The rubber manufacturing industry is experiencing a technological revolution. Modern rubber mixing mills are leading this transformation with groundbreaking innovations that are changing how companies approach rubber compounding and processing.

Traditional mixing methods are being replaced by cutting-edge systems that offer better control, higher efficiency, and superior product quality. These advancements are helping manufacturers meet growing demands while reducing costs and environmental impact.

This guide explores the most significant innovations in rubber mixing mill technology. You’ll discover how automated systems, energy-efficient designs, and smart technology are reshaping the future of rubber processing.

Revolutionary Automated Rubber Mixing Technology

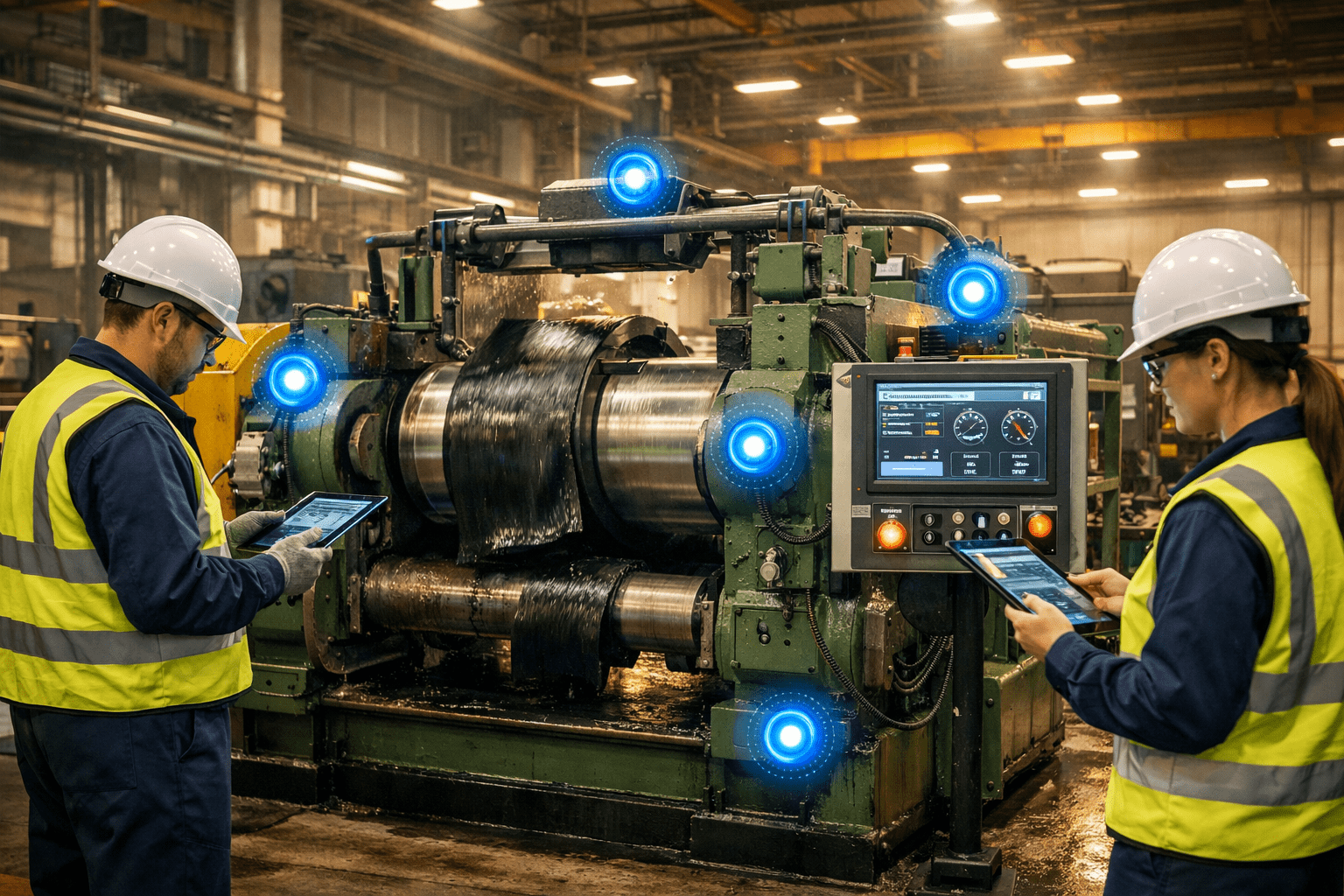

Automated rubber mixing technology is transforming how manufacturers approach rubber compounding. These systems eliminate human error while delivering consistent results across every production run.

Modern automation systems use precise sensors to monitor temperature, pressure, and mixing speed in real-time. This constant monitoring ensures optimal mixing conditions throughout the entire process.

Key benefits of automated mixing systems include:

- Reduced labor costs and human error

- Consistent product quality across all batches

- Faster production cycles and higher throughput

- Better safety for workers and equipment

- Precise control over mixing parameters

Advanced control systems can automatically adjust mixing parameters based on material properties and desired outcomes. This smart technology learns from previous batches to optimize future production runs.

Robotic process automation is also being integrated into mixing operations. These systems can handle material loading, unloading, and quality testing without human intervention.

The latest automated rubber mixing technology includes predictive maintenance features. These systems monitor equipment health and predict when maintenance is needed, preventing costly breakdowns.

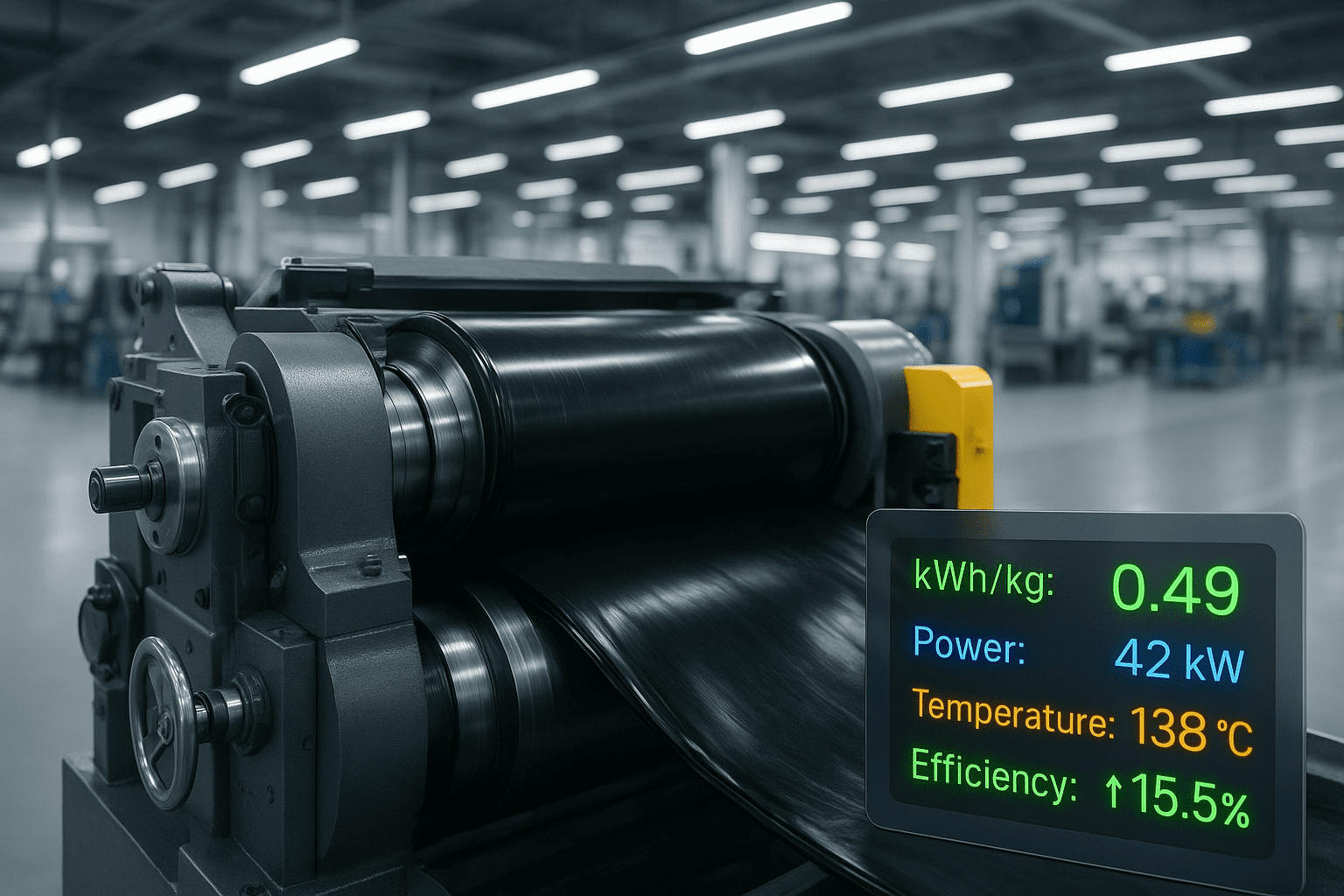

Energy-Efficient Mixing Mills: Reducing Costs and Environmental Impact

Energy-efficient mixing mills are addressing two critical industry challenges: rising energy costs and environmental sustainability. These innovative systems can reduce energy consumption by up to 40% compared to traditional mills.

Modern energy-efficient designs use advanced motor technology and optimized mechanical systems. Variable frequency drives allow motors to operate at optimal speeds, reducing unnecessary energy consumption.

Heat recovery systems capture and reuse thermal energy generated during mixing. This recovered energy can be used for preheating materials or other facility heating needs.

Improved insulation and thermal management systems minimize heat loss during operation. This reduces the energy needed to maintain optimal mixing temperatures.

Smart energy management features include:

- Real-time energy monitoring and reporting

- Automatic shutdown during idle periods

- Optimized mixing cycles to reduce processing time

- Power factor correction to improve electrical efficiency

- Integration with renewable energy sources

Energy-efficient mixing mills also feature lightweight components and precision engineering. These improvements reduce the power needed to operate mixing rotors and drive systems.

Advanced cooling systems use less energy while maintaining optimal operating temperatures. Some systems use air cooling instead of water cooling to eliminate pump energy consumption.

Smart Mixing Mill Systems: The Future of Rubber Processing

Smart mixing mill systems represent the next generation of rubber processing technology. These intelligent systems use artificial intelligence and machine learning to optimize every aspect of the mixing process.

Internet of Things (IoT) connectivity allows mills to communicate with other equipment and management systems. This connectivity enables real-time monitoring and control from anywhere in the facility or remotely.

Smart systems collect vast amounts of data during operation. This data is analyzed to identify patterns and optimize mixing parameters for different rubber compounds.

Key features of smart mixing mill systems include:

- Predictive analytics for quality control

- Remote monitoring and diagnostics

- Automatic recipe adjustment based on material properties

- Integration with enterprise resource planning systems

- Real-time production tracking and reporting

Machine learning algorithms continuously improve mixing processes by analyzing historical data. These systems can predict optimal mixing times, temperatures, and speeds for new compound formulations.

Smart mixing mills also feature advanced user interfaces with touchscreen controls and intuitive software. Operators can easily monitor multiple parameters and make adjustments without extensive training.

Digital twin technology creates virtual models of mixing operations. These models allow engineers to test new processes and optimize settings before implementing changes on actual equipment.

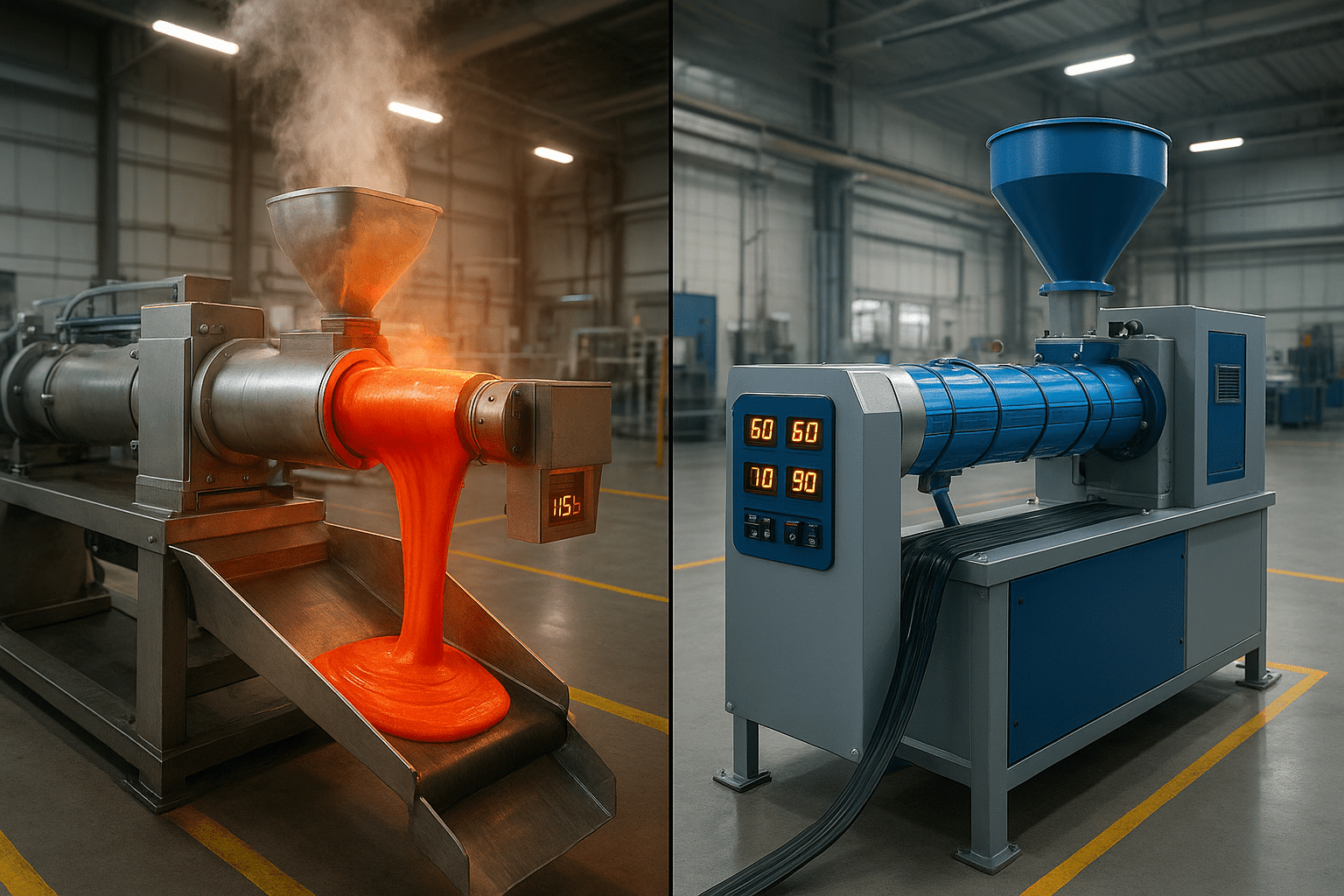

Advanced Materials and Design Innovations in Rubber Compounding

Innovations in rubber compounding are driving demand for more sophisticated mixing equipment. New rubber formulations require precise control and specialized mixing capabilities.

Advanced rotor designs improve mixing efficiency and reduce processing times. Specialized rotor geometries create optimal shear patterns for different types of rubber compounds.

Temperature control systems have become more precise and responsive. Some systems can maintain temperatures within 1°C of target settings throughout the mixing cycle.

Modern mixing chambers feature improved wear resistance and longer service life. Advanced coatings and materials reduce maintenance requirements and improve product quality.

Key design innovations include:

- Modular mixing chamber designs for easy maintenance

- Quick-change rotor systems for different compound types

- Advanced sealing systems to prevent contamination

- Improved discharge systems for faster batch cycles

- Specialized mixing elements for specific applications

New mixing chamber geometries optimize material flow and reduce mixing times. Some designs incorporate multiple mixing zones with different shear characteristics.

Advanced material handling systems automatically feed precise amounts of ingredients. These systems ensure consistent compound formulations and reduce waste.

Temperature profiling technology allows different zones of the mixing chamber to operate at different temperatures. This enables more precise control over compound development.

Digital Integration and Industry 4.0 Applications

Digital integration is transforming rubber mixing operations through Industry 4.0 technologies. These systems connect mixing mills with broader manufacturing networks for improved efficiency and control.

Cloud-based monitoring systems allow manufacturers to track multiple mills across different locations. This connectivity enables centralized control and standardized processes.

Digital integration features include:

- Real-time production dashboards

- Automated quality control systems

- Predictive maintenance scheduling

- Supply chain integration

- Remote technical support capabilities

Artificial intelligence systems analyze production data to identify optimization opportunities. These systems can recommend process improvements and predict potential quality issues.

Digital twin technology creates virtual replicas of mixing operations. Engineers can use these models to test new processes and optimize equipment settings without disrupting production.

Blockchain technology is being explored for tracking rubber compound formulations and ensuring quality traceability. This technology could revolutionize quality control and compliance reporting.

Advanced analytics platforms process data from multiple sources to provide comprehensive insights. These platforms can identify correlations between mixing parameters and final product properties.

Quality Control and Monitoring Innovations

Quality control innovations are ensuring consistent product quality while reducing testing time and costs. Modern systems can detect quality issues in real-time during the mixing process.

In-line testing systems analyze rubber compounds as they’re being mixed. These systems can detect deviations from specifications immediately, allowing for real-time corrections.

Advanced sensor technology monitors critical parameters throughout the mixing process:

- Viscosity measurements during mixing

- Temperature profiling across the mixing chamber

- Pressure monitoring for consistent processing

- Chemical composition analysis

- Physical property testing

Spectroscopic analysis systems can identify compound composition without removing samples. This non-destructive testing speeds up quality control while maintaining accuracy.

Statistical process control software tracks quality trends over time. This software can predict when processes are drifting out of specification before quality issues occur.

Automated sampling systems ensure representative samples are collected for testing. These systems eliminate human error in sample collection and preparation.

Machine vision systems inspect mixed compounds for visual defects and consistency. These systems can detect color variations, contamination, and mixing uniformity issues.

Safety and Environmental Advances

Safety innovations are protecting workers while reducing environmental impact. Modern mixing mills incorporate multiple safety systems and environmental protection features.

Advanced safety features include:

- Emergency stop systems with redundant controls

- Protective barriers with safety interlocks

- Automated material handling to reduce worker exposure

- Improved ventilation systems for dust and fume control

- Fire suppression systems designed for mixing operations

Environmental protection systems minimize emissions and waste. Closed-loop systems capture and recycle process materials to reduce waste generation.

Dust collection systems prevent rubber particles from entering the workplace environment. These systems protect worker health while maintaining clean production areas.

Water treatment systems process cooling water and cleaning solutions before discharge. This reduces environmental impact and may allow water reuse.

Noise reduction technologies make mixing operations quieter and more comfortable for workers. Sound dampening materials and vibration isolation systems reduce noise transmission.

Energy recovery systems capture waste heat for reuse in other processes. This reduces overall facility energy consumption and environmental impact.

Future Trends and Emerging Technologies

Emerging technologies promise even greater innovations in rubber mixing mill design and operation. These developments will further improve efficiency, quality, and sustainability.

Quantum computing may revolutionize compound formulation by rapidly analyzing complex molecular interactions. This technology could dramatically reduce development time for new rubber compounds.

Future trend predictions include:

- Fully autonomous mixing operations

- Nanotechnology applications in mixing processes

- Biotechnology integration for sustainable rubber production

- Advanced materials for longer equipment life

- Hydrogen fuel cell power systems for mobile mills

Augmented reality systems will assist operators with maintenance and troubleshooting. These systems can overlay digital information on physical equipment to guide repairs and adjustments.

3D printing technology may enable on-demand production of mixing mill components. This could reduce spare parts inventory and enable rapid customization of equipment.

Advanced artificial intelligence will enable mills to automatically develop new compound formulations. These systems could optimize recipes for specific performance requirements without human intervention.

Sustainable manufacturing practices will drive innovations in recyclable equipment design and bio-based rubber processing. These developments will support circular economy principles in rubber manufacturing.

Conclusion

Modern rubber mixing mills are revolutionizing the industry through innovative technology and design improvements. Automated rubber mixing technology is delivering unprecedented control and consistency, while energy-efficient mixing mills are reducing operational costs and environmental impact.

Smart mixing mill systems are ushering in a new era of intelligent processing that optimizes every aspect of rubber compounding. These innovations in rubber compounding technology are enabling manufacturers to produce higher quality products while improving efficiency and reducing costs.

The future of rubber mixing mills lies in continued integration of digital technologies, artificial intelligence, and sustainable design principles. Manufacturers who embrace these innovations will gain significant competitive advantages in the evolving rubber industry.

As technology continues advancing, we can expect even more revolutionary developments in mixing mill design and operation. The combination of automation, intelligence, and sustainability will define the next generation of rubber processing equipment.

Companies investing in modern rubber mixing mills today are positioning themselves for long-term success in an increasingly competitive and environmentally conscious marketplace. These technological innovations represent the foundation for the future of rubber manufacturing.