Setting up a rubber processing plant requires careful planning, significant investment, and deep understanding of manufacturing processes. A well-planned rubber processing plant can generate substantial profits while serving diverse industrial markets.

This comprehensive guide covers everything you need to know about how to set up a rubber processing plant. From initial planning to equipment selection, we’ll walk you through each critical step for establishing a successful rubber manufacturing facility.

Whether you’re an entrepreneur or expanding existing operations, this guide provides actionable insights for launching your rubber processing venture.

Planning Your Rubber Processing Plant Setup

Planning forms the foundation of any successful rubber processing plant. Thorough planning prevents costly mistakes and ensures smooth operations from day one.

Your rubber processing plant setup begins with market research and business planning. Understanding your target market, competition, and financial requirements guides all subsequent decisions.

Market Research and Analysis

Target Market Identification Identify specific industries and customers for your rubber products. Common markets include:

- Automotive industry (seals, gaskets, hoses)

- Construction sector (waterproofing, insulation)

- Industrial applications (conveyor belts, machinery parts)

- Consumer goods (footwear, household items)

- Medical industry (gloves, tubing, seals)

Research market size, growth trends, and pricing structures for each segment. This information helps determine plant capacity and product focus.

Competition Analysis Study existing rubber manufacturers in your region. Analyze their product ranges, pricing strategies, and market positioning. Identify gaps in the market where your plant can compete effectively.

Demand Forecasting Project future demand for rubber products in your target markets. Consider economic factors, industry trends, and seasonal variations that affect demand patterns.

Business Planning Essentials

Business Model Development Choose between different business models:

- Original Equipment Manufacturer (OEM) supplier

- Contract manufacturing for other brands

- Private label production

- Direct consumer sales

- Combination approach

Each model requires different capabilities and investment levels.

Financial Planning and Budgeting Develop comprehensive financial projections including:

- Initial capital requirements

- Operating expense estimates

- Revenue projections

- Break-even analysis

- Return on investment calculations

Accurate financial planning ensures adequate funding and realistic expectations.

Legal Structure Selection Choose appropriate business structure considering tax implications, liability protection, and growth plans. Consult legal and financial advisors for guidance.

Rubber Processing Plant Cost Analysis

Understanding rubber processing plant costs helps secure adequate financing and plan realistic budgets. Total investment varies significantly based on plant size, product types, and automation levels.

Typical rubber processing plant costs range from $100,000 for small operations to several million dollars for large industrial facilities. Breaking down costs helps prioritize spending and identify cost-saving opportunities.

Initial Capital Investment Breakdown

Land and Building Expenses Land costs vary by location but typically represent 15-25% of total investment. Consider factors like:

- Proximity to raw material suppliers

- Access to transportation networks

- Labor availability and costs

- Utility infrastructure availability

- Environmental regulations and permits

Building construction or lease costs depend on facility size and specifications. Industrial buildings require proper ventilation, electrical capacity, and safety features.

Equipment and Machinery Costs Machinery represents the largest expense category, often 40-60% of total investment. Equipment costs vary by:

- Production capacity requirements

- Automation level desired

- New versus used equipment selection

- Supplier choice and financing terms

Plan for additional equipment needs like material handling systems, quality control instruments, and maintenance tools.

Working Capital Requirements Working capital covers operational expenses until revenue begins. Typical requirements include:

- Raw material inventory (2-3 months supply)

- Finished goods inventory

- Accounts receivable financing

- Operating expense reserves (3-6 months)

- Emergency fund for unexpected costs

Ongoing Operational Costs

Raw Material Expenses Raw materials typically represent 40-60% of production costs. Major cost components include:

- Natural rubber or synthetic rubber polymers

- Chemical additives and accelerators

- Carbon black and fillers

- Processing oils and lubricants

- Packaging materials

Establish reliable supplier relationships and consider long-term contracts to manage cost volatility.

Labor and Staffing Costs Staffing levels depend on automation degree and production complexity. Typical positions include:

- Production operators and technicians

- Quality control personnel

- Maintenance staff

- Supervisory and management roles

- Administrative support staff

Factor in training costs, benefits, and potential wage increases over time.

Utility and Operating Expenses Ongoing expenses include:

- Electricity for equipment operation

- Natural gas or fuel oil for heating

- Water for cooling and cleaning

- Waste disposal and treatment

- Insurance premiums

- Maintenance and repair costs

Machinery Required for Rubber Product Manufacturing

Selecting appropriate machinery forms the core of successful rubber product manufacturing. The right equipment combination ensures product quality, production efficiency, and cost-effectiveness.

Machinery requirements vary significantly based on intended products, production volumes, and quality standards. Understanding different equipment types helps make informed purchasing decisions.

Essential Processing Equipment

Mixing and Compounding Machinery Mixing equipment combines raw rubber with additives to create uniform compounds. Key options include:

Internal Mixers Internal mixers provide excellent temperature control and consistent mixing results. They handle batch sizes from 5 liters to over 500 liters. Features to consider:

- Rotor design and speed control

- Temperature monitoring systems

- Automated material feeding

- Discharge mechanisms

- Safety interlocks and controls

Internal mixers work best for high-volume production with consistent compound recipes.

Two-Roll Mills Two-roll mills offer versatility for different compound types and batch sizes. They provide visual monitoring of mixing progress and easy compound removal. Consider:

- Roll diameter and working length

- Speed ratio and adjustment capabilities

- Cooling and heating systems

- Safety features and guards

- Maintenance accessibility

Mills excel for specialty compounds and smaller production runs.

Banbury Mixers Banbury mixers handle tough compounds and high-viscosity materials effectively. They provide intensive mixing action for challenging applications like carbon black dispersion.

Shaping and Forming Equipment

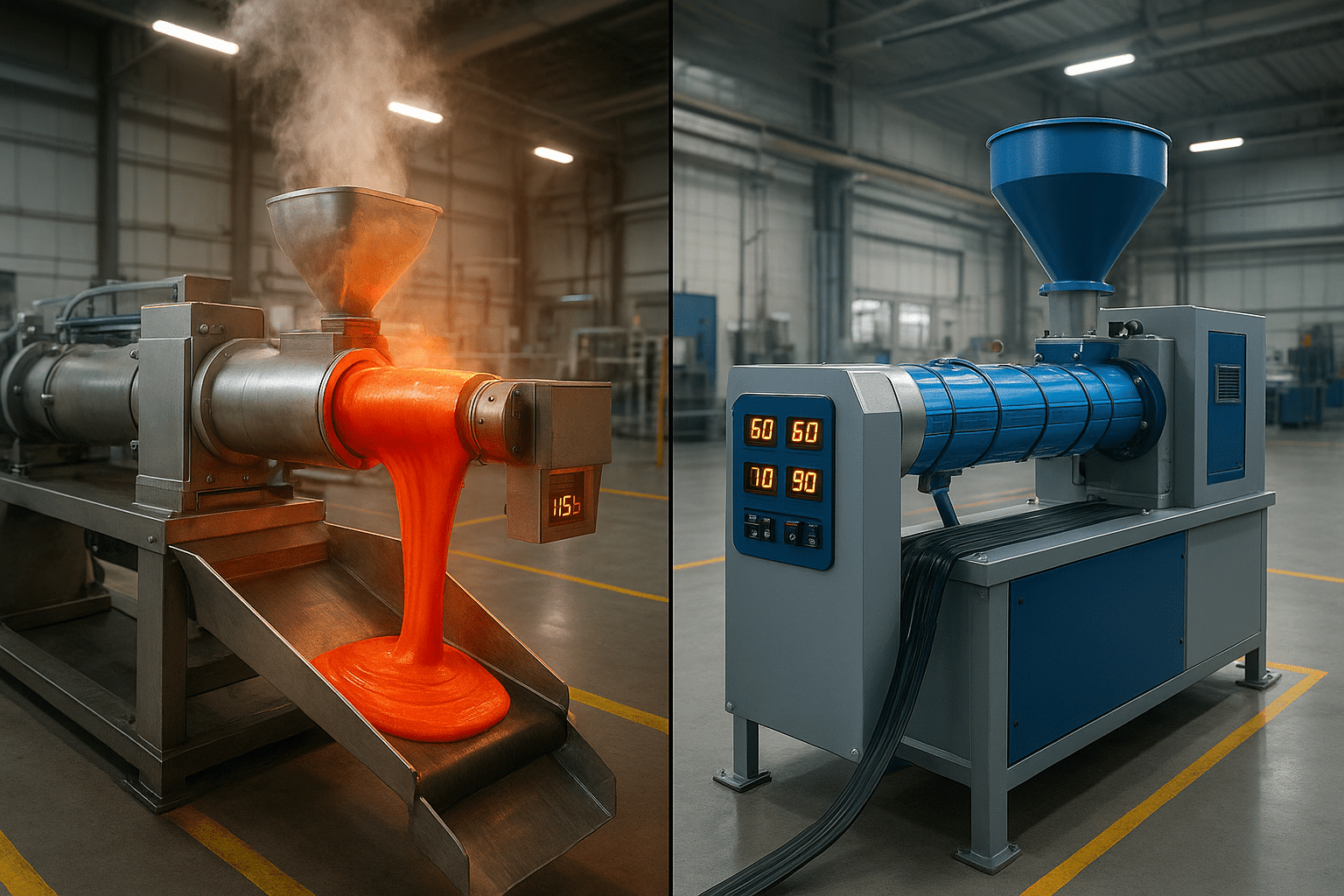

Extrusion Systems Extruders create continuous profiles like tubes, strips, and complex shapes. Modern extrusion systems include:

- Screw extruders for thermoplastic rubbers

- Ram extruders for conventional rubber compounds

- Co-extrusion systems for multi-layer products

- Downstream equipment for cooling and cutting

Consider production rates, profile complexity, and material compatibility when selecting extruders.

Compression Molding Presses Compression presses shape rubber products using heat and pressure in closed molds. Features include:

- Hydraulic or mechanical actuation

- Multi-daylight configurations

- Programmable control systems

- Quick mold change capabilities

- Safety systems and guards

Compression molding works well for complex shapes and thick products requiring precise dimensions.

Injection Molding Equipment Injection molding creates detailed parts with excellent surface finishes. Modern injection molding machines offer:

- Precise shot size control

- Multi-zone temperature control

- High-speed injection capabilities

- Automated part removal systems

- Integration with robotic systems

This process suits high-volume production of complex, thin-walled parts.

Calendering Lines Calendering equipment produces thin rubber sheets and coated fabrics. Complete lines include:

- Multi-roll calender stacks

- Fabric feeding systems

- Temperature control units

- Winding and cutting equipment

- Quality control systems

Calendering serves automotive, construction, and industrial markets requiring sheet products.

Curing and Vulcanization Equipment

Continuous Vulcanization (CV) Lines CV lines cure extruded profiles continuously using hot air or steam. Systems include:

- Heating chambers with precise temperature control

- Conveyor systems for product transport

- Cooling sections for temperature reduction

- Cutting and winding equipment

- Process control and monitoring

CV lines excel for high-volume production of cables, hoses, and profiles.

Batch Autoclaves Autoclaves cure multiple products simultaneously using steam heat and pressure. Consider:

- Chamber size and capacity

- Operating pressure and temperature ranges

- Loading and unloading systems

- Control and monitoring equipment

- Safety systems and certifications

Autoclaves work well for thick products and complex shapes requiring uniform curing.

Hot Air Ovens Hot air ovens provide precise temperature control for sensitive curing applications. Features include:

- Uniform temperature distribution

- Programmable temperature profiles

- Product handling systems

- Ventilation for volatile removal

- Energy efficiency features

Quality Control and Testing Equipment

Physical Property Testing Essential testing equipment includes:

- Tensile testing machines for strength measurements

- Hardness testers for durometer readings

- Compression set apparatus

- Tear resistance testers

- Abrasion testing equipment

Chemical Analysis Equipment Chemical testing capabilities include:

- Infrared spectroscopy for composition analysis

- Gas chromatography for volatile analysis

- Thermal analysis equipment

- Ash content determination

- Specific gravity measurement

Dimensional Inspection Tools Precision measurement requires:

- Coordinate measuring machines (CMM)

- Optical comparators

- Thickness gauges

- Surface finish analyzers

- Automated inspection systems

Starting a Rubber Product Manufacturing Unit

Starting a rubber product manufacturing unit requires systematic approach covering legal, technical, and operational aspects. Success depends on careful execution of each startup phase.

Proper startup planning ensures smooth operations while minimizing risks and delays. Consider all regulatory requirements and operational challenges before beginning production.

Legal and Regulatory Requirements

Business Registration and Licensing Register your manufacturing business according to local regulations. Required registrations typically include:

- Business entity formation (corporation, LLC, partnership)

- Manufacturing license applications

- Environmental permits and clearances

- Fire safety and building permits

- Tax registrations and accounts

Consult legal advisors familiar with manufacturing regulations in your jurisdiction.

Environmental Compliance Rubber processing generates emissions and waste requiring environmental permits. Key requirements include:

- Air emission permits for volatile compounds

- Water discharge permits for process water

- Waste management permits for solid waste

- Hazardous material storage permits

- Environmental impact assessments

Work with environmental consultants to ensure full compliance.

Safety and Health Regulations Manufacturing facilities must comply with occupational safety standards. Requirements include:

- Workplace safety assessments

- Employee health and safety training

- Safety equipment and procedures

- Emergency response planning

- Regular safety audits and inspections

Implement comprehensive safety programs from day one.

Facility Design and Layout

Production Flow Optimization Design facility layout to optimize material flow and minimize handling. Consider:

- Raw material receiving and storage areas

- Production equipment arrangement

- Work-in-process storage locations

- Finished goods storage and shipping

- Quality control and testing areas

Efficient layout reduces costs and improves productivity.

Utility Infrastructure Planning Ensure adequate utility capacity for equipment requirements:

- Electrical power with appropriate voltage and capacity

- Compressed air systems for pneumatic equipment

- Steam or hot water for heating applications

- Chilled water for cooling systems

- Waste treatment and disposal systems

Plan for future expansion when sizing utility systems.

Safety and Environmental Features Incorporate safety and environmental protection features:

- Ventilation systems for emission control

- Fire suppression and detection systems

- Emergency shower and eyewash stations

- Spill containment and cleanup equipment

- Noise control measures

Staffing and Training Programs

Key Personnel Recruitment Identify and recruit essential staff positions:

- Plant manager with rubber industry experience

- Production supervisors and operators

- Quality control technicians

- Maintenance technicians

- Safety coordinator

Start recruitment early as experienced personnel may be difficult to find.

Training Program Development Develop comprehensive training programs covering:

- Equipment operation procedures

- Safety protocols and emergency procedures

- Quality control methods and standards

- Maintenance procedures and schedules

- Continuous improvement techniques

Ongoing training ensures consistent performance and safety.

Performance Management Systems Establish systems for monitoring and improving performance:

- Production metrics and reporting

- Quality control tracking

- Safety performance indicators

- Employee development programs

- Incentive and recognition systems

Industrial Setup for Rubber Product Line

Creating an efficient industrial setup for rubber product lines requires careful planning of equipment integration, workflow optimization, and quality systems. The right setup maximizes productivity while ensuring consistent product quality.

Modern rubber product lines integrate multiple processing steps into coordinated systems. This integration reduces handling, minimizes contamination, and improves overall efficiency.

Production Line Configuration

Sequential Process Integration Design production lines with logical process flow:

- Raw material preparation and weighing

- Mixing and compounding operations

- Shaping and forming processes

- Curing and vulcanization stages

- Finishing and quality control

- Packaging and shipping preparation

Each stage should feed efficiently into the next without bottlenecks or delays.

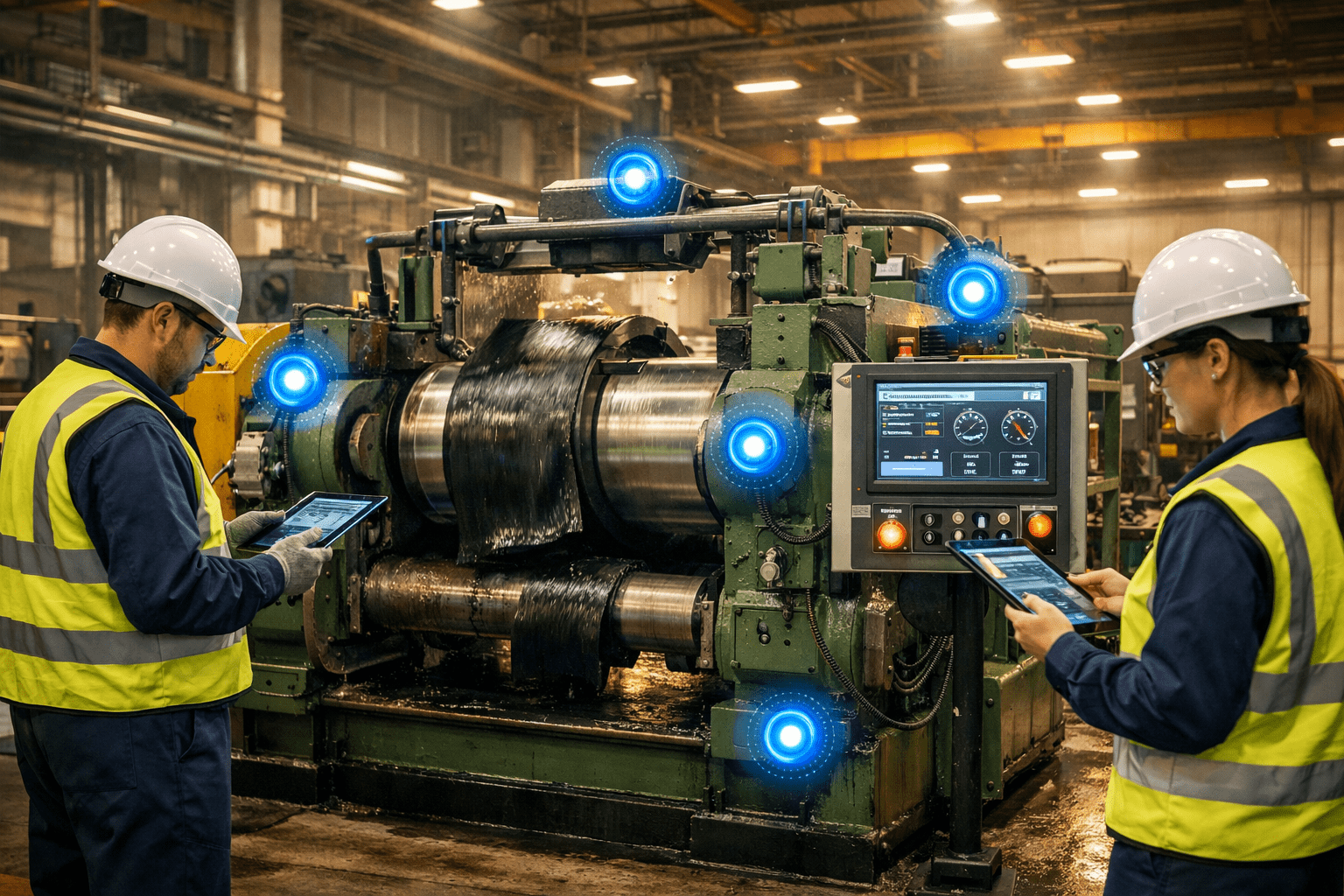

Automation and Control Integration Modern production lines incorporate automation for:

- Material handling between processes

- Process parameter monitoring and control

- Quality inspection and sorting

- Data collection and analysis

- Production scheduling and tracking

Automation reduces labor costs while improving consistency and quality.

Flexibility and Changeover Capabilities Design lines for multiple product capabilities:

- Quick mold changes for different products

- Recipe management systems for various compounds

- Adjustable processing parameters

- Modular equipment arrangements

- Standardized tooling and fixtures

Flexibility enables efficient production of diverse product ranges.

Quality Management Systems

Statistical Process Control (SPC) Implement SPC throughout production processes:

- Real-time monitoring of critical parameters

- Control charts for process stability

- Capability studies for process validation

- Corrective action protocols

- Continuous improvement programs

SPC prevents defects and ensures consistent quality.

ISO Certification Requirements Many customers require ISO 9001 certification. Implementation includes:

- Quality management system documentation

- Process control procedures

- Calibration and maintenance programs

- Training and competency requirements

- Internal audit systems

ISO certification demonstrates commitment to quality and opens new market opportunities.

Customer-Specific Requirements Different industries have specific quality requirements:

- Automotive: TS 16949 certification

- Medical: ISO 13485 compliance

- Food contact: FDA regulations

- Aerospace: AS9100 standards

- Military: MIL-SPEC requirements

Understand customer requirements early in the planning process.

Supply Chain and Logistics

Raw Material Management Establish reliable supply chains for critical materials:

- Multiple suppliers for key materials

- Long-term contracts for price stability

- Just-in-time delivery systems

- Quality agreements with suppliers

- Inventory management systems

Reliable material supply prevents production disruptions.

Distribution and Shipping Plan efficient distribution systems:

- Warehouse and storage facilities

- Shipping and logistics partnerships

- Order management systems

- Customer service capabilities

- Return and warranty handling

Efficient distribution enhances customer satisfaction and reduces costs.

Technology and Innovation Integration

Modern rubber processing plants benefit significantly from advanced technologies and innovative approaches. Technology integration improves efficiency, quality, and competitiveness in global markets.

Innovation drives continuous improvement in rubber processing operations. Staying current with technological advances ensures long-term success and market leadership.

Digital Manufacturing Technologies

Process Automation Systems Advanced automation systems coordinate all plant operations:

- Manufacturing Execution Systems (MES)

- Enterprise Resource Planning (ERP) integration

- Real-time production monitoring

- Automated quality control systems

- Predictive maintenance capabilities

Digital systems provide unprecedented visibility and control over operations.

Industry 4.0 Implementation Industry 4.0 technologies transform rubber manufacturing:

- Internet of Things (IoT) sensor networks

- Artificial intelligence for process optimization

- Machine learning for quality prediction

- Digital twin modeling

- Cloud-based data analytics

These technologies enable smart manufacturing capabilities.

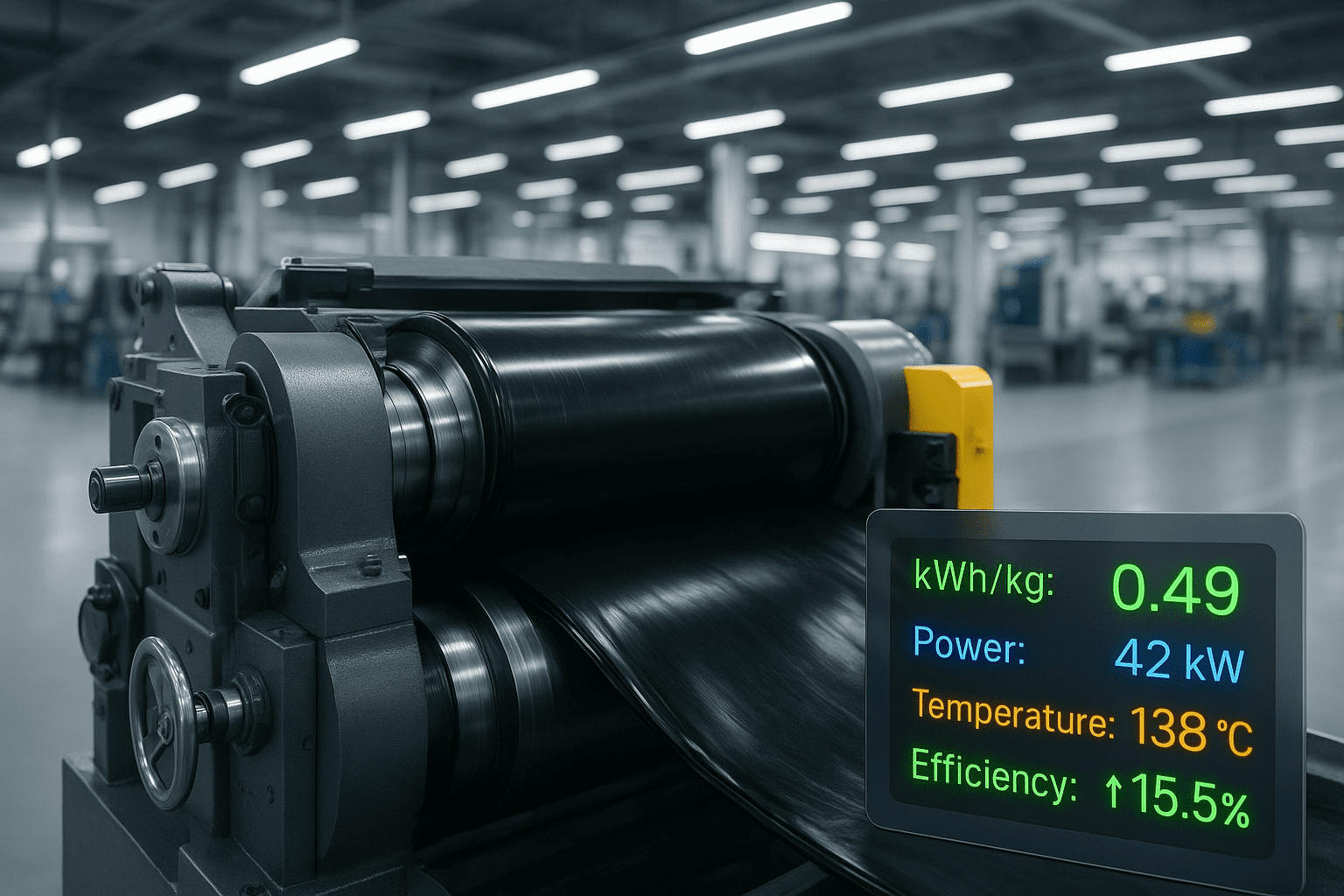

Data Analytics and Optimization Advanced analytics optimize plant performance:

- Production efficiency analysis

- Energy consumption optimization

- Quality trend analysis

- Maintenance cost reduction

- Customer demand forecasting

Data-driven decisions improve all aspects of operations.

Sustainability and Environmental Technology

Energy Efficiency Improvements Modern plants incorporate energy-saving technologies:

- Variable frequency drives for motor control

- Heat recovery systems

- High-efficiency lighting systems

- Power factor correction equipment

- Energy monitoring and management systems

Energy efficiency reduces costs and environmental impact.

Waste Reduction Technologies Advanced waste management systems include:

- Rubber recycling and reprocessing

- Solvent recovery systems

- Water treatment and reuse

- Waste heat utilization

- Packaging optimization

Waste reduction improves profitability and environmental performance.

Environmental Monitoring Systems Continuous monitoring ensures compliance:

- Air emission monitoring

- Water quality testing

- Noise level measurement

- Waste tracking systems

- Environmental reporting tools

Proactive monitoring prevents violations and demonstrates environmental responsibility.

Financial Planning and Investment Strategies

Successful rubber processing plant setup requires comprehensive financial planning and appropriate investment strategies. Proper financial management ensures adequate funding and sustainable profitability.

Financial planning must consider both initial investment requirements and long-term operational needs. Diverse funding sources and careful cash flow management support business growth and stability.

Funding Options and Sources

Traditional Bank Financing Commercial banks offer various financing options:

- Term loans for equipment purchases

- Lines of credit for working capital

- Equipment financing arrangements

- Real estate mortgages for facilities

- Letters of credit for international transactions

Banks require detailed business plans and financial projections for loan approval.

Government Incentives and Programs Many governments offer manufacturing incentives:

- Tax credits for new equipment purchases

- Grants for job creation

- Low-interest loans for small businesses

- Export development programs

- Research and development incentives

Research available programs in your jurisdiction for potential savings.

Private Investment and Partnerships Alternative funding sources include:

- Private equity investors

- Strategic partnerships with customers

- Joint ventures with technology providers

- Angel investors for startup funding

- Crowdfunding for consumer products

Each option involves different terms and control considerations.

Financial Management Best Practices

Cash Flow Management Maintain positive cash flow through:

- Accurate sales forecasting

- Efficient accounts receivable collection

- Strategic accounts payable timing

- Inventory optimization

- Seasonal planning

Strong cash flow management prevents financial crises and enables growth investments.

Cost Control Systems Implement comprehensive cost control:

- Standard costing systems

- Variance analysis procedures

- Budget monitoring and reporting

- Cost reduction programs

- Benchmarking against competitors

Effective cost control maintains profitability in competitive markets.

Performance Measurement Track key financial metrics:

- Gross profit margins by product

- Return on invested capital

- Inventory turnover rates

- Asset utilization ratios

- Customer profitability analysis

Regular performance measurement guides decision-making and identifies improvement opportunities.

Risk Management and Mitigation Strategies

Rubber processing operations face various risks requiring proactive management and mitigation strategies. Comprehensive risk management protects investments and ensures business continuity.

Effective risk management identifies potential threats early and implements appropriate preventive measures. This approach minimizes disruptions and protects long-term profitability.

Operational Risk Management

Equipment Failure Prevention Minimize equipment-related risks through:

- Comprehensive preventive maintenance programs

- Redundant equipment for critical processes

- Emergency repair procedures and spare parts inventory

- Equipment monitoring and predictive maintenance

- Regular safety inspections and updates

Equipment reliability ensures consistent production and customer satisfaction.

Supply Chain Risk Mitigation Protect against supply disruptions:

- Multiple suppliers for critical materials

- Strategic inventory management

- Alternative material qualifications

- Long-term supplier agreements

- Supply chain monitoring systems

Diversified supply chains prevent production interruptions.

Quality Risk Management Maintain consistent quality through:

- Robust quality control systems

- Statistical process control implementation

- Supplier quality agreements

- Customer complaint tracking

- Continuous improvement programs

Quality problems damage reputation and increase costs significantly.

Financial Risk Protection

Market Risk Management Protect against market volatility:

- Diversified customer base

- Multiple product lines

- Geographic market diversification

- Long-term customer contracts

- Market intelligence systems

Market diversification reduces dependence on single customers or markets.

Currency and Commodity Risk Manage price volatility through:

- Commodity hedging strategies

- Currency hedging for international sales

- Price adjustment clauses in contracts

- Strategic inventory management

- Supplier negotiation strategies

Financial hedging tools protect against unexpected cost increases.

Insurance Coverage Comprehensive insurance protection includes:

- Property insurance for facilities and equipment

- Business interruption coverage

- Product liability insurance

- Workers’ compensation coverage

- Cyber liability protection

Adequate insurance coverage protects against catastrophic losses.

Conclusion

Setting up a successful rubber processing plant requires careful planning, adequate investment, and systematic execution. This comprehensive guide provides the foundation for making informed decisions throughout the setup process.

Success depends on thorough market research, appropriate equipment selection, regulatory compliance, and effective financial management. Each element contributes to long-term profitability and market competitiveness.

The rubber industry offers significant opportunities for well-planned manufacturing operations. Growing demand across automotive, construction, and industrial markets creates favorable conditions for new entrants.

Remember that rubber processing plant setup is a complex undertaking requiring expertise in multiple areas. Consider consulting with industry experts, equipment suppliers, and professional advisors throughout the process.

With proper planning and execution, your rubber processing plant can achieve sustainable profitability while serving important industrial markets. Focus on quality, efficiency, and customer satisfaction to build a successful long-term business.

Start your planning today and take the first step toward establishing your rubber processing operation. The opportunities are significant for those who plan carefully and execute professionally.