The rubber industry is experiencing a major shift. Modern rubber mixing mills are changing how companies make rubber products. These new machines use smart technology to work faster and better than ever before.

This change matters because rubber mixing is the heart of making rubber products. From car tires to medical devices, everything starts with good mixing. The latest innovations are making this process smarter, cleaner, and more cost-effective.

What Are Modern Rubber Mixing Mills?

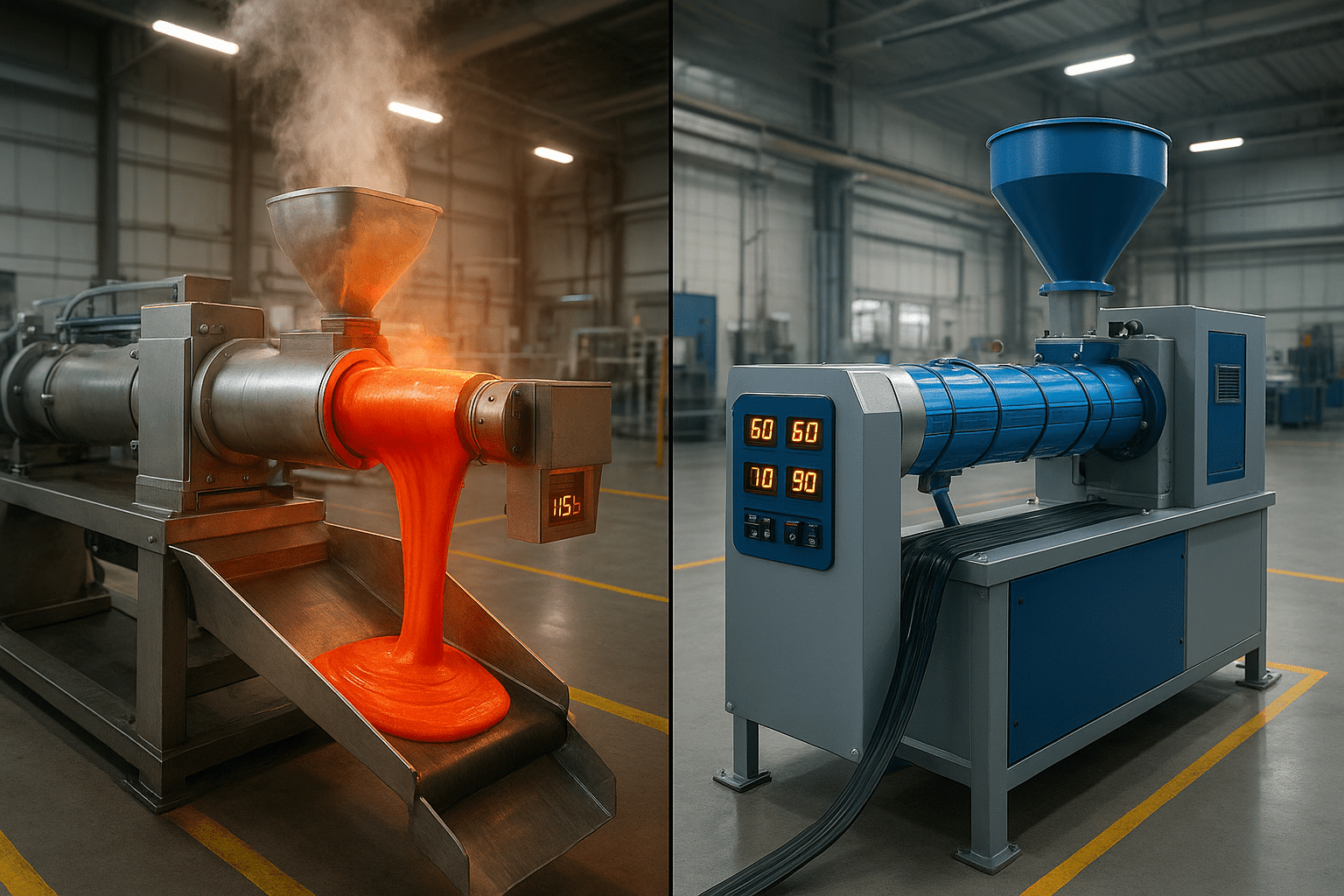

Modern rubber mixing mills are advanced machines that blend raw rubber with other materials. Unlike old mixing machines, these new systems use computers and sensors to control every step. They can mix different types of rubber with exact amounts of chemicals and additives.

These machines have two main rolling cylinders that work together. The cylinders squeeze and fold the rubber mixture many times. This creates a smooth, even blend that meets exact quality standards.

The key difference with modern systems is their smart controls. Sensors watch temperature, pressure, and mixing time. Computer systems adjust these settings automatically. This means better quality and less waste.

Key Features of Modern Mixing Mills:

- Computer-controlled temperature systems

- Automatic pressure adjustment

- Real-time quality monitoring

- Energy-saving motors

- Safety sensors and emergency stops

Automated Rubber Mixing Technology: The Smart Revolution

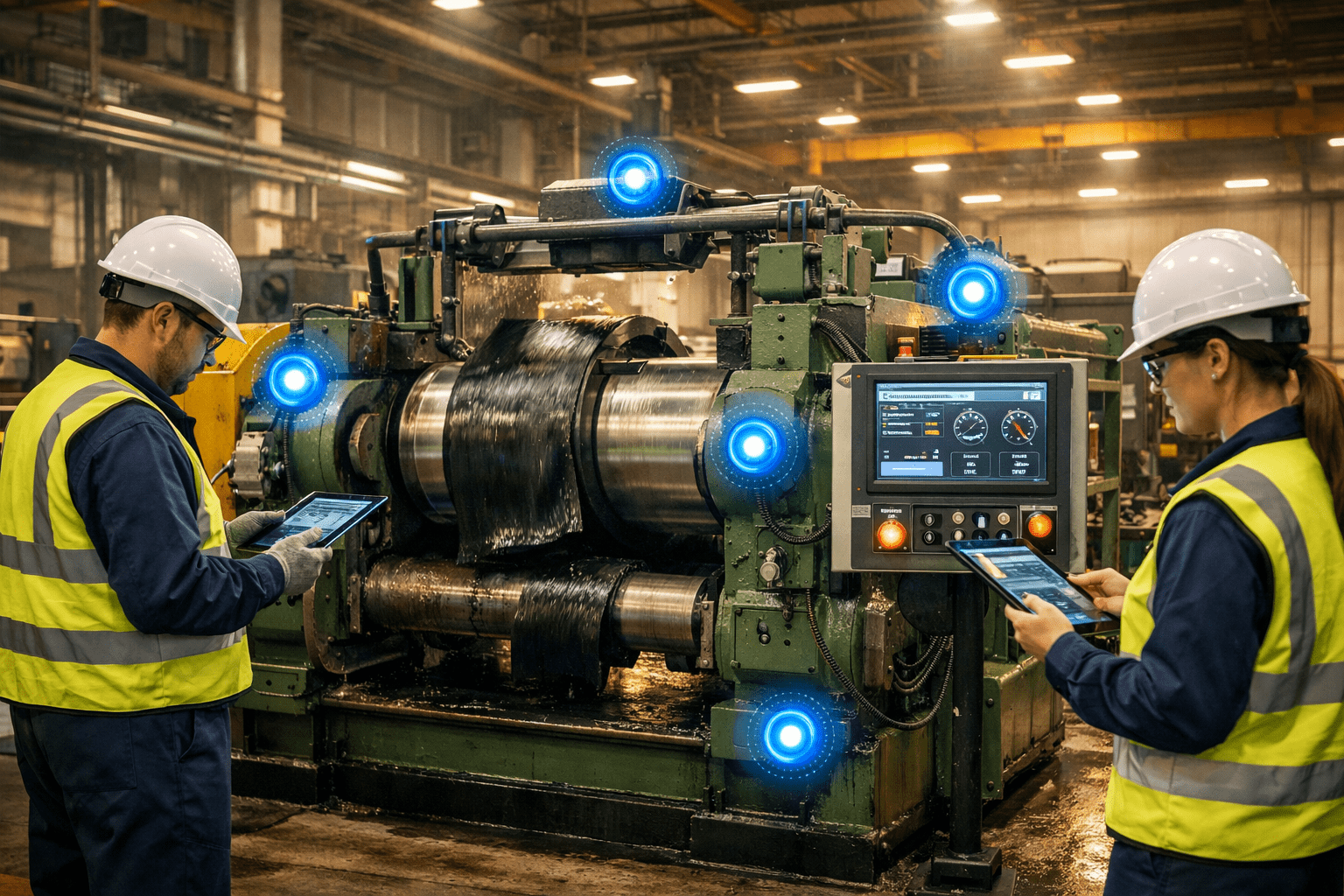

Automated rubber mixing technology is changing everything. These systems can run with very little human help. Workers set up the recipe, and the machine does the rest.

Smart sensors measure everything during mixing. They check if the rubber is the right thickness. They watch the temperature to prevent overheating. If something goes wrong, the system stops and alerts workers.

This automation helps companies make consistent products. Every batch comes out exactly the same. This is crucial for industries like aerospace and medical devices where quality cannot vary.

Benefits of Automated Systems:

- Consistent product quality

- Reduced human error

- 24/7 operation capability

- Better worker safety

- Detailed production records

The systems also learn from each batch. Artificial intelligence analyzes data to improve future mixing cycles. This makes the process better over time without human input.

https://thetechplast.com/blog/automated-rubber-mixing-systems

Energy-Efficient Mixing Mills: Going Green While Saving Money

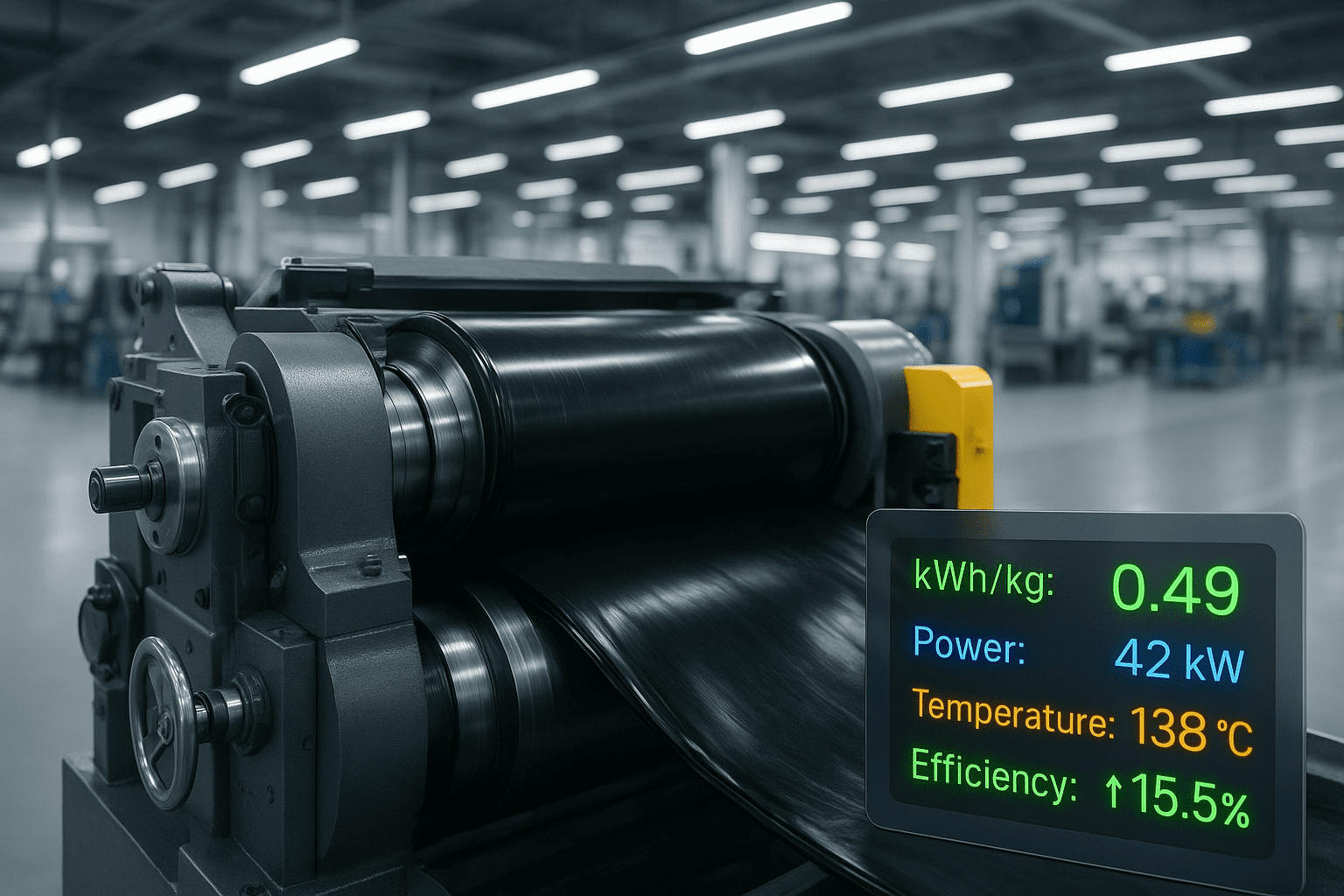

Energy costs are a big concern for rubber manufacturers. New energy-efficient mixing mills use up to 30% less power than older machines. This saves money and helps the environment.

These mills achieve efficiency through better motor design. Variable speed drives adjust power based on mixing needs. When less force is needed, the motors use less electricity.

Heat recovery systems capture waste heat from mixing. This heat warms up cold materials or heats factory buildings. Nothing gets wasted.

Energy-Saving Features:

- Variable frequency drive motors

- Heat recovery systems

- Improved insulation

- Smart power management

- Automatic standby modes

Some mills also use regenerative braking. When the cylinders slow down, they generate electricity. This power goes back to the factory’s electrical system.

The payback time for these energy-efficient systems is usually 2-3 years. After that, companies save money every month on electricity bills.

Smart Mixing Mill Systems: Industry 4.0 Comes to Rubber

Smart mixing mill systems represent the future of rubber processing. These machines connect to factory networks and share data in real-time. Managers can monitor production from anywhere using smartphones or computers.

Internet of Things (IoT) sensors track everything. They measure vibration, temperature, pressure, and mixing speed. All this data goes to cloud computers for analysis.

Digital twin technology creates virtual copies of the mixing process. Engineers can test changes on the computer before trying them on real machines. This prevents costly mistakes and downtime.

Smart System Capabilities:

- Remote monitoring and control

- Predictive maintenance alerts

- Real-time quality analysis

- Automatic recipe adjustments

- Production optimization suggestions

Machine learning algorithms analyze patterns in the data. They can predict when parts will need replacement. This prevents unexpected breakdowns that stop production.

The systems also optimize mixing recipes automatically. If the rubber quality isn’t perfect, the computer adjusts temperature, pressure, or mixing time. This happens without stopping production.

https://en.mesnac.com/solutions/c1-1.html

Innovations in Rubber Compounding: Precision Meets Performance

Rubber compounding innovations focus on getting the exact mixture every time. New systems weigh ingredients to the nearest gram. This precision ensures consistent product properties.

Automated ingredient handling reduces contamination. Materials move through sealed systems from storage to mixing. This keeps dirt and moisture out of the rubber compound.

Multi-stage mixing allows for complex formulations. First, the system mixes basic ingredients. Then it adds sensitive chemicals that need special handling. Each stage has different temperature and pressure settings.

Advanced Compounding Features:

- Precision weighing systems

- Contamination-free material handling

- Multi-stage mixing processes

- Temperature-controlled storage

- Automatic quality testing

Some systems can handle over 50 different ingredients in one batch. Each ingredient gets added at exactly the right time and amount. This creates rubber compounds with very specific properties.

Quality control happens during mixing, not after. Sensors test the rubber’s properties as it mixes. If something is wrong, the system can add more ingredients to fix the problem.

https://www.showes.com/resources-downloads/case-studies/rubber-mixing-feeding-system/

Market Growth and Future Trends

The rubber mixing mill market is growing fast. The market size was valued at USD 0.165 Billion in 2023 and is expected to reach USD 0.33 Billion by 2031, growing at a 5.8% CAGR from 2024 to 2031.

This growth comes from several factors. The car industry needs more rubber for electric vehicle parts. Medical device manufacturing is expanding. Green building materials use more rubber compounds.

Key Market Drivers:

- Electric vehicle expansion

- Medical device growth

- Green construction materials

- Automation adoption

- Quality requirements

Artificial intelligence will play a bigger role in future systems. AI will optimize mixing recipes in real-time. It will predict maintenance needs months in advance. Voice commands might control mixing operations.

Sustainability will drive more innovations. New mills will recycle waste heat even better. They might use renewable energy sources like solar power. Biodegradable rubber compounds will need special mixing techniques.

https://www.marketresearchintellect.com/product/global-rubber-mixing-mill-market-size-and-forecast/

Benefits of Modern Mixing Technology

Modern rubber mixing mills offer many advantages over traditional systems. Companies see improvements in quality, efficiency, and profitability.

Quality improvements are the most noticeable benefit. Modern systems produce rubber with consistent properties. This reduces rejected products and customer complaints. Better quality also means higher selling prices.

Efficiency gains come from automation and optimization. Machines run faster and with less downtime. Workers can operate multiple machines at once. Production capacity increases without hiring more people.

Business Benefits:

- Higher product quality

- Increased production speed

- Lower labor costs

- Reduced waste

- Better safety records

Safety improvements protect workers and equipment. Sensors detect dangerous conditions and stop machines automatically. Emergency systems prevent accidents. Better working conditions help companies attract skilled workers.

Environmental benefits include lower energy use and less waste. Modern mills produce fewer emissions. They use materials more efficiently. This helps companies meet environmental regulations.

https://dataintelo.com/report/global-rubber-mixing-machine-market

Implementation Challenges and Solutions

Installing modern mixing systems isn’t always easy. Companies face several challenges when upgrading their equipment.

The biggest challenge is cost. New systems can cost millions of dollars. However, financing options and government incentives help. The long-term savings usually justify the investment.

Worker training is another challenge. Modern systems need skilled operators. Companies must invest in education and training programs. Some equipment suppliers offer training as part of their service.

Common Implementation Challenges:

- High initial investment costs

- Worker training requirements

- System integration complexity

- Downtime during installation

- Change management resistance

Integration with existing systems can be complex. New mills must work with current quality control and inventory systems. This often requires custom software development.

Planning helps overcome these challenges. Companies should start with pilot projects. They can test new technology on a small scale first. Success with pilot projects builds confidence for larger investments.

https://formulatedmaterials.com/smart-batch/

Real-World Applications and Case Studies

Many companies are already using modern mixing technology successfully. Their experiences show what works and what doesn’t.

A tire manufacturer in Germany installed AI-powered mixing systems. HF Mixing Group has developed an AI-based algorithm, called Smart Final Mix, for optimising final mixing processes in the tire and technical rubber goods industries. The system reduced mixing time by 15% while improving quality consistency.

Medical device companies benefit from precision mixing. One company making surgical gloves upgraded to automated systems. They reduced defect rates by 60%. Product recalls became almost zero.

Success Story Examples:

- Tire manufacturer: 15% faster mixing, better quality

- Medical device company: 60% fewer defects

- Industrial seal manufacturer: 25% energy savings

- Automotive parts company: 40% less waste

Automotive parts manufacturers see major improvements in efficiency. One company making rubber seals installed smart monitoring systems. They caught quality problems before products shipped. Customer satisfaction scores improved significantly.

The key to success is proper planning and gradual implementation. Companies that rushed installations faced more problems. Those that took time to train workers and test systems had better results.

https://www.european-rubber-journal.com/article/2094969/hf-mixing-tool-final-mixing-processes

The Role of Digital Twins in Rubber Processing

Digital twin technology is becoming crucial for rubber mixing operations. Digital Twin is a virtual representation of objects, processes, and systems that exist in real-time. This technology creates exact computer models of mixing processes.

Engineers use digital twins to test changes without stopping production. They can try different mixing speeds, temperatures, or ingredient amounts. The computer shows what would happen in real life.

This testing prevents costly mistakes. If a change would damage equipment or reduce quality, the digital twin shows this before trying it on real machines.

Digital Twin Applications:

- Process optimization testing

- Maintenance planning

- Operator training simulations

- Quality prediction modeling

- Equipment design improvements

Digital twins also help train new workers. Operators can practice on the computer model before working with real machines. This reduces training time and prevents accidents.

The technology improves maintenance planning too. The digital twin predicts when parts will wear out. Maintenance teams can order replacement parts early and schedule repairs during planned downtime.

https://www.wizata.com/knowledge-base/applications-and-benefits-of-digital-twin-for-industry-4.0

IoT Sensors and Smart Monitoring

Internet of Things sensors make rubber mixing mills much smarter. These sensors, attached to physical assets, continuously collect data about their state, performance, and environment. Whether it’s the temperature of a machine, the speed of a conveyor belt, or the humidity in a production facility, these sensors capture it all.

Different sensors monitor different aspects of mixing. Temperature sensors prevent overheating. Pressure sensors ensure consistent force application. Vibration sensors detect bearing problems before they cause breakdowns.

All sensor data goes to central computer systems. Software analyzes this information and sends alerts when something needs attention. Managers get messages on their phones if problems occur.

Key Sensor Types:

- Temperature monitoring sensors

- Pressure measurement devices

- Vibration analysis sensors

- Speed monitoring systems

- Quality measurement sensors

The data also helps optimize production. Computers analyze patterns to find the best mixing settings. They might discover that slightly lower temperatures produce better results. These insights improve quality and reduce costs.

Some advanced sensors can even measure rubber properties during mixing. They check thickness, hardness, and chemical composition. This real-time testing ensures every batch meets specifications.

https://www.toobler.com/blog/industry-4-0-and-digital-twin

Predictive Maintenance Revolution

Predictive maintenance is changing how companies care for their mixing equipment. Instead of fixing things after they break, modern systems predict problems before they happen.

Digital Twin technology uses IoT sensors to generate real-time data and identify problems within the system. Manufacturers can use the real-world data to run future simulations and pinpoint the exact moment when a machine will break down.

This approach saves money and prevents production delays. Emergency repairs cost much more than planned maintenance. Unexpected breakdowns can stop entire production lines.

The system tracks patterns in equipment behavior. When a bearing starts to fail, vibration patterns change slightly. The computer notices these changes weeks before humans would see problems.

Predictive Maintenance Benefits:

- Reduced emergency repair costs

- Eliminated unexpected downtime

- Extended equipment life

- Improved safety

- Better maintenance planning

Maintenance teams get detailed repair schedules months in advance. They can order parts early and plan work during slow production periods. This keeps machines running when production demand is high.

Some systems even suggest the best maintenance techniques. They might recommend specific lubricants or replacement procedures based on operating conditions.

https://www.identecsolutions.com/news/tire-manufacturing-smart-processes-to-conserve-rubber

Environmental Impact and Sustainability

Modern rubber mixing mills are much better for the environment. They use less energy, produce less waste, and reduce harmful emissions.

Energy efficiency improvements are significant. New mills use variable speed motors that adjust power consumption based on mixing needs. When less force is required, motors automatically reduce power usage.

Waste reduction comes from better process control. Precise ingredient measurement reduces off-specification batches. Automated quality control catches problems early, before materials are wasted.

Environmental Benefits:

- 30% lower energy consumption

- 50% less material waste

- Reduced air emissions

- Lower water usage

- Recyclable equipment components

Heat recovery systems capture waste energy from mixing processes. This heat can warm buildings or preheat cold materials. Nothing gets wasted.

Some new systems can even process recycled rubber materials. They can break down old tires or rubber products and mix them into new compounds. This reduces the need for new raw materials.

Companies using these systems often qualify for environmental certifications. This helps them win contracts with environmentally conscious customers. Green building standards increasingly require sustainable materials.

Future Innovations on the Horizon

The rubber mixing industry continues to evolve rapidly. Several exciting innovations are coming soon.

Artificial intelligence will become even more sophisticated. Future systems might design new rubber compounds automatically. They could optimize formulations for specific applications without human input.

Nanotechnology will enable new mixing techniques. Tiny particles can be distributed more evenly through rubber compounds. This creates materials with amazing new properties.

Emerging Technologies:

- Advanced AI recipe optimization

- Nanotechnology integration

- 3D printing of mixing components

- Blockchain quality tracking

- Augmented reality maintenance

Blockchain technology might track ingredients from source to finished product. This would ensure quality and prevent counterfeit materials from entering the supply chain.

Augmented reality could help maintenance workers. Smart glasses might show repair instructions overlaid on actual equipment. This would speed up repairs and reduce errors.

3D printing might create custom mixing components on demand. Instead of waiting weeks for replacement parts, companies could print them in hours.

Investment Considerations and ROI

Companies considering modern mixing technology need to understand the costs and benefits. The initial investment is significant, but returns can be substantial.

The global rubber mixing machine market size was valued at USD 1.5 billion in 2023 and is projected to reach approximately USD 2.5 billion by 2032, growing at a compound annual growth rate (CAGR) of 5.5% during the forecast period.

Typical payback periods range from 2-4 years depending on the system and application. Energy savings alone often justify 20-30% of the investment cost.

Quality improvements provide additional returns. Reduced defect rates save money on wasted materials and rework. Better consistency can command premium prices from customers.

ROI Factors:

- Energy cost savings (20-30% reduction)

- Labor cost reductions (fewer operators needed)

- Quality improvements (higher selling prices)

- Reduced waste (material cost savings)

- Increased production capacity

Maintenance cost reductions are also significant. Predictive maintenance prevents expensive emergency repairs. Extended equipment life delays replacement investments.

Companies should consider government incentives too. Many regions offer tax credits or grants for energy-efficient manufacturing equipment. These programs can reduce the net investment significantly.

Choosing the Right System for Your Needs

Selecting the best mixing system requires careful analysis of specific needs. Different applications need different features.

High-volume producers need maximum automation and efficiency. They benefit most from smart monitoring and predictive maintenance. The higher initial cost is justified by large-scale savings.

Specialty rubber producers need flexibility and precision. They might prioritize multi-stage mixing and precise ingredient control over maximum speed.

Selection Criteria:

- Production volume requirements

- Product quality specifications

- Available floor space

- Budget constraints

- Technical expertise available

Small companies might start with basic automated systems. They can add smart features later as they grow. Modular designs allow for gradual upgrades.

Technical support is crucial. Choose suppliers who offer comprehensive training and service. Local support reduces downtime when problems occur.

Consider future needs too. Systems should be expandable and upgradeable. Today’s cutting-edge technology becomes standard equipment in just a few years.

Training and Workforce Development

Modern mixing systems require skilled operators. Companies must invest in training to get full benefits from new technology.

Basic operator training covers system controls and safety procedures. Workers learn to monitor displays and respond to alarms. This training usually takes 1-2 weeks.

Advanced training covers troubleshooting and optimization. Skilled operators can adjust parameters to improve quality or efficiency. This level of expertise takes months to develop.

Training Program Elements:

- Basic operation and safety

- Advanced troubleshooting skills

- Quality control procedures

- Maintenance basics

- Computer system navigation

Some equipment suppliers offer training programs. These programs combine classroom instruction with hands-on practice. Certification programs validate operator skills.

Cross-training helps companies handle staffing changes. Multiple workers should understand each system. This prevents production delays when key people are unavailable.

Ongoing education keeps skills current. Technology continues evolving rapidly. Regular training updates ensure operators use all available features effectively.

Conclusion: The Future is Smart and Sustainable

Modern rubber mixing mills represent a major advance in manufacturing technology. They combine automation, artificial intelligence, and environmental responsibility in powerful ways.

Companies investing in these systems see immediate benefits. Better quality, higher efficiency, and lower costs improve competitiveness. Long-term advantages include reduced environmental impact and enhanced worker safety.

The technology will continue advancing rapidly. Artificial intelligence will become more sophisticated. Environmental benefits will increase. New applications will emerge as costs decrease.

Key Takeaways:

- Smart technology transforms rubber mixing

- Automation improves quality and efficiency

- Environmental benefits are substantial

- ROI justifies the investment

- Proper training is essential for success

Success requires careful planning and implementation. Companies should start with clear goals and realistic timelines. Proper training and technical support are essential.

The rubber industry is entering an exciting new era. Modern mixing mills are just the beginning. Smart, sustainable manufacturing will define the next decade of growth and innovation.

Companies that embrace these technologies today will lead their industries tomorrow. The question isn’t whether to adopt modern mixing technology, but how quickly to implement it.