadequate Temperature Management

Rubber processing machines reach peak efficiency within a narrow thermal window. When material runs too cold, it resists movement, forcing motors to work harder. Conversely, excessive heat wastes energy on unnecessary thermal load.

The problem is clear: Many facilities rely on outdated temperature control systems that overshoot targets by 5–10°C. An extruder running at 150°C instead of 140°C may seem minor—but across an 8-hour shift, that overage wastes 15–20% of thermal energy.

Cold feed extruders face particular sensitivity here. Without proper pre-conditioning, incoming rubber demands additional mechanical work to reach processing temperature, spiking energy demand significantly.

2. Worn Equipment and Loose Tolerances

When mixing mills and extruders develop worn screws, barrels, or rollers, internal slippage occurs. The motor spins normally, but material moves slower than designed. Consequently, torque and amp draw increase substantially.

Picture this scenario: A mixing mill with worn rollers consumes 0.65 kWh/kg when optimal performance should deliver 0.50 kWh/kg. That represents a 30% efficiency loss—directly caused by deferred maintenance.

3. Improper Batch Composition and Feed Rate

Not every material composition requires identical energy inputs. Loaded compounds (containing high filler content like carbon black or silica) demand more mixing energy than unfilled rubbers. Additionally, poor feed rate control—whether too fast or too slow—creates turbulence and resistance, increasing motor load.

Furthermore, inconsistent incoming rubber quality (moisture content, contamination) forces operators to compensate with longer mixing times or elevated temperatures. This practice inevitably inflates energy consumption across your operation.

The One Low-Cost Change That Saved a Plant Real Money

Let me share a real-world case study that illustrates these principles in action.

The Facility: A medium-sized rubber components manufacturer in Tamil Nadu processes 800 kg of SBR and NBR daily across two mixing mills and one hot feed extruder.

The Problem: Energy bills climbed 8% year-on-year, which initially seemed like normal growth. However, energy per kilogram (kWh/kg) was also increasing—a red flag revealing efficiency degradation rather than simple volume expansion.

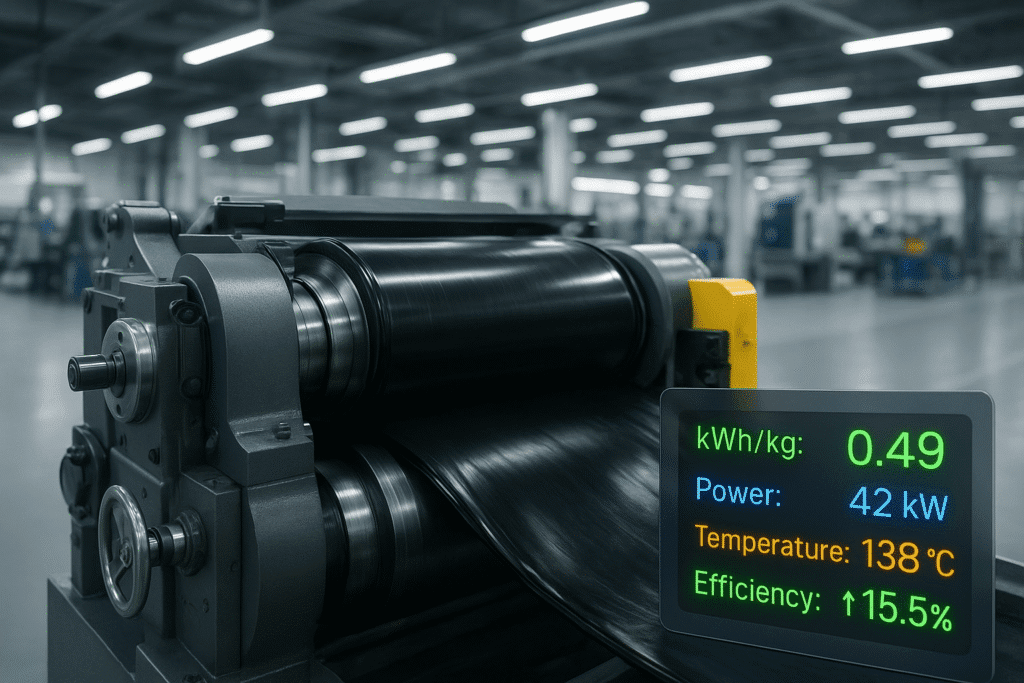

The Audit: Our team conducted a three-day energy assessment and uncovered a critical issue: mixing mills were running 15–20 minutes longer than necessary per batch. Material reached optimal plasticity (viscosity for processing) 20–25% faster than operators realized. Yet they continued mixing by routine—following outdated standard operating procedures instead of monitoring actual material readiness.

The Low-Cost Fix: Install basic mill discharge temperature monitoring using ₹8,000–12,000 worth of digital thermocouples and a simple data logger. Subsequently, train operators to discharge material at a predetermined optimal temperature (based on material science, not guesswork) rather than mixing for fixed periods.

The Result:

- Mixing time reduced by 18% (from 12 minutes to 9.8 minutes per batch)

- kWh/kg dropped from 0.58 to 0.49 (a 15.5% improvement)

- Annual energy savings: ₹2.84 lakhs

- ROI on equipment: 1 month

- Zero impact on product quality; batch consistency improved due to controlled discharge

This facility recovered its investment in just 4 weeks and has sustained these gains for 18+ months—proving that efficiency and profitability work together.

Four Strategic Changes to Reduce Energy Consumption

1. Optimize Temperature Control Systems

Action: Retrofit mixing mills and extruders with proportional-integral-derivative (PID) temperature controllers or upgrade existing systems to modern digital variants.

Modern industrial control systems, as detailed by the International Society of Automation (ISA), have revolutionized precision in rubber processing by enabling dynamic thermal management.

Why it works: PID controllers maintain temperature within ±2°C of setpoint, preventing overshoot and energy waste. In contrast, older on-off systems might swing ±5–8°C, wasting significant thermal energy.

Energy impact: 8–12% reduction in heating energy Cost: ₹35,000–60,000 per machine (mixing mill or extruder) Payback period: 8–14 months

2. Implement Preventive Maintenance on a Schedule

Action: Establish quarterly inspections and maintenance for mixing mill rollers, extruder screws, and barrel surfaces. Replace worn components proactively rather than waiting for reactive repairs.

Why it works: Equipment operating at 100% mechanical efficiency requires less electrical energy to achieve the same throughput. When machines run optimally, they deliver more output per watt.

Energy impact: 10–20% reduction (cumulative over time as wear is prevented) Cost: ₹20,000–40,000 per quarter per facility Payback period: 6–10 months

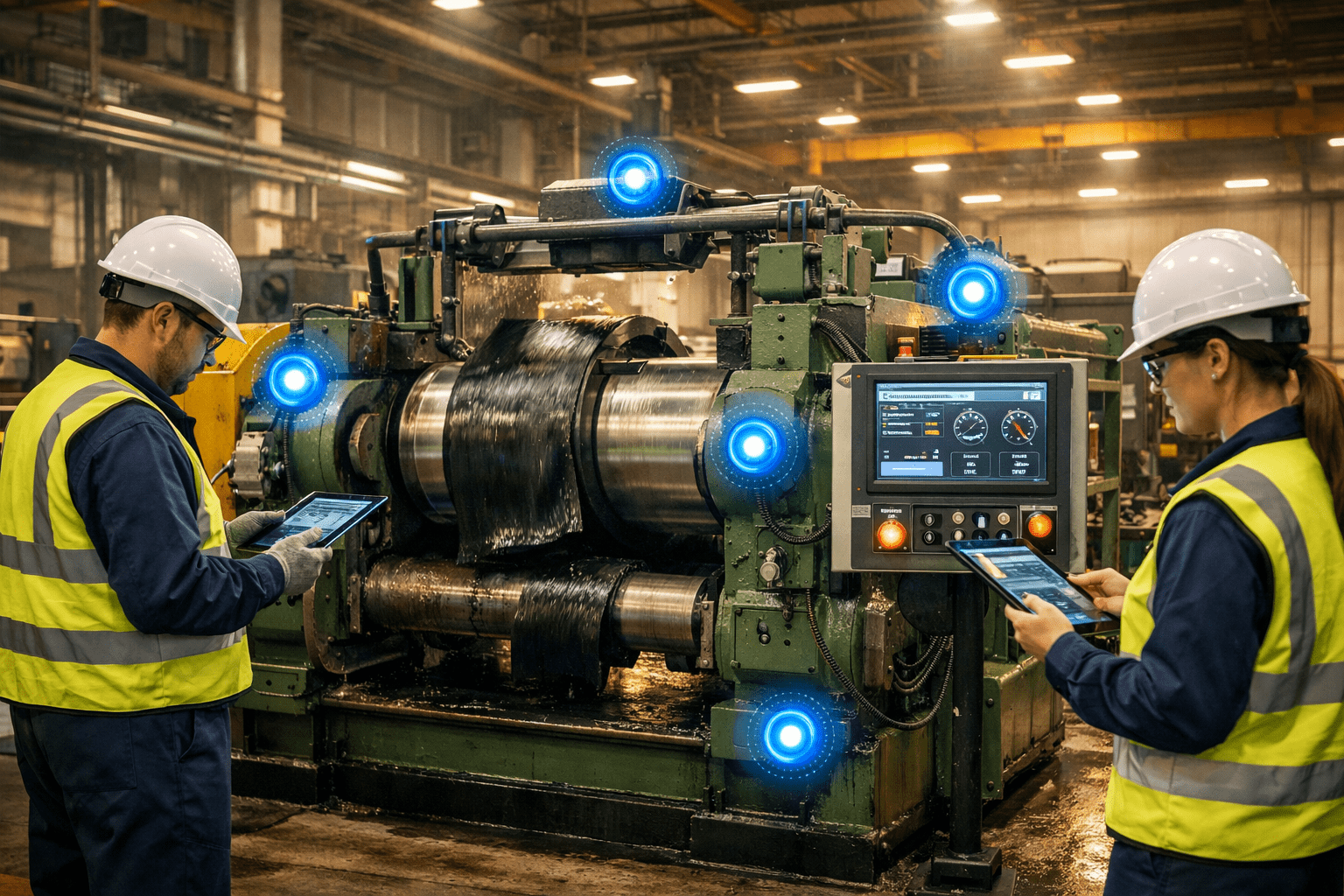

3. Install Batch Monitoring and Control Systems

Action: Use temperature, torque, and pressure sensors to provide real-time feedback to operators. Next, implement digital SOPs that adjust mixing time or extruder speed based on actual material behavior rather than fixed timers.

Why it works: Material readiness varies depending on incoming rubber quality, ambient conditions, and compound formulation. Fixed manual processes are inherently inefficient because they ignore these variables.

Energy impact: 5–15% reduction in mixing and extrusion energy Cost: ₹80,000–150,000 for a two-machine setup Payback period: 10–16 months

4. Pre-condition Incoming Rubber

Action: For cold feed extruders, introduce a simple feed conditioner or storage system that maintains rubber at 15–20°C above ambient before extrusion begins.

Why it works: Material entering the extruder closer to processing temperature requires less mechanical energy to reach optimal viscosity. Cold feed extruders designed to heat material from ambient temperature are inherently less efficient than those processing pre-warmed stock.

Energy impact: 10–18% reduction in cold feed extruder energy demand Cost: ₹60,000–120,000 (depending on throughput capacity) Payback period: 12–18 months

Key Performance Indicators You Should Track

To manage energy efficiency effectively, monitor these five essential KPIs on a monthly basis:

kWh per kilogram of rubber processed – This is your primary metric. Your goal should be reducing it by 5% every quarter for the first year, then maintaining those gains.

Machine runtime hours versus material output – This identifies when machines are running inefficiently. Track this metric as “kg per machine hour” for clear visibility.

Specific heat consumption – For heated machines like mills and extruders, separate heating energy from mechanical mixing or extrusion energy. This breakdown shows exactly where gains are available.

Power factor – Industrial facilities often face penalties for poor power factor. Maintaining PF above 0.95 saves 2–5% on overall energy charges.

Ambient production temperature – Document ambient temperature daily and correlate it with energy consumption. This reveals how much external conditions affect your process efficiency.

Common Equipment Upgrades Vikas Industries Recommends

If you’re considering equipment replacement or upgrade, focus on these key improvements for better energy efficiency.

Rubber Mixing Mill Upgrades: Modern mixing mills feature improved roller design, superior heat distribution, and tighter mechanical tolerances. Newer machines often deliver 15–20% better energy efficiency compared to models manufactured during 2010–2015.

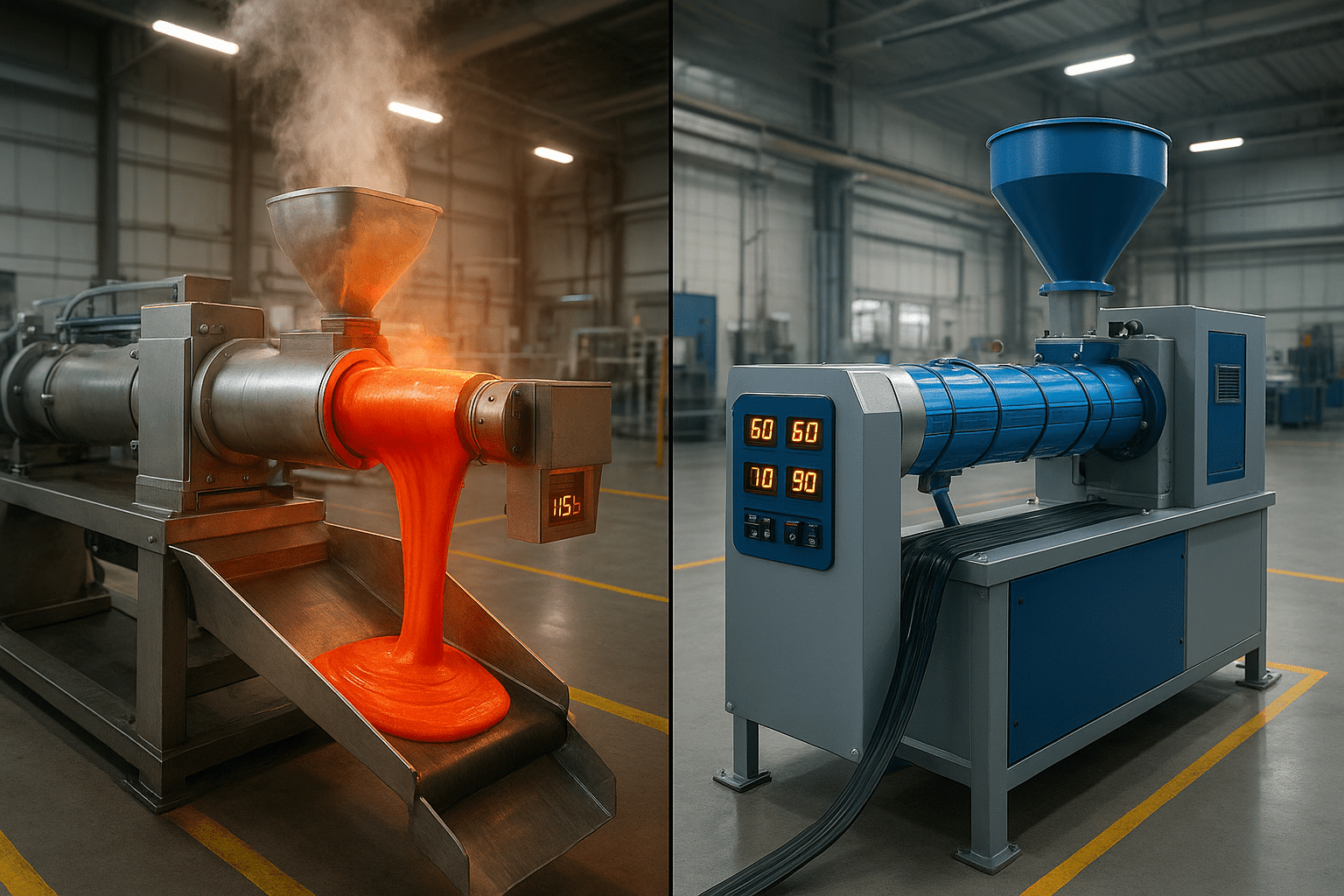

Hot Feed Extruder Specifications: When shopping for hot feed extruders, request machines equipped with variable frequency drives (VFDs) and proportional cooling systems. These components allow dynamic adjustment of screw speed and barrel temperature based on real-time material viscosity, saving 12–18% energy versus fixed-speed machines.

Cold Feed Extruder Configuration: Always ensure your cold feed extruder includes a feed throat heater and insulated hopper. This single feature reduces overall energy consumption by 8–12% on its own.

Vikas Industries manufactures industry-leading Rubber Mixing Mills, Hot Feed Extruders, and Cold Feed Extruders specifically engineered for maximum energy efficiency. Our machines meet international standards and come with digital control systems included as standard.

Real-World Energy Reduction Roadmap

Here’s a practical timeline for implementing these changes and seeing measurable results:

Month 1–2:

- Conduct a professional energy audit (₹0–15,000)

- Install basic monitoring equipment (₹10,000–20,000)

- Optimize existing SOPs at no cost (₹0)

- Expected savings: 5–8%

Month 3–4:

- Upgrade temperature control systems (₹35,000–60,000)

- Implement a preventive maintenance schedule (₹25,000)

- Expected additional savings: 5–10%

Month 5–8:

- Install batch monitoring and control systems (₹80,000–150,000)

- Fine-tune all process parameters based on data (₹0)

- Expected additional savings: 5–12%

By Month 9: You’ll achieve cumulative energy reduction of 15–28%, with payback on all investments completed.

FAQ: Energy Efficiency in Rubber Processing

Q1: How accurate must my kWh/kg baseline be before I can measure improvements?

A: You need at least two weeks of baseline data, measured consistently using power meters (₹3,000–8,000) rather than utility bills alone. Daily variations matter significantly. Once you have baseline data accurate to ±5%, you can confidently measure 2–3% improvements.

Q2: Can I improve energy efficiency without purchasing new equipment?

A: Absolutely. Operational improvements typically deliver 10–15% savings independently. Equipment upgrades then compound gains to 20–30%+. Start with operational changes; upgrade equipment on your normal replacement cycle.

Q3: Does improving energy efficiency negatively affect product quality?

A: No. When implemented correctly, energy efficiency improvements often enhance consistency and quality. This happens because you’re running processes at optimal parameters rather than compensating for inefficiency. Energy waste typically correlates with quality drift in the opposite direction.

Q4: How often should I recalibrate or audit my energy consumption?

A: Conduct a formal energy audit every 12 months or whenever equipment changes occur. Review kWh/kg metrics monthly as part of routine operations. If trends worsen, investigate immediately—wear develops gradually, and early detection prevents 20–30% efficiency drops.

Q5: What’s the typical ROI for energy efficiency projects in rubber processing?

A: Most well-planned projects deliver 12–24 month ROI on investments. The case study mentioned above (15.5% kWh/kg reduction) achieved 1-month ROI. Budget conservatively and assume 60–70% of projected savings materialize, and you’ll still see strong financial returns.

Q6: Should I prioritize mixing mill efficiency or extruder efficiency first?

A: Audit both machines thoroughly. Generally, gains are available in both areas. However, mixing mills often show lower-hanging fruit because their thermal load is easier to manage and control. Start there if your budget is limited, then progress to extruders.

Next Steps: Get Your Energy Efficiency Plan

Energy efficiency in rubber processing isn’t theoretical—it’s practical, measurable, and immediately profitable. Facilities that take action reduce costs while strengthening overall competitiveness.

If you’re ready to reduce your kWh/kg consumption and reclaim thousands in annual savings, Vikas Industries is here to help. We design and supply Rubber Processing Machinery specifically engineered for efficiency, and we offer professional consultation on process optimization.

Request a free energy assessment or machinery consultation—completely obligation-free. Our team will analyze your current process, identify savings opportunities specific to your operation, and recommend actionable solutions tailored to your needs.

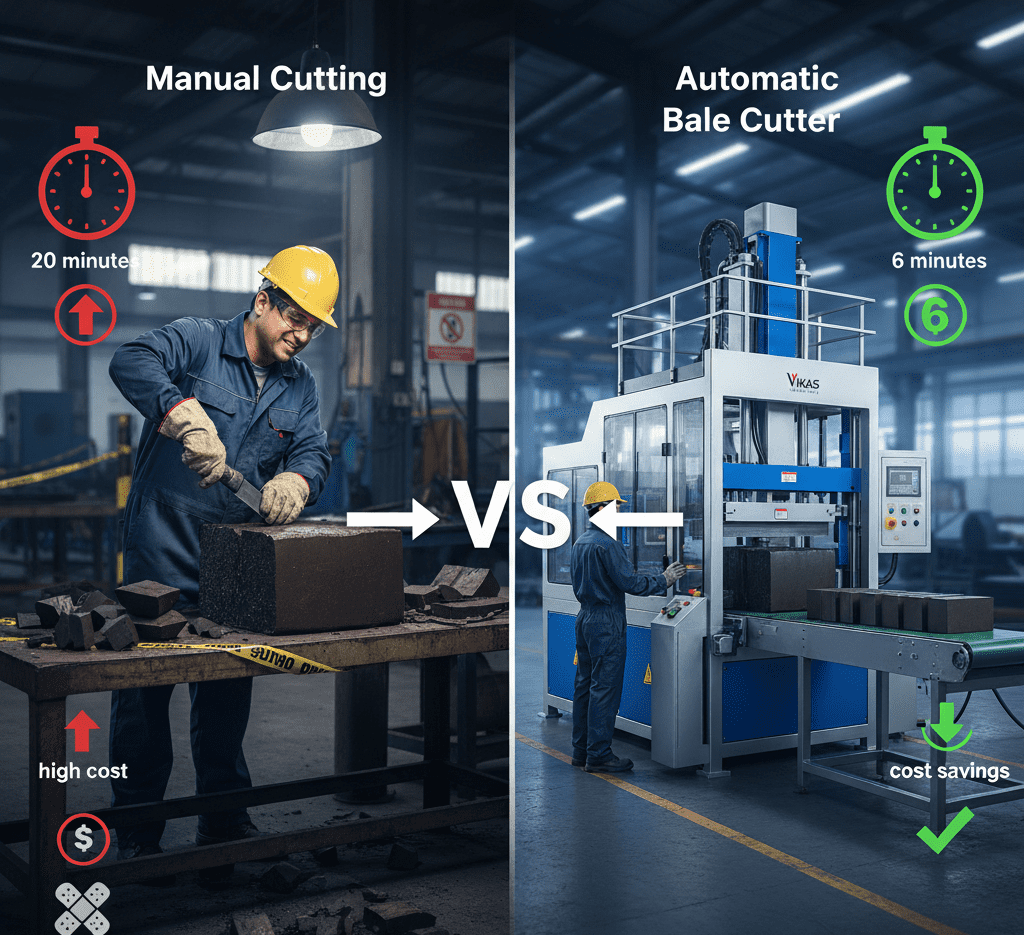

Alternatively, explore our complete Machinery Catalog to see how our Rubber Hydraulic Press, Dispersion Kneader, and Bale Cutter can complement your efficiency roadmap.

Related Reading

Explore these complementary topics to deepen your knowledge of rubber processing optimization:

Process Optimization for Rubber Mixing: Best Practices – Specific techniques for maximizing output without energy penalties.

Choosing Between Hot Feed and Cold Feed Extruders: A Comparative Guide – Understand energy trade-offs between different extrusion technologies.

Vikas Industries: Powering Efficient Rubber Processing Since [Year]. Learn more at www.vikasindustriesmachinery.com