A dispersion kneader machine for rubber is essential equipment in the rubber processing industry. These powerful machines mix, knead, and disperse rubber compounds with precision and efficiency that traditional mixing methods cannot match.

Whether you’re manufacturing tires, seals, gaskets, or other rubber products, understanding dispersion kneader machines is crucial for your operation’s success. This comprehensive guide covers everything you need to know about these vital mixing systems.

What is a Dispersion Kneader Machine for Rubber?

A dispersion kneader machine for rubber is specialized mixing equipment designed to process rubber compounds through intensive mechanical action. These machines combine shearing, folding, and compressive forces to achieve uniform distribution of ingredients throughout the rubber matrix.

The kneader machine uses two counter-rotating rotors with specially designed blades. These rotors work inside a closed mixing chamber to create the intense mixing action needed for rubber compound development.

Key components include: • Mixing chamber with removable rotors • Hydraulic ram for material loading and discharge • Temperature control systems • Variable speed drives • Safety interlocks and monitoring systems

The dispersion process breaks down rubber bales and distributes fillers, oils, and other additives evenly. This creates homogeneous rubber compounds ready for further processing or molding.

Advantages of Dispersion Kneader Technology

The advantages of dispersion kneader systems make them indispensable in modern rubber manufacturing. These benefits directly impact product quality, production efficiency, and operational costs.

Superior Mixing Quality

Dispersion kneaders deliver exceptional mixing consistency compared to open mill mixing. The enclosed chamber design creates intense shear forces that break down ingredient agglomerates effectively.

The controlled mixing environment ensures: • Complete filler dispersion throughout the rubber matrix • Consistent batch-to-batch quality • Reduced variation in compound properties • Better carbon black and silica distribution

Enhanced Production Efficiency

These machines significantly reduce mixing times compared to traditional methods. A typical batch cycle ranges from 3-8 minutes, depending on the compound formulation.

Efficiency benefits include: • Faster batch cycles increase throughput • Automated operation reduces labor requirements • Consistent mixing eliminates rework batches • Integrated weighing systems improve accuracy

Improved Safety and Environmental Control

Enclosed mixing chambers contain dust and fumes that would otherwise escape during open mill processing. This creates a cleaner, safer working environment.

Safety advantages include: • Reduced operator exposure to chemicals • Better dust containment systems • Lower noise levels during operation • Automated material handling reduces injury risk

Cost-Effective Operation

While initial investment is higher than open mills, dispersion kneaders offer lower total cost of ownership through reduced labor, improved yield, and energy efficiency.

Economic benefits include: • Lower energy consumption per unit of mixed compound • Reduced material waste from consistent mixing • Higher productivity per operator • Lower maintenance costs with proper operation

Rubber Compound Dispersion Mixer Applications

Rubber compound dispersion mixer systems serve diverse applications across multiple industries. Understanding these applications helps determine the right equipment specifications for your needs.

Tire Manufacturing

The tire industry represents the largest application for rubber compound mixing equipment. Modern tire production requires precise compound development for different tire components.

Tire applications include: • Tread compounds with specific wear characteristics • Sidewall compounds for flex resistance • Bead compounds for high-strength requirements • Inner liner compounds for air retention

Each application demands different mixing parameters and compound properties. Dispersion kneaders provide the flexibility to handle these varied requirements efficiently.

Industrial Rubber Products

Manufacturing industrial rubber products requires compounds with specialized properties for demanding applications.

Industrial applications include: • Conveyor belt compounds for mining operations • Hydraulic seal compounds for extreme pressures • Vibration dampening compounds for machinery • Chemical-resistant compounds for processing equipment

Automotive Components

Beyond tires, automotive applications require numerous rubber components with specific performance characteristics.

Automotive applications include: • Engine mounts and bushings • Weather stripping and seals • Hoses and gaskets • Shock absorber components

Consumer Products

Consumer rubber products demand consistent quality and appearance that only precise mixing can deliver.

Consumer applications include: • Footwear soles and components • Sports equipment and recreational products • Household rubber goods • Medical and healthcare products

Kneader Machine for Rubber Industry Specifications

When selecting a kneader machine for rubber industry applications, understanding key specifications ensures optimal performance for your specific requirements.

Chamber Volume and Capacity

Chamber volume determines batch size and production capacity. Common sizes range from 1.5L laboratory units to 500L+ production machines.

Capacity considerations include: • Daily production requirements • Batch size optimization for efficiency • Material handling capabilities • Floor space limitations

Rotor Design and Configuration

Rotor design significantly impacts mixing effectiveness and compound quality. Different rotor profiles suit different applications.

Rotor types include: • Tangential rotors for general-purpose mixing • Intermeshing rotors for intensive dispersion • Non-intermeshing rotors for heat-sensitive compounds • Specialized profiles for specific applications

Drive System Specifications

The drive system provides the power needed for intensive mixing operations. Motor power typically ranges from 5HP for small units to 1000HP+ for large production machines.

Drive specifications include: • Motor power and torque characteristics • Variable speed control ranges • Overload protection systems • Energy efficiency ratings

Temperature Control Systems

Precise temperature control is critical for rubber compound development. Most systems include both heating and cooling capabilities.

Temperature control features include: • Jacket heating/cooling systems • Rotor temperature control • Automatic temperature regulation • Data logging and monitoring

Material Handling Systems

Efficient material handling improves productivity and reduces operator fatigue.

Handling systems include: • Hydraulic ram systems for discharge • Automatic weighing and feeding • Dust collection systems • Batch tracking capabilities

75L Rubber Dispersion Kneader Specifications

The 75L rubber dispersion kneader represents a popular mid-size option for many rubber processing operations. This capacity provides excellent balance between production capability and operational flexibility.

Physical Dimensions and Installation

A typical 75L dispersion kneader has specific space and utility requirements for proper installation and operation.

Physical specifications include: • Overall dimensions: approximately 3.5m x 2.0m x 2.5m • Operating weight: 8,000-12,000 kg depending on configuration • Foundation requirements for vibration isolation • Utility connections for power, water, and compressed air

Performance Capabilities

The 75L chamber volume provides sufficient capacity for medium-scale production while maintaining mixing quality.

Performance specifications include: • Batch weight capacity: 40-60 kg depending on compound density • Mixing cycle time: 3-8 minutes typical • Production capacity: 300-800 kg/hour depending on compound • Fill factor: 65-75% for optimal mixing

Power and Drive Requirements

Motor specifications for 75L kneaders typically range from 75-150 HP depending on application requirements.

Power specifications include: • Main drive motor: 110-150 HP typical • Rotor speed range: 20-40 RPM variable • Hydraulic system: 15-25 HP motor • Total connected load: 150-200 HP

Control and Automation Features

Modern 75L kneaders include sophisticated control systems for consistent operation and quality control.

Control features include: • PLC-based control systems • Recipe storage and recall • Temperature and time monitoring • Production data logging • Remote monitoring capabilities

Safety and Environmental Systems

Comprehensive safety systems protect operators and equipment during intensive mixing operations.

Safety features include: • Emergency stop systems • Safety interlocks on all access points • Dust collection and containment • Noise reduction enclosures • Operator training and safety protocols

Selecting the Right Dispersion Kneader Machine

Choosing the appropriate dispersion kneader requires careful analysis of your specific application requirements and production goals.

Production Requirements Analysis

Start by analyzing your current and projected production needs to determine the optimal machine size and configuration.

Consider these factors: • Daily production volume requirements • Batch size preferences for quality control • Number of different compounds processed • Shift patterns and operating schedules

Compound Characteristics

Different rubber compounds have varying mixing requirements that influence equipment selection.

Compound factors include: • Viscosity and hardness levels • Filler loading percentages • Temperature sensitivity • Chemical compatibility requirements

Quality and Consistency Requirements

Determine the level of mixing quality and batch-to-batch consistency needed for your applications.

Quality considerations include: • Dispersion quality requirements • Property variation tolerances • Testing and quality control procedures • Customer specification requirements

Budget and Return on Investment

Evaluate total cost of ownership including initial purchase price, installation costs, operating expenses, and expected return on investment.

Financial considerations include: • Capital equipment budget • Installation and startup costs • Operating cost projections • Payback period calculations • Financing options available

Installation and Setup Considerations

Proper installation is crucial for optimal performance and long-term reliability of dispersion kneader systems.

Site Preparation Requirements

Adequate site preparation ensures trouble-free installation and operation.

Site requirements include: • Reinforced concrete foundation design • Utility rough-in for power and water • Ventilation system planning • Material handling equipment access • Safety system integration

Utility Requirements

Dispersion kneaders require various utilities for proper operation.

Utility needs include: • Electrical power with proper voltage and phase • Process water for cooling systems • Compressed air for pneumatic controls • Waste heat recovery opportunities • Emergency power backup considerations

Training and Support

Comprehensive training ensures safe and efficient operation from startup.

Training components include: • Operator training programs • Maintenance procedures and schedules • Safety protocols and emergency procedures • Troubleshooting and diagnostic techniques • Ongoing technical support availability

Maintenance and Operational Best Practices

Proper maintenance and operation maximize equipment life and ensure consistent performance.

Preventive Maintenance Programs

Regular maintenance prevents unexpected downtime and extends equipment life.

Maintenance activities include: • Daily operational checks and inspections • Weekly lubrication and adjustment procedures • Monthly wear part inspections • Annual major component overhauls • Spare parts inventory management

Operational Optimization

Following best practices optimizes mixing quality and equipment performance.

Optimization techniques include: • Proper material sequencing and feeding • Temperature profile optimization • Mixing time and speed adjustments • Regular cleaning and sanitation procedures • Process monitoring and data analysis

Troubleshooting Common Issues

Understanding common problems and solutions minimizes production disruptions.

Common issues include: • Uneven mixing or poor dispersion quality • Excessive mixing times or energy consumption • Temperature control problems • Mechanical wear or component failures • Safety system malfunctions

Future Trends in Dispersion Kneader Technology

The rubber processing industry continues evolving with new technologies and changing market demands.

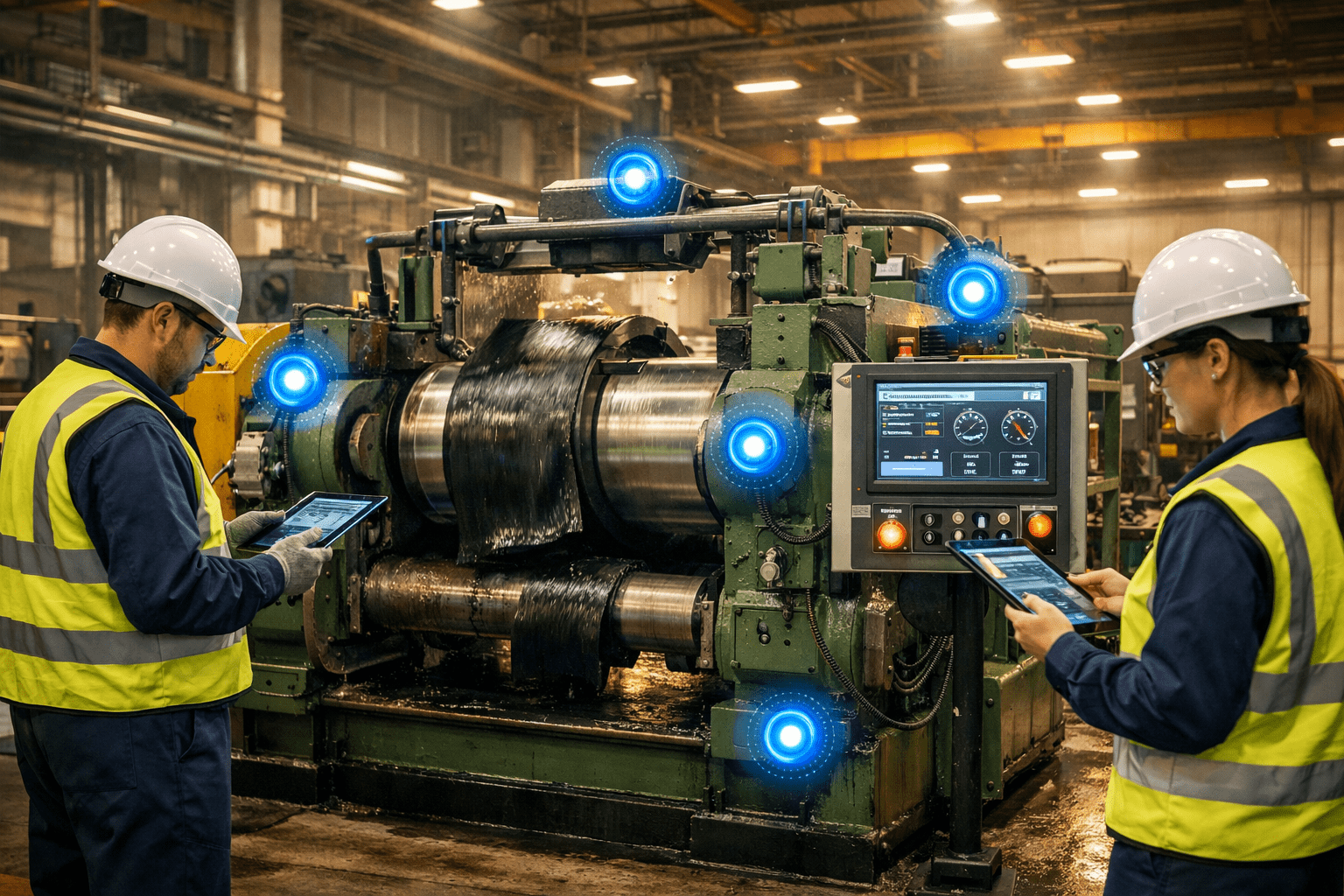

Automation and Industry 4.0

Advanced automation and connectivity improve efficiency and quality control.

Technology trends include: • Advanced process control systems • Predictive maintenance capabilities • Real-time quality monitoring • Integration with ERP systems • Remote monitoring and diagnostics

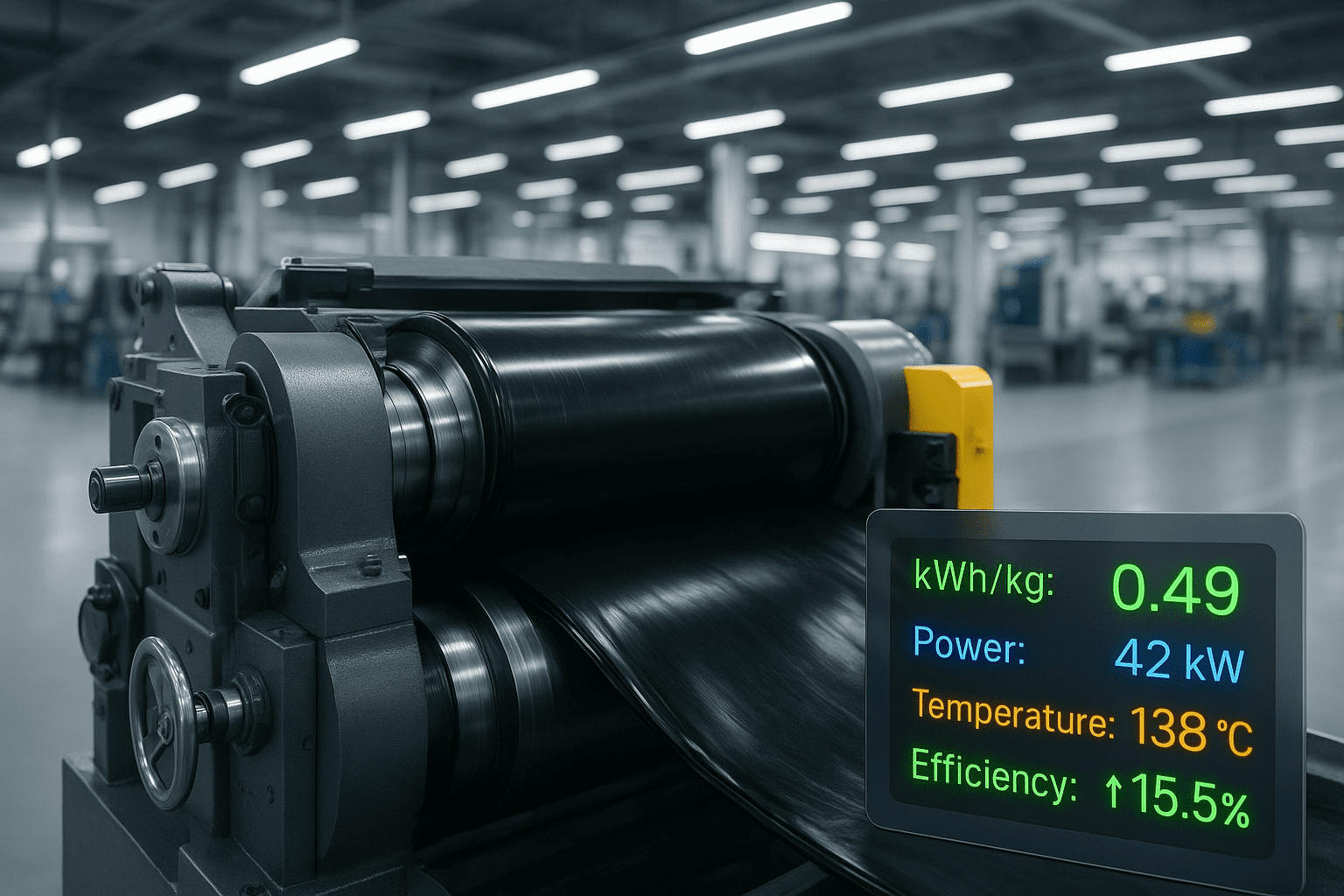

Energy Efficiency Improvements

Growing focus on sustainability drives energy efficiency innovations.

Efficiency improvements include: • Variable frequency drives for energy savings • Heat recovery systems • Improved insulation and thermal design • Energy monitoring and optimization • Renewable energy integration

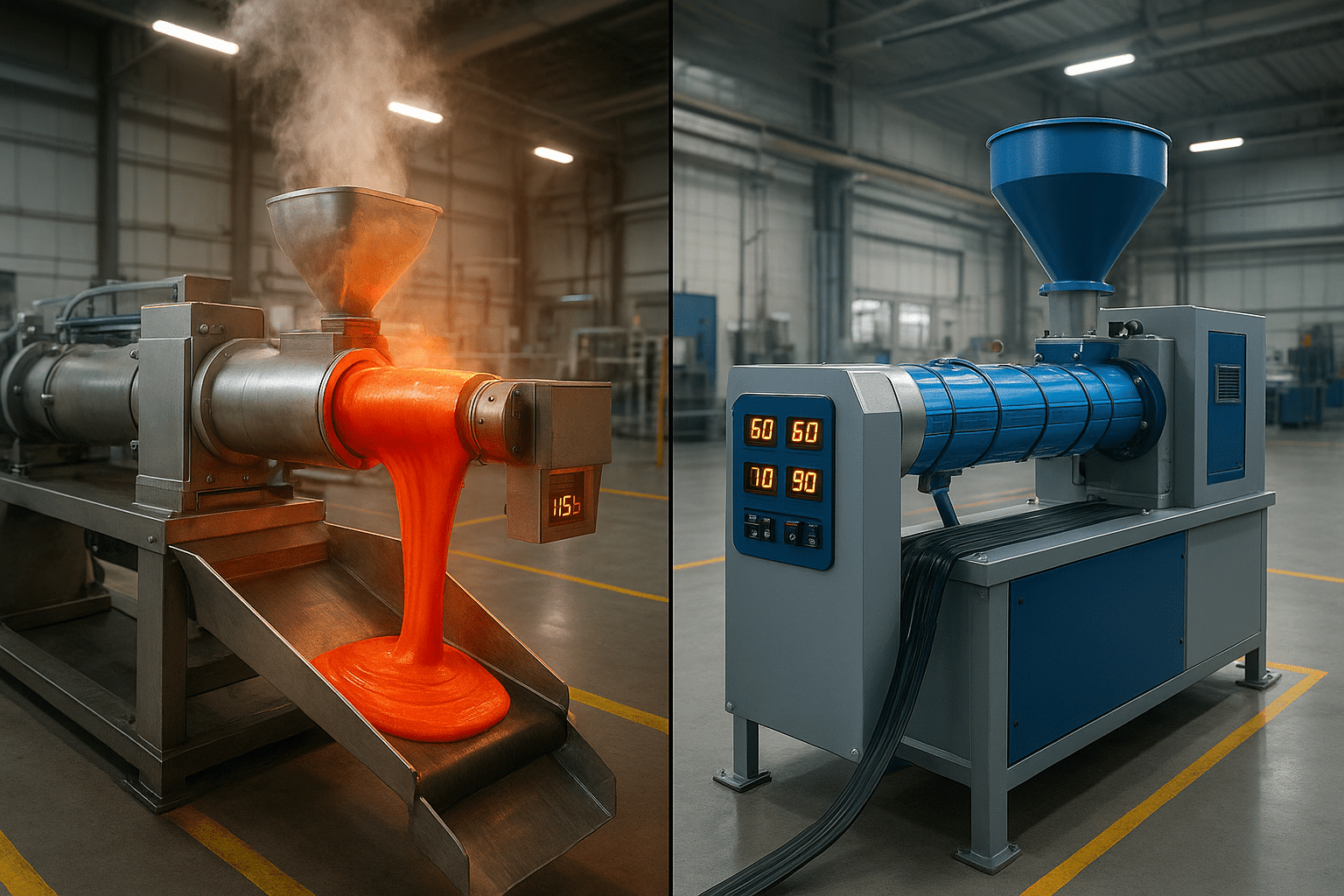

Advanced Materials Processing

New rubber compounds and additives require enhanced processing capabilities.

Processing advances include: • Specialized mixing profiles for new materials • Improved temperature control systems • Enhanced dispersion capabilities • Contamination prevention systems • Quality assurance integration

Conclusion

Dispersion kneader machines for rubber represent essential technology for modern rubber processing operations. Understanding their capabilities, specifications, and applications enables informed equipment selection decisions.

The advantages of dispersion kneader technology – including superior mixing quality, enhanced efficiency, improved safety, and cost-effective operation – make them indispensable for competitive rubber manufacturing.

When selecting equipment, consider your specific production requirements, compound characteristics, quality standards, and budget constraints. Proper installation, training, and maintenance ensure optimal performance and return on investment.

As the rubber industry continues evolving, dispersion kneader technology will adapt to meet new challenges and opportunities. Investing in quality equipment and proper operation practices positions your operation for long-term success in the competitive rubber market.

For more information about rubber processing equipment and techniques, visit the Rubber & Plastics News industry resources and the International Institute of Synthetic Rubber Producers technical library for the latest developments in rubber technology.