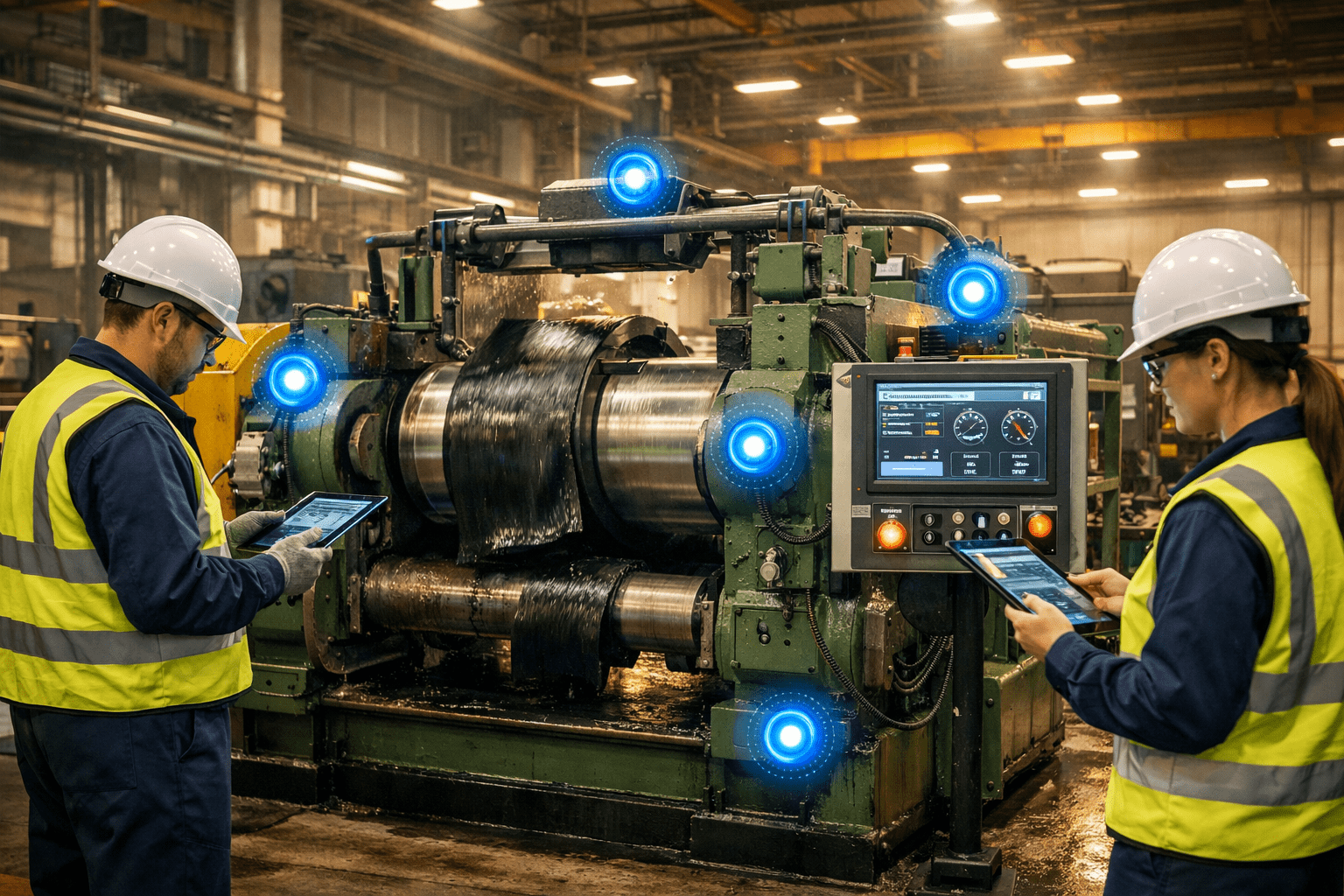

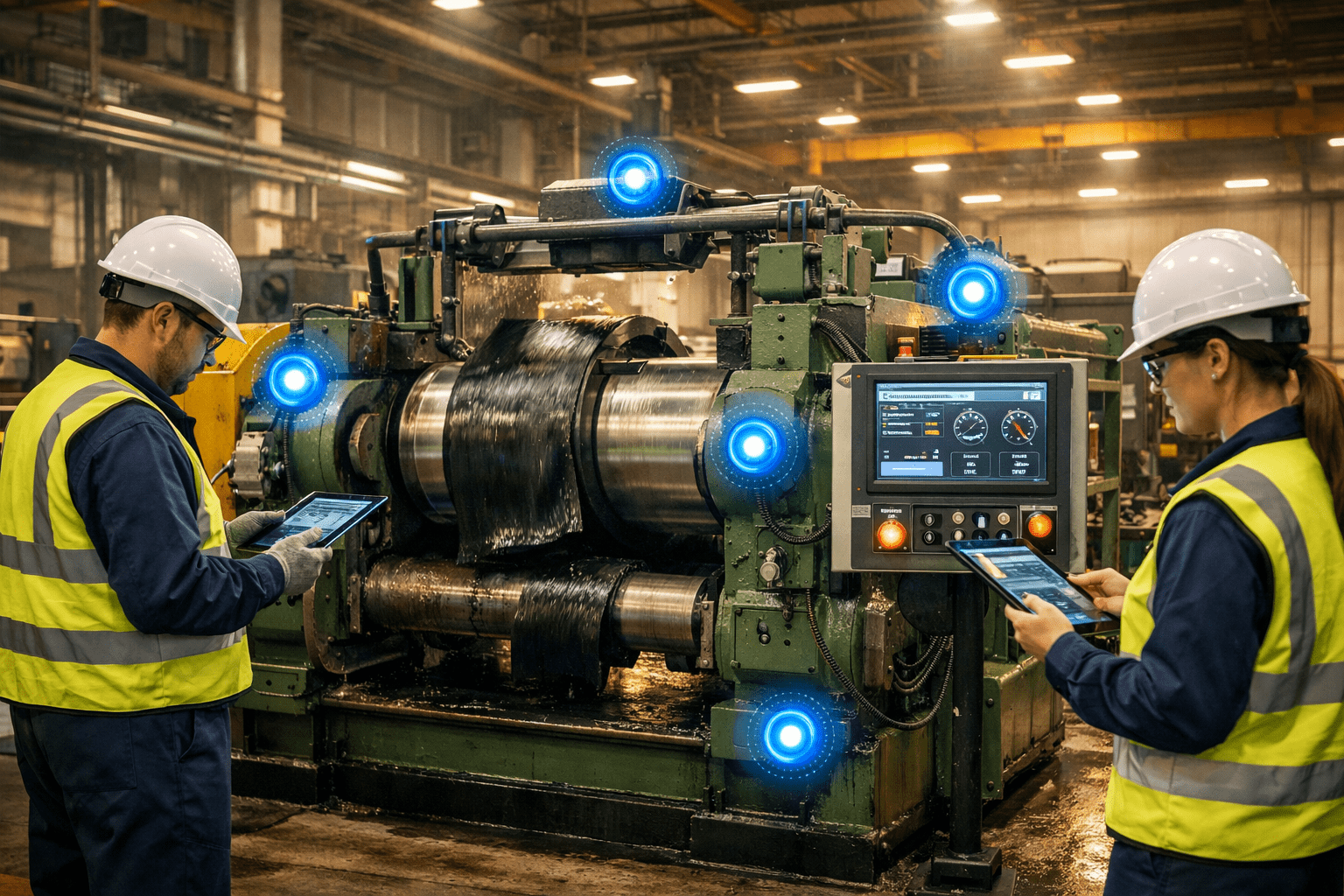

Retrofitting Old Rubber Machinery for Industry 4.0: Cost, Benefits & Quick Wins

When the production manager at a mid-sized rubber components plant in Gujarat walked into his facility one Monday morning, he faced a familiar problem: nearly

When the production manager at a mid-sized rubber components plant in Gujarat walked into his facility one Monday morning, he faced a familiar problem: nearly

When Mumbai-based rubber component manufacturer Precision Seals was struggling with mounting scrap rates that were eating into their profits, they knew something had to change.

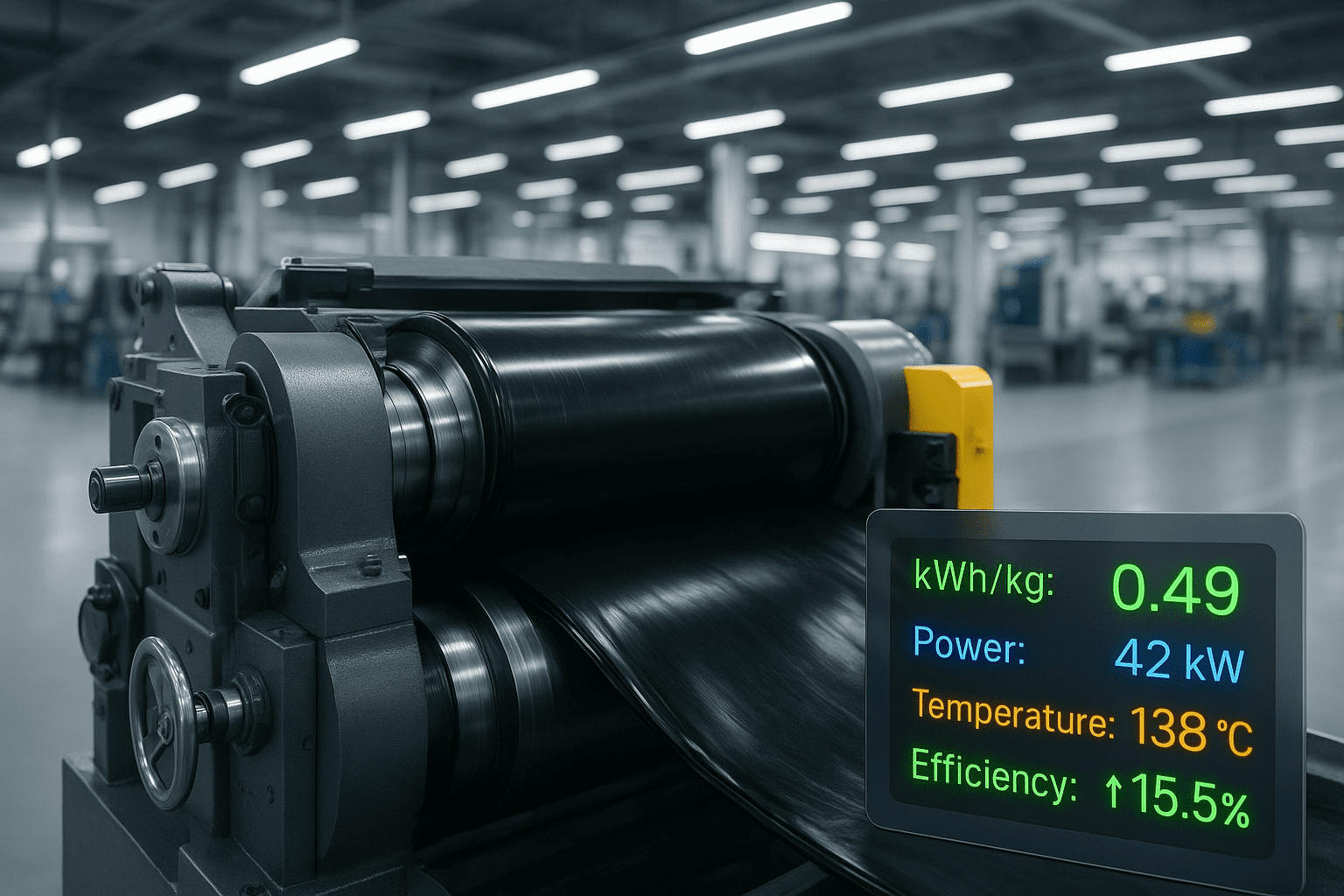

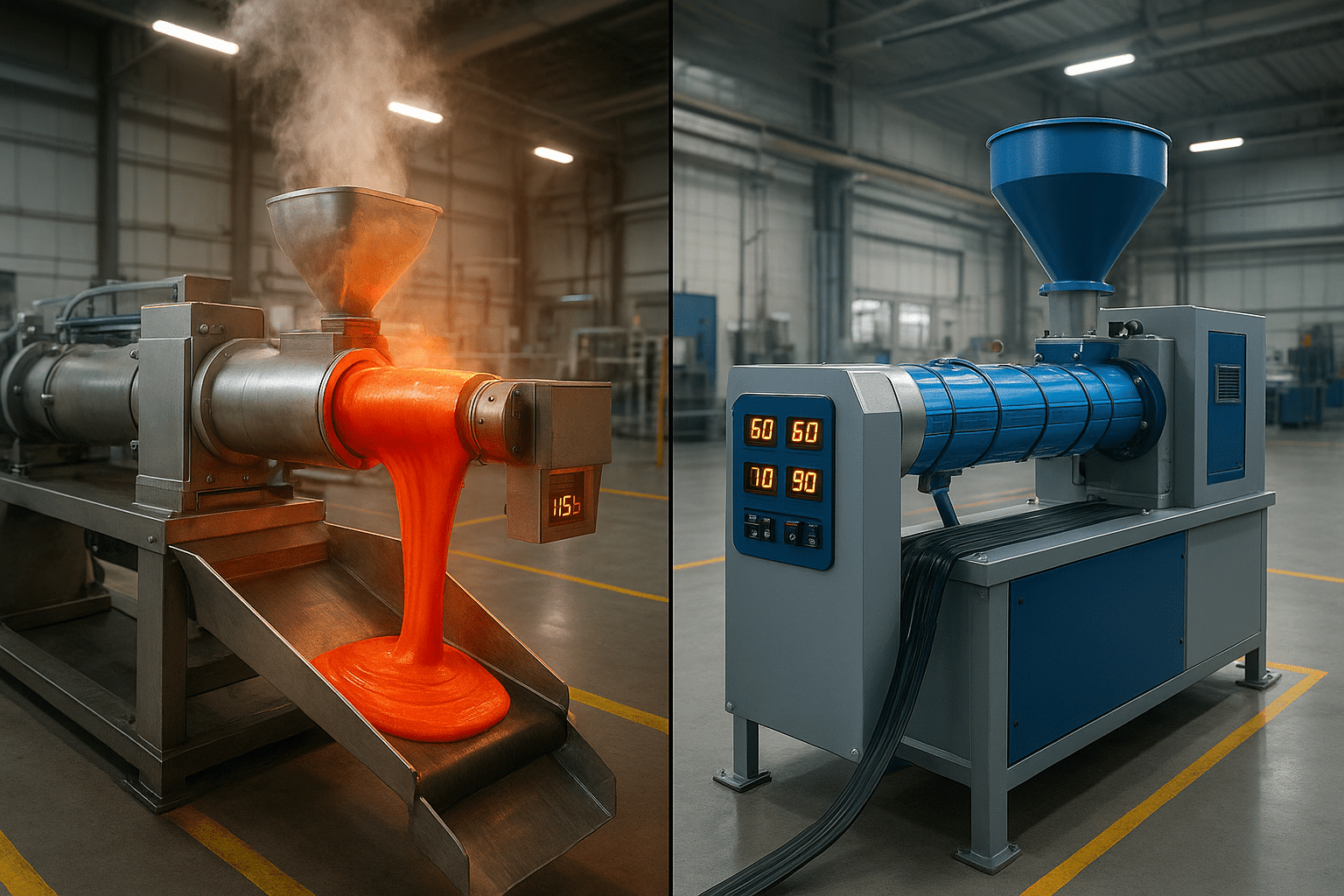

Rubber manufacturers face increasing pressure to trim operational costs without sacrificing product quality. Energy consumption stands out as one of the biggest expenses—especially in extrusion

Choosing the right extruder for your rubber processing line isn’t just about specs—it’s about matching the technology to your product requirements, production volume, and quality

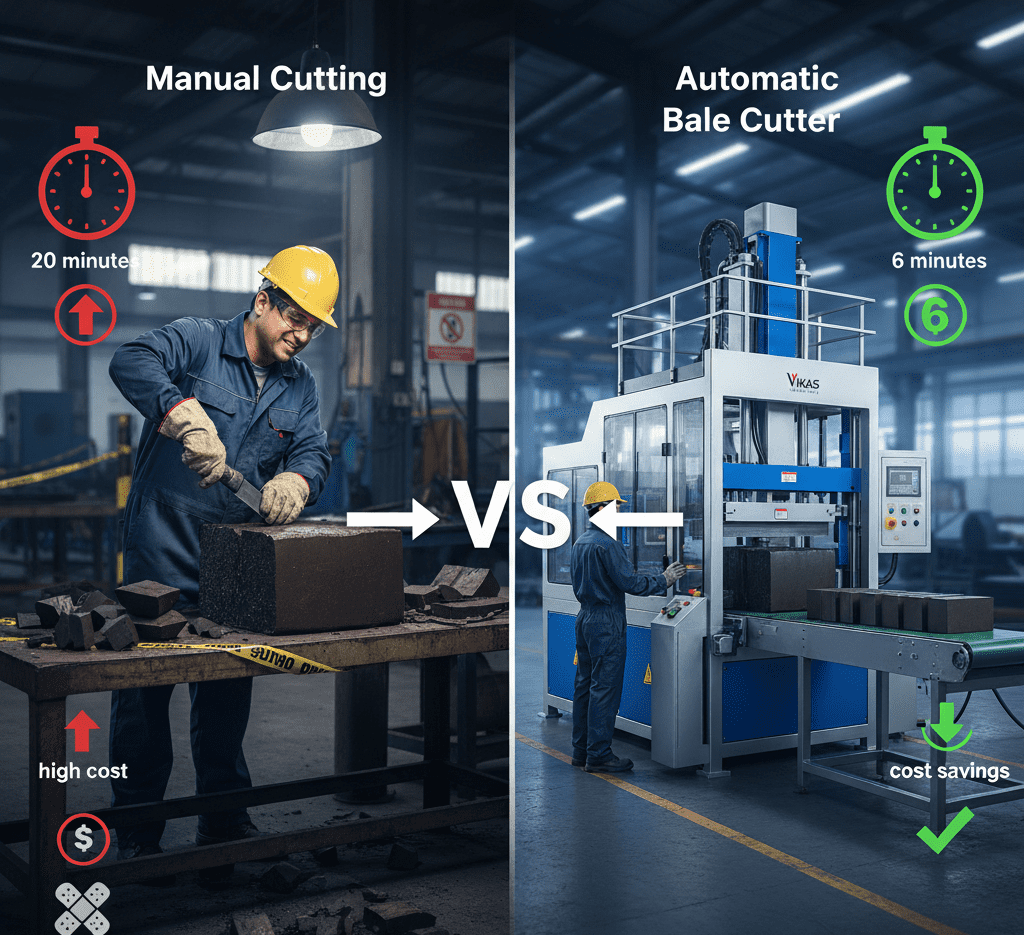

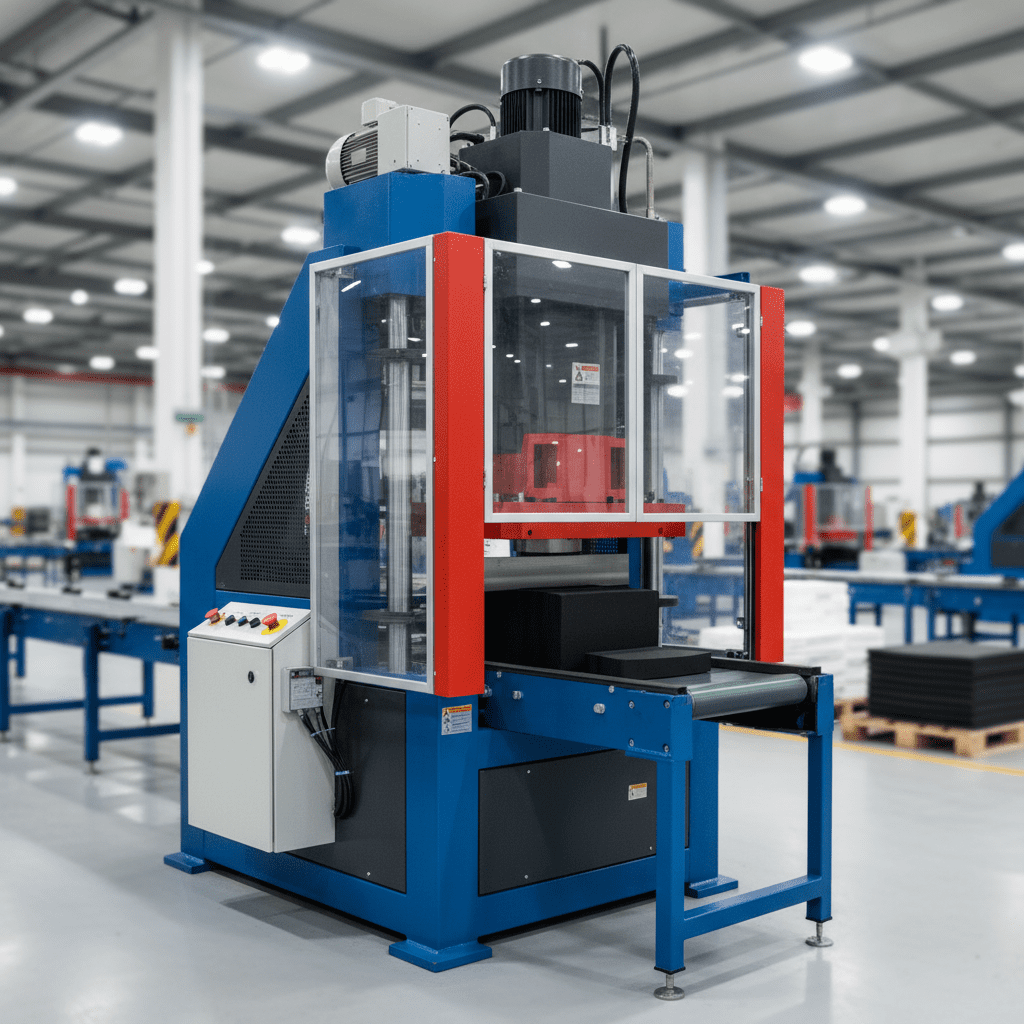

If you’re still manually cutting rubber bales in your processing facility, you’re likely bleeding money, time, and safety—without even realizing it. The debate between investing

In the rubber processing industry, efficiency and safety aren’t just buzzwords—they’re the foundation of profitable operations. One piece of equipment that dramatically impacts both metrics

Every morning at 6:45 AM, Rajesh Kumar walks into his rubber manufacturing plant in Pune. Before the production line starts humming, he’s already halfway through

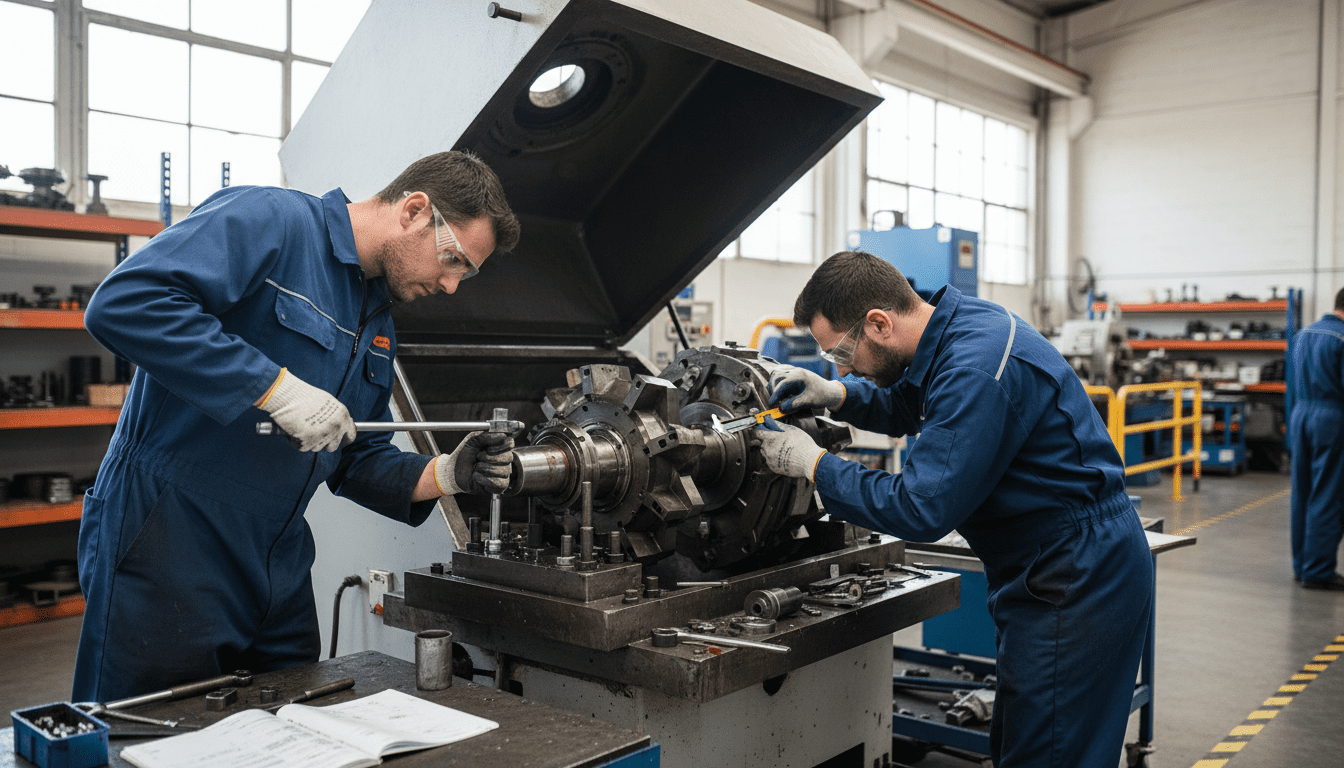

When your dispersion kneader stops working efficiently, every minute of downtime costs money. After manufacturing rubber processing machinery for years at Vikas Industries, we’ve seen—and

© 2024 Vikas Industries, All right reserved.

Vikas Industries

Hi There

Any Query Related to Machinery?

Start Chat

WhatsApp us