Every morning at 6:45 AM, Rajesh Kumar walks into his rubber manufacturing plant in Pune. Before the production line starts humming, he’s already halfway through his hydraulic press maintenance checklist. It’s a routine that’s saved his company from countless breakdowns and keeps his three presses running at 98% uptime.

“Five years ago, we were losing two days a month to press failures,” Rajesh tells us. “Now? Maybe two hours a year. The difference? A proper hydraulic press maintenance checklist that we actually follow.”

If you’re reading this, you know the pain of unexpected downtime. A single press failure can halt production, delay orders, and cost thousands. However, here’s what we’ve learned after manufacturing rubber hydraulic presses for over two decades at Vikas Industries: most press failures are completely preventable with the right maintenance routine.

Why Hydraulic Press Preventive Maintenance Matters

Your hydraulic press is a workhorse, but it’s not invincible. Without systematic press preventive maintenance, small issues snowball into major failures. Consider these real numbers from our service records:

- Regular maintenance reduces breakdowns by 70%

- Extends press life from 10 years to 15+ years

- Cuts emergency repair costs by 60%

- Maintains consistent product quality

- Improves operator safety significantly

The Occupational Safety and Health Administration (OSHA) emphasizes that regular equipment maintenance isn’t just good practice—it’s essential for workplace safety. Moreover, proper maintenance protects your investment and ensures compliance with industry standards.

Let’s walk through exactly what a proper hydraulic press maintenance checklist looks like, following Rajesh through his actual daily, weekly, and monthly routines.

A Day in the Life: Morning Press Rounds (6:45 AM – 7:30 AM)

Rajesh starts every shift the same way. Coffee in hand, tablet loaded with his digital checklist, he begins his rounds. Here’s his exact routine that keeps his Vikas Industries hydraulic presses running smoothly.

Daily Hydraulic Press Maintenance Checklist

Visual Inspection (10 minutes per press)

Check hydraulic oil level

- First, look at sight glass on reservoir

- Oil should be between MIN and MAX marks

- If low, investigate for leaks before topping up

- Rajesh’s tip: “I check this first because low oil means trouble is coming”

Inspect for oil leaks

- Initially, walk around entire press perimeter

- Next, check floor under hydraulic unit

- Then, examine all hose connections and fittings

- Additionally, look for oil mist or wetness on cylinders

- Common leak spots: ram seals, valve blocks, quick couplers

Examine hydraulic hoses and connections

- Look for cracks, bulges, or wear on hose exteriors

- Subsequently, check for loose fittings (hand-tight test)

- Verify hose routing—no sharp bends or abrasion points

- Finally, replace any hose showing outer wire braid

Verify pressure gauge readings

- Operating pressure should match specifications (typically 150-250 bar)

- Furthermore, gauge needle shouldn’t flutter (indicates pump issues)

- Record readings in maintenance log

- For our rubber processing equipment, standard pressure is 200 bar ±10

Safety Systems Check for Hydraulic Press Maintenance

Test emergency stop function

- Press E-stop button

- Consequently, verify complete power shutdown

- Release and confirm normal restart

- This takes 30 seconds but could save a life

Listen for unusual noises

- Hydraulic pump whining (indicates cavitation)

- Grinding sounds (bearing wear)

- Hissing (air in system or leaks)

- Clicking valves (contamination or wear)

- Rajesh says: “After two years, you know your press’s normal sound. Anything different needs investigation.”

Equipment Condition Assessment

Check pressure relief valve operation

- Should activate at set pressure (usually 10% above working pressure)

- Listen for relief valve opening during pressure buildup

- No constant relief means valve is functioning correctly

Inspect platens and tooling

- Look for cracks, deformation, or wear

- Check parallelism (use feeler gauges)

- Clean off rubber residue or contamination

- Verify mounting bolts are tight

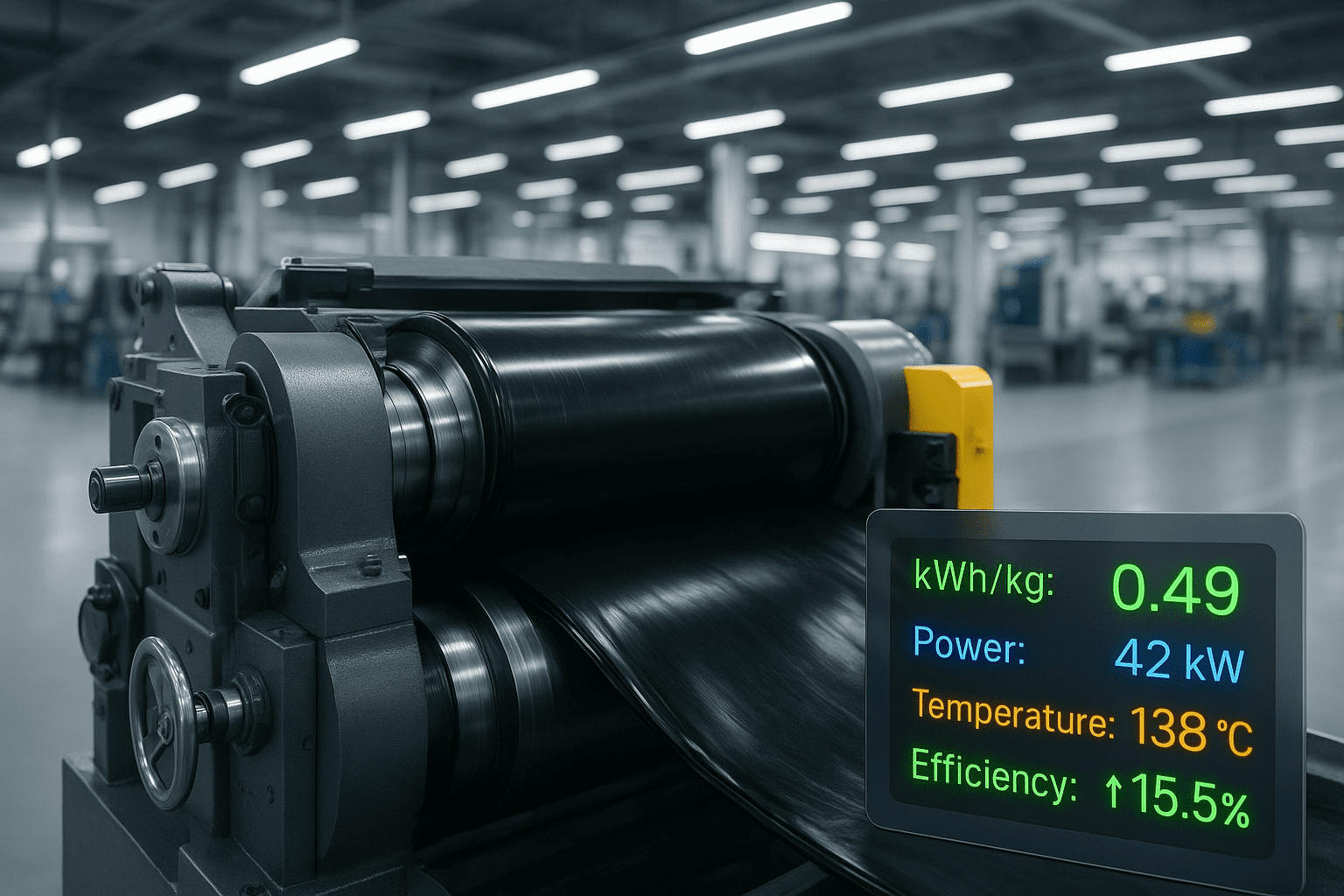

Verify temperature readings

- Hydraulic oil temperature: 40-60°C optimal, max 80°C

- If over 65°C, check cooling system immediately

- Motor bearing temperature: should be warm, not hot to touch

Daily Lubrication Points (5 minutes)

Grease slide mechanisms

- Apply lithium-based grease to guide columns

- Wipe excess to prevent dirt accumulation

- 2-3 pumps per grease point

Lubricate moving parts

- Pivot points on safety gates

- Adjustable bolsters and guides

- Any exposed sliding surfaces

Documentation (5 minutes)

Rajesh enters all findings into his tablet:

- Oil level reading

- Pressure gauge values

- Any abnormalities noted

- Actions taken

- Next inspection due date

“The log saved us once,” he recalls. “We noticed pressure slowly dropping over three weeks. Consequently, we found a tiny seal leak before it became catastrophic.”

Total daily routine time: 20 minutes per press

By 7:30 AM, Rajesh has checked all three presses, logged everything, and production can start confidently.

Wednesday Deep Check: Weekly Hydraulic Press Maintenance (45 minutes)

Every Wednesday afternoon during lunch break, Rajesh conducts his weekly hydraulic press preventive maintenance. This goes deeper than daily checks and helps extend press life significantly.

Weekly Hydraulic Press Preventive Maintenance Tasks

Oil and Filter Management

Hydraulic oil condition check

- Draw small sample from drain valve

- Visual check: should be amber/clear, not dark or milky

- Proper hydraulic fluid maintenance is critical for system longevity

- Milky oil = water contamination (check coolers)

- Dark oil = oxidation or contamination

- Metallic particles = wear (send for lab analysis)

Filter inspection and cleaning

- Check return filter indicator

- If red/yellow, replace filter element immediately

- Clean suction strainer in reservoir

- Log filter condition and replacement dates

- Rajesh uses genuine replacement filters for his rubber processing machinery

Performance Testing

Pressure testing under load

- Run press through complete cycle

- Monitor pressure during each phase (advance, dwell, return)

- Pressure should remain steady during dwell

- Pressure drop indicates internal leakage

Inspect electrical connections

- Check all terminal tightness

- Look for discoloration (indicates heating)

- Verify wire insulation condition

- Test control buttons and switches

- Confirm indicator lights function

Safety and Alignment Checks

Safety system verification

- Test light curtains (if equipped)

- Verify two-hand control operation

- Check safety gate interlocks

- Test pressure-sensitive mats

- Ensure safety labels are visible and intact

Ram alignment check

- Use dial indicator or straightedge

- Maximum allowable deviation: 0.1mm per meter

- Misalignment causes uneven wear and seal damage

- Adjust if necessary using alignment procedures

System Components

Cooling system inspection

- Check coolant level in heat exchanger

- Verify fan operation (if air-cooled)

- Clean heat exchanger fins

- Check for leaks in cooling lines

Inspect foundation and mounting

- Look for cracks in base or mounting pad

- Check anchor bolt tightness

- Verify level (use precision level)

- Floor cracks indicate alignment issues

Review maintenance log

- Analyze trends from daily checks

- Note any recurring issues

- Plan corrective actions

- Update preventive maintenance schedule

Total weekly routine time: 45 minutes per press

First of the Month: Monthly Comprehensive Inspection (2-3 hours)

On the first Monday of each month, Rajesh schedules a thorough inspection. Production gives him a 3-hour window to extend press life through comprehensive preventive maintenance.

Monthly Hydraulic Press Maintenance Checklist

Complete hydraulic system analysis

Measure actual flow rate

- Compare to specifications

- Check accumulator pre-charge pressure (if equipped)

- Test all directional control valves

- Verify proportional valve response (if applicable)

- Inspect and clean hydraulic reservoir interior

Oil sampling and laboratory analysis

Send oil sample to testing lab

- Check for: viscosity, contamination, metal particles, water content

- Compare results to baseline

- Oil analysis predicts failures 6-8 weeks in advance

- According to tribology experts, oil analysis is the most cost-effective predictive maintenance tool

Ram and seal comprehensive inspection

Extend ram fully for inspection

- Inspect chrome plating for scoring or wear

- Check seal condition (no visible damage)

- Measure ram for straightness

- Replace seals if any seepage detected

- Clean and inspect rod wipers

Valve block service

Disassembly and cleaning (every 6 months, or monthly in dirty environments)

- Remove and disassemble control valves

- Clean all components with solvent

- Inspect spools for wear or scoring

- Replace worn O-rings

- Reassemble with proper torque specifications

Electrical system comprehensive check

Motor and control testing

- Megohm test on motor windings

- Inspect motor bearings (listen with stethoscope)

- Check all relay contacts

- Test overload protection settings

- Verify PLC battery backup (if applicable)

- Review and clear any fault logs

Pressure relief valve testing

Set up pressure test gauge

- Slowly increase pressure to relief setting

- Verify opens at correct pressure (±5%)

- Should close when pressure drops 10-15%

- Clean and reseat if not functioning properly

Platen parallelism precision measurement

Use dial indicators at four corners

- Maximum variation: 0.05mm

- Critical for even pressure distribution

- Adjust using shims or leveling screws

- Document measurements

Hydraulic cylinder internal inspection

Annual or every 3 months for heavy-duty applications

- Check for internal scoring

- Measure piston seal wear

- Inspect piston rod threads

- Replace worn components

- Re-torque all fasteners

Complete lubrication service

Grease all bearings to manufacturer specs

- Lubricate all pivot points

- Check gear reducers oil level (if applicable)

- Apply anti-seize to threaded adjustments

Safety device calibration

Test force limiters with calibrated load cell

- Verify safety valve settings

- Calibrate pressure transducers

- Test emergency descent system

Documentation update

Update maintenance history

- Order replacement parts for upcoming service

- Schedule next major service

- Review and update SOPs if needed

- Train any new operators on findings

Total monthly routine time: 2-3 hours per press

Rajesh’s Pro Tips for Extending Press Life

After five years of diligent maintenance, Rajesh has learned shortcuts and critical points that make his hydraulic press maintenance checklist more effective.

The Three Things That Kill Presses Fastest

Contaminated hydraulic oil “Change filters religiously. One $50 filter saves a $5,000 pump.”

Ignored small leaks “A drip today is a puddle next month and a breakdown next quarter.”

Skipped inspections “Miss one week, nothing happens. Miss three months, you’re buying parts.”

Money-Saving Insights

Keep detailed logs “Our maintenance history helped us negotiate 30% off insurance premiums”

Buy quality parts “Cheap seals last 6 months. OEM seals last 3 years. Do the math.”

Train everyone “When operators know what to listen for, they catch problems early”

Essential Spare Parts to Keep On Hand

Smart maintenance means being prepared. Rajesh keeps these in his maintenance room for his Vikas Industries equipment:

Critical Spares for Press Preventive Maintenance

- Complete seal kits (ram and cylinder)

- Set of hydraulic hoses (common lengths)

- Hydraulic filters (return and pressure)

- Pressure gauge

- Solenoid valve coils

- Relay set

- Emergency stop buttons

- Basic O-ring kit

Tools Required for Hydraulic Press Maintenance Checklist

- Torque wrench set

- Hydraulic pressure test kit

- Feeler gauges

- Dial indicator

- Oil sampling equipment

- Infrared thermometer

- Ultrasonic leak detector (optional but valuable)

When to Call Professional Service

Even with perfect maintenance, some jobs require experts. Specifically, these situations need professional attention:

- Hydraulic pump replacement or rebuild

- Major cylinder repairs

- Control system reprogramming

- Structural repairs or modifications

- Annual certification inspections

- Pressure vessel inspections (legal requirement)

At Vikas Industries, our service team provides comprehensive support for all rubber hydraulic presses. Specifically, we offer:

- 24/7 emergency support across India

- Scheduled preventive maintenance contracts

- Operator training programs

- Genuine spare parts with same-day dispatch

- Remote diagnostics and troubleshooting

Hydraulic Press Maintenance Schedule Summary

Print this and post it at your press:

| Frequency | Duration | Key Tasks |

|---|---|---|

| Daily | 20 min | Visual inspection, oil level, leaks, pressure check, lubrication |

| Weekly | 45 min | Oil condition, filters, electrical, safety systems, alignment |

| Monthly | 2-3 hrs | Complete system analysis, oil sampling, seal inspection, valve service |

| Quarterly | 4 hrs | Deep cleaning, calibration, comprehensive testing |

| Annually | 8 hrs | Cylinder overhaul, complete system certification, major component replacement |

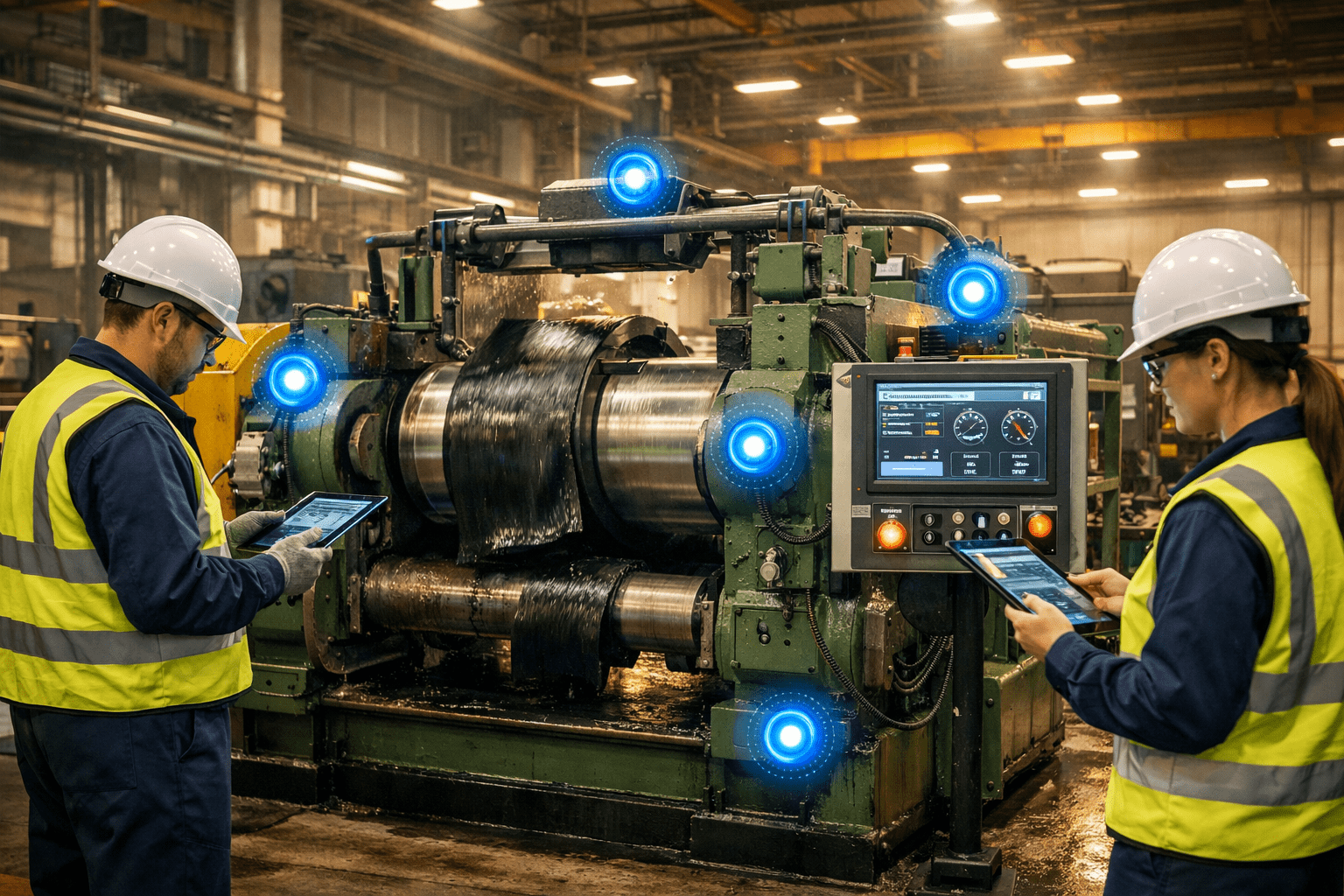

Digital Maintenance Tracking

Rajesh upgraded from paper logs to a digital system last year. His recommendations:

- Use simple spreadsheet or maintenance app

- Take photos of issues (visual records are invaluable)

- Set automatic reminders

- Track costs per press (identifies problem machines)

- Share logs with operators for awareness

ROI of Proper Hydraulic Press Preventive Maintenance

Rajesh’s plant data over 5 years demonstrates the value of following a hydraulic press maintenance checklist:

- Maintenance cost per year: ₹1,20,000 (for 3 presses)

- Emergency repairs avoided: ₹8,50,000

- Production downtime prevented: 180 hours (worth ₹12,00,000)

- Extended equipment life: 5 additional years (depreciation savings: ₹15,00,000)

Total 5-year ROI: 2,850%

“The numbers don’t lie,” Rajesh says. “Maintenance isn’t a cost—it’s an investment that pays for itself ten times over.”

Upgrading to Modern Hydraulic Press Technology

If your press is over 15 years old and constantly needs repairs, consider upgrading. Modern Vikas Industries hydraulic presses feature:

- Advanced monitoring systems – Real-time pressure, temperature, and cycle tracking

- Predictive maintenance alerts – System warns before failures occur

- Energy-efficient designs – 30-40% lower power consumption

- Improved safety systems – Latest international safety standards

- Easier maintenance access – Modular designs for faster service

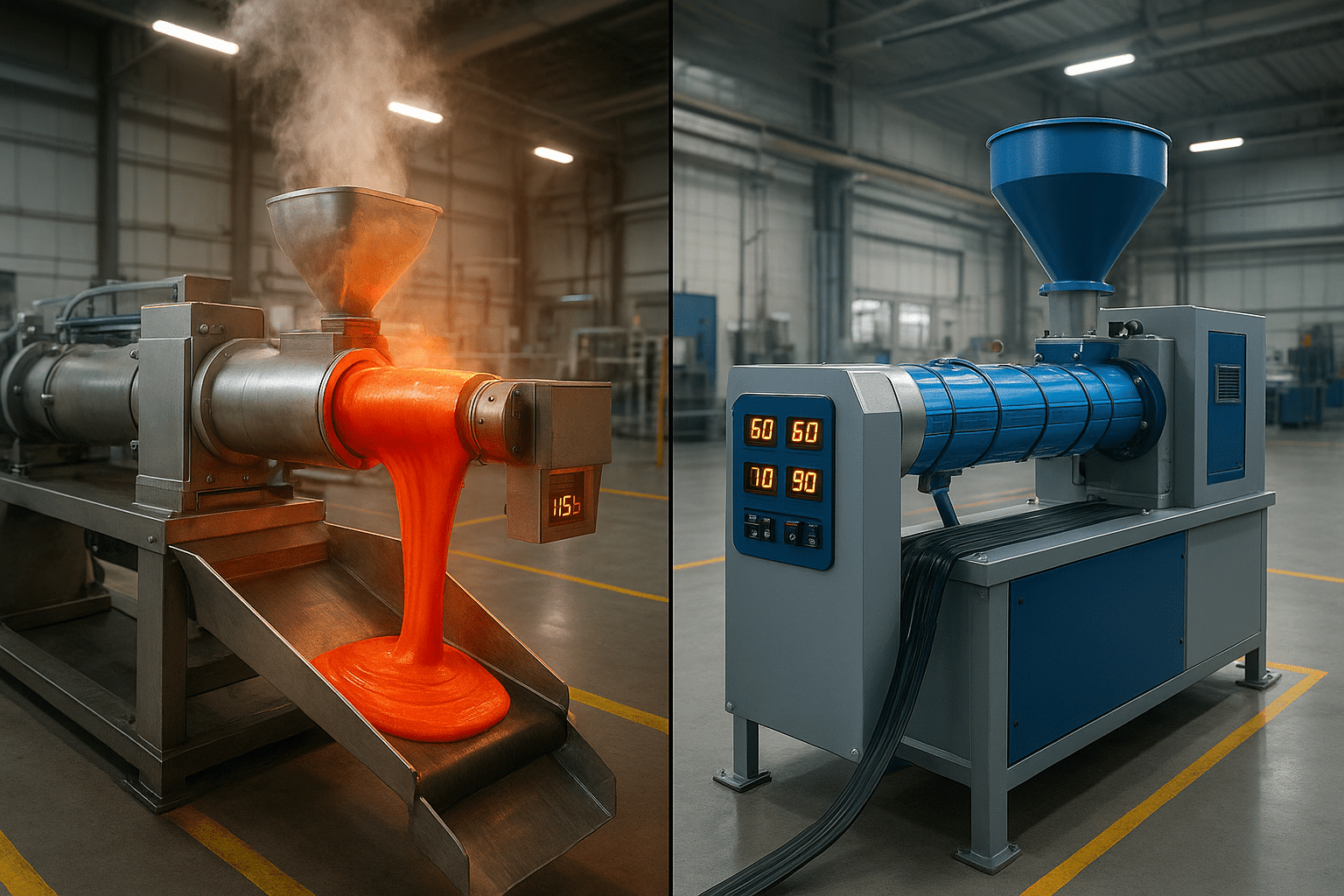

Our complete rubber processing line includes Rubber Mixing Mills, Dispersion Kneaders, Rubber Bale Cutters, and Hot & Cold Feed Extruders for integrated production solutions.

Your Action Plan: Getting Started Today

Week 1: Assessment

- Evaluate current maintenance practices

- Review equipment manuals

- Create baseline inspection checklist

- Take photos of current condition

Week 2: Implementation

- Assign responsibility (who does what)

- Order necessary tools and spare parts

- Set up maintenance log system

- Schedule first comprehensive inspection

Week 3: Training

- Train operators on daily checks

- Review safety procedures

- Practice emergency shutdown

- Establish communication protocols

Week 4: Optimization

- Review first month’s data

- Adjust schedule based on findings

- Order additional supplies as needed

- Celebrate wins with the team

Need Expert Guidance for Your Hydraulic Press Maintenance Checklist?

Setting up a hydraulic press maintenance checklist can seem overwhelming. At Vikas Industries, we help companies like yours maximize uptime and extend press life through:

- Free consultation on maintenance best practices

- Customized maintenance schedules for your specific equipment

- On-site training for your maintenance team

- Comprehensive service contracts

- Genuine parts supply with technical support

Get Your Free Press Maintenance Consultation →

Conclusion

Rajesh’s story isn’t unique—it’s repeatable. A solid hydraulic press maintenance checklist combined with consistent execution transforms press reliability. The difference between 60% uptime and 98% uptime isn’t luck or newer equipment—it’s discipline.

Start with daily checks. Add weekly inspections. Build toward monthly comprehensive service. Track everything. Learn from your data.

Your hydraulic press is ready to run for 15-20 years without major issues. The question is: are you ready to maintain it properly?

Remember: The best hydraulic press preventive maintenance program is the one you actually follow. Start simple, be consistent, and build from there.

Ready to implement a world-class maintenance program? Contact Vikas Industries today for expert support.

Frequently Asked Questions About Hydraulic Press Maintenance

Q: How often should I change hydraulic oil in my press?

A: Typically every 2,000 operating hours or annually, whichever comes first. However, oil analysis every 6 months determines actual condition. Clean systems can go 3,000+ hours, while contaminated systems may need changes every 1,000 hours. Monitor oil color and test results rather than following fixed intervals blindly for effective hydraulic press maintenance.

Q: What causes most hydraulic press failures?

A: Contaminated hydraulic oil causes 70-80% of all hydraulic system failures. Dirt particles damage seals, valves, and pumps. Second is poor maintenance—ignoring small leaks and skipping inspections. Third is operator error—overloading or improper use. All three are completely preventable with proper hydraulic press preventive maintenance and following your maintenance checklist consistently.

Q: How do I know when hydraulic seals need replacement?

A: Warning signs include visible oil seepage around ram, pressure drops during dwell cycle, slower cycle times, or visible damage to seal surfaces. Replace seals at first sign of leakage—small drips become major leaks quickly. Most seals last 2-3 years with proper maintenance, but inspect monthly and replace proactively every 3-4 years as part of your hydraulic press maintenance checklist.

Q: Can I use any hydraulic oil in my press?

A: No—use only the viscosity grade specified by manufacturer (usually ISO 32 or 46 for rubber presses). Wrong viscosity causes pump damage, excessive heat, or sluggish operation. Always use quality hydraulic oil meeting ISO cleanliness standards. Mixing different brands reduces performance. Stick to manufacturer recommendations for optimal press preventive maintenance.

Q: What’s the most important item on a hydraulic press maintenance checklist?

A: Daily oil level and leak checks are most critical. Low oil damages pumps within minutes. Small leaks indicate seal failure and contamination entry points. This 2-minute daily check prevents 90% of catastrophic failures. Second most important is maintaining proper oil cleanliness through regular filter changes as part of your hydraulic press preventive maintenance routine.

Q: How much does preventive maintenance cost compared to reactive repairs?

A: Preventive maintenance typically costs ₹40,000-60,000 annually per press (including labor, parts, and oil). In contrast, a major breakdown costs ₹2,00,000-5,00,000 plus production losses of ₹50,000-2,00,000 per day. Organizations report 3:1 to 10:1 ROI on preventive maintenance. Every rupee spent on prevention saves ₹3-10 in emergency repairs, making a hydraulic press maintenance checklist essential.

This guide is based on real maintenance practices from Vikas Industries’ customer facilities and our 20+ years manufacturing rubber processing equipment. For customized maintenance support for your specific press model, contact our technical team for personalized consultation.