The rubber manufacturing industry is experiencing a technological revolution. Advanced rubber extrusion techniques are transforming how manufacturers produce high-quality rubber products with unprecedented precision and efficiency.

Modern extrusion methods combine cutting-edge technology with proven manufacturing principles. These innovations deliver superior product quality while reducing production costs and environmental impact.

Understanding Advanced Rubber Extrusion Technology

Advanced rubber extrusion represents the next generation of rubber processing technology. Unlike traditional methods, these techniques incorporate sophisticated control systems and precision engineering.

The core difference lies in the level of automation and control. Traditional extrusion relies heavily on operator experience and manual adjustments. Advanced systems use real-time monitoring and automated feedback loops.

Key Components of Modern Extrusion Systems

Modern extrusion lines feature several critical components:

- Precision feeding systems that ensure consistent material flow

- Advanced temperature control throughout the entire process

- Real-time monitoring sensors for quality assurance

- Automated cutting and handling equipment

- Data collection systems for process optimization

These components work together to create a seamless production environment. The integration of these systems results in higher quality products and reduced waste.

Learn more about rubber extrusion equipment and suppliers: https://extrudedrubber.net/

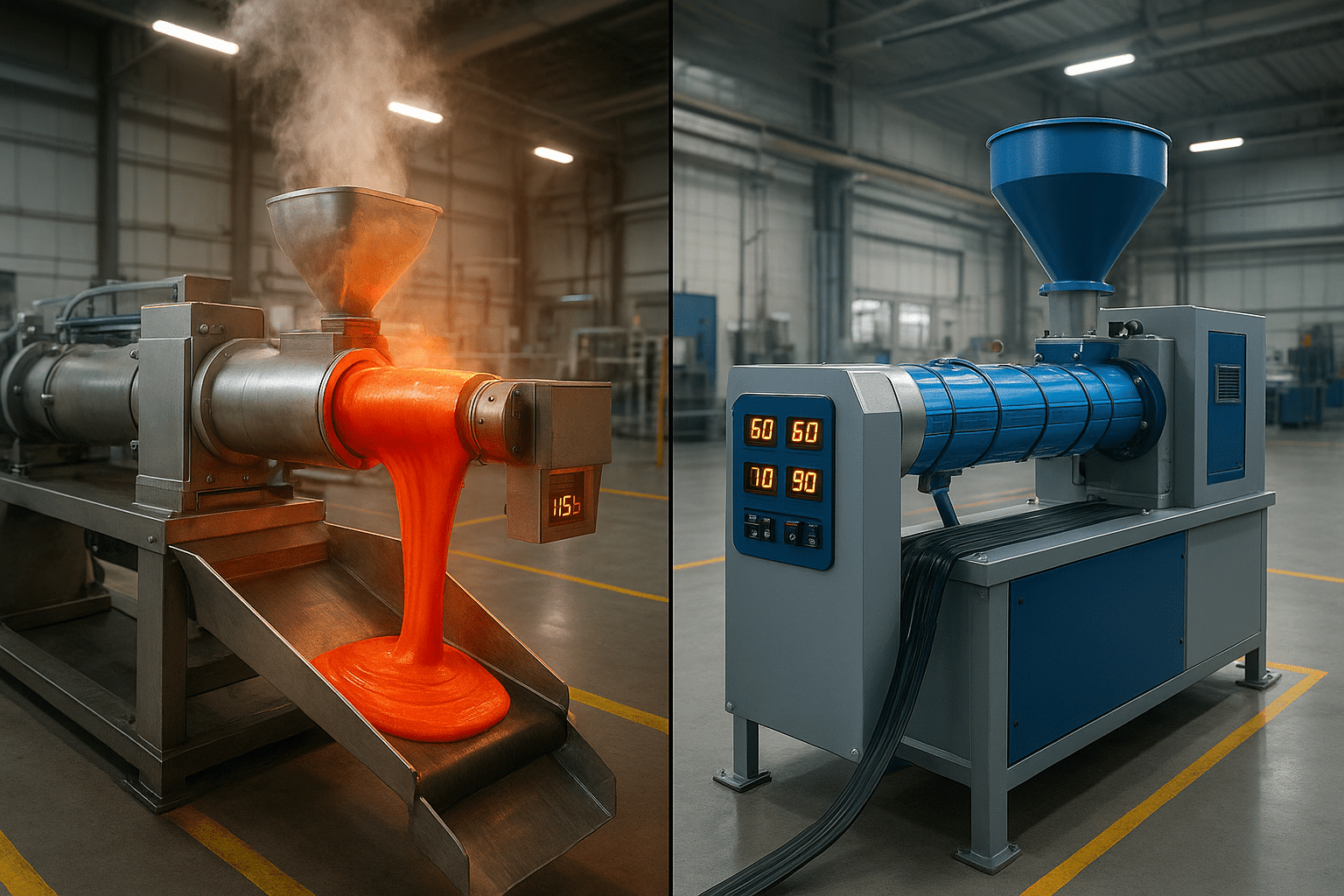

Evolution from Traditional Methods

Traditional rubber extrusion relied on mechanical systems with limited precision. Operators made adjustments based on visual inspection and manual measurements.

Advanced techniques use computer-controlled systems that make micro-adjustments automatically. This level of precision was impossible with older technology.

The transition to advanced methods typically involves upgrading existing equipment or investing in completely new production lines. Many manufacturers choose a phased approach to minimize disruption.

High-Precision Rubber Extruders: The Heart of Modern Production

High-precision rubber extruders are the cornerstone of advanced manufacturing operations. These machines deliver consistent results with minimal variation between products.

Precision extruders use sophisticated screw designs and barrel configurations. The geometry of these components directly impacts product quality and consistency.

Screw Design Innovations

Modern extruder screws feature specialized zones for different processing stages:

- Feed zone optimization for consistent material intake

- Compression zone engineering for optimal mixing

- Metering zone precision for uniform output

- Barrier screw technology for enhanced mixing

- Multi-stage compression for complex formulations

Each zone serves a specific purpose in the extrusion process. The design must match the specific rubber compound being processed.

Temperature Control Systems

Precision temperature control is essential for consistent product quality. Modern extruders use multiple heating and cooling zones.

Advanced systems monitor temperature at dozens of points throughout the process. Computer-controlled systems maintain temperatures within extremely tight tolerances.

Some systems use induction heating for rapid temperature changes. This technology provides more responsive control than traditional heating methods.

Pressure Monitoring and Control

Pressure control prevents defects and ensures consistent product dimensions. Modern systems monitor pressure at multiple points in the process.

Automatic pressure relief systems protect equipment and maintain product quality. These systems respond faster than human operators could manually.

Pressure data helps optimize processing parameters for different rubber compounds. This information is stored and used for future production runs.

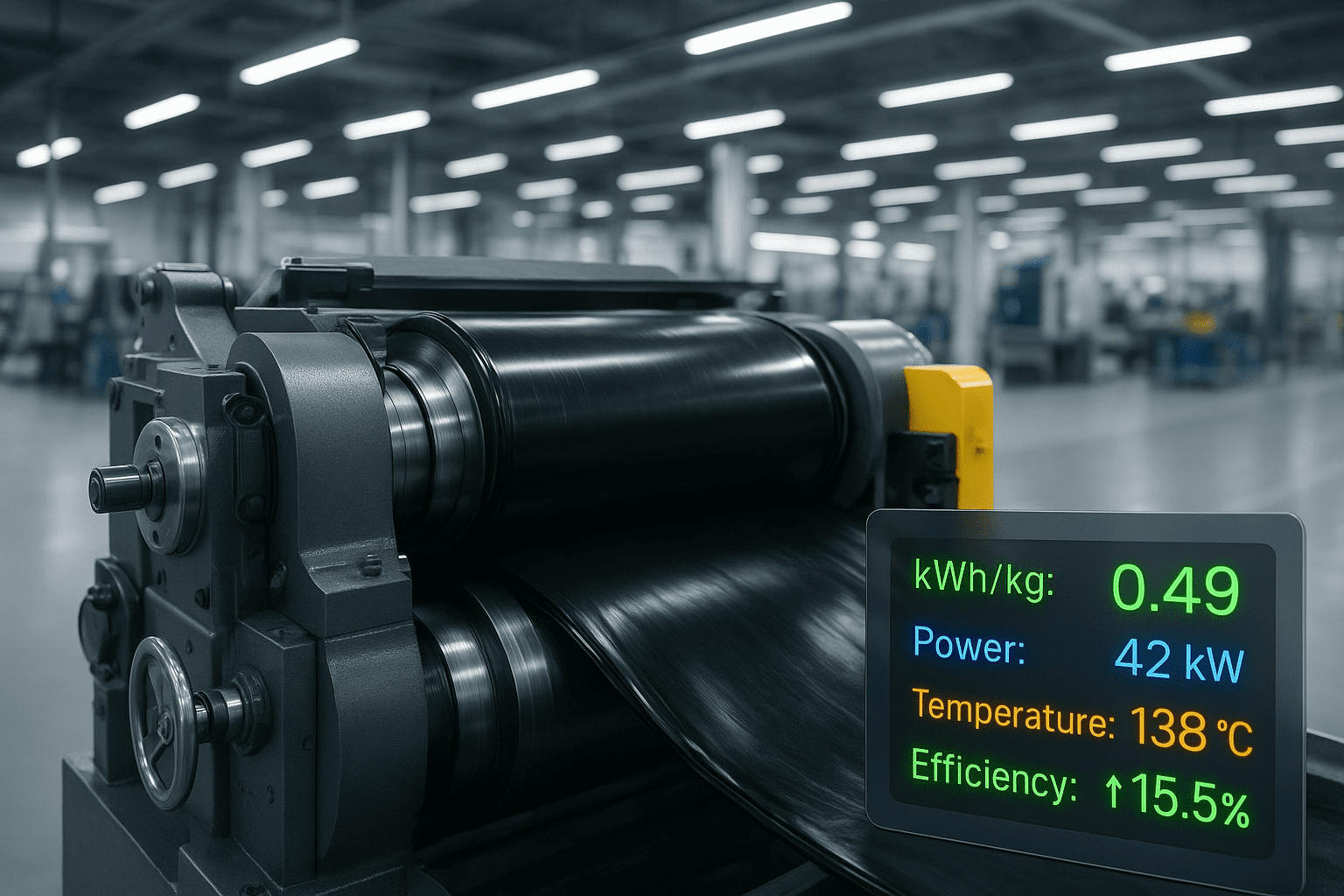

Energy-Saving Extrusion Technology: Sustainable Manufacturing

Energy-saving extrusion technology addresses both cost concerns and environmental responsibility. These systems reduce energy consumption while maintaining or improving product quality.

Modern extruders incorporate several energy-saving features. These technologies can reduce energy consumption by 20-40% compared to older systems.

Advanced Motor Control Systems

Variable frequency drives optimize motor performance throughout the production cycle. These systems adjust motor speed based on actual processing requirements.

Servo motors provide precise control with lower energy consumption. They operate only when needed, unlike continuous-run systems.

Regenerative braking systems capture energy during deceleration. This energy is fed back into the electrical system for reuse.

Heat Recovery Systems

Heat recovery technology captures waste heat from the extrusion process. This recovered heat can be used for other manufacturing processes or facility heating.

Some systems use heat exchangers to preheat incoming materials. This reduces the energy required to reach processing temperatures.

Thermal insulation improvements reduce heat loss throughout the system. Better insulation means less energy required to maintain temperatures.

Process Optimization Software

Advanced software analyzes energy consumption patterns throughout the production process. This data identifies opportunities for energy savings.

Predictive algorithms optimize processing parameters for maximum efficiency. These systems learn from historical data to improve performance continuously.

Real-time monitoring helps operators identify and correct energy waste immediately. Quick corrections prevent extended periods of inefficient operation.

Discover the latest innovations in energy-efficient rubber extrusion technology: https://www.crownsmachinery.com/innovations-in-rubber-extrusion-technology/

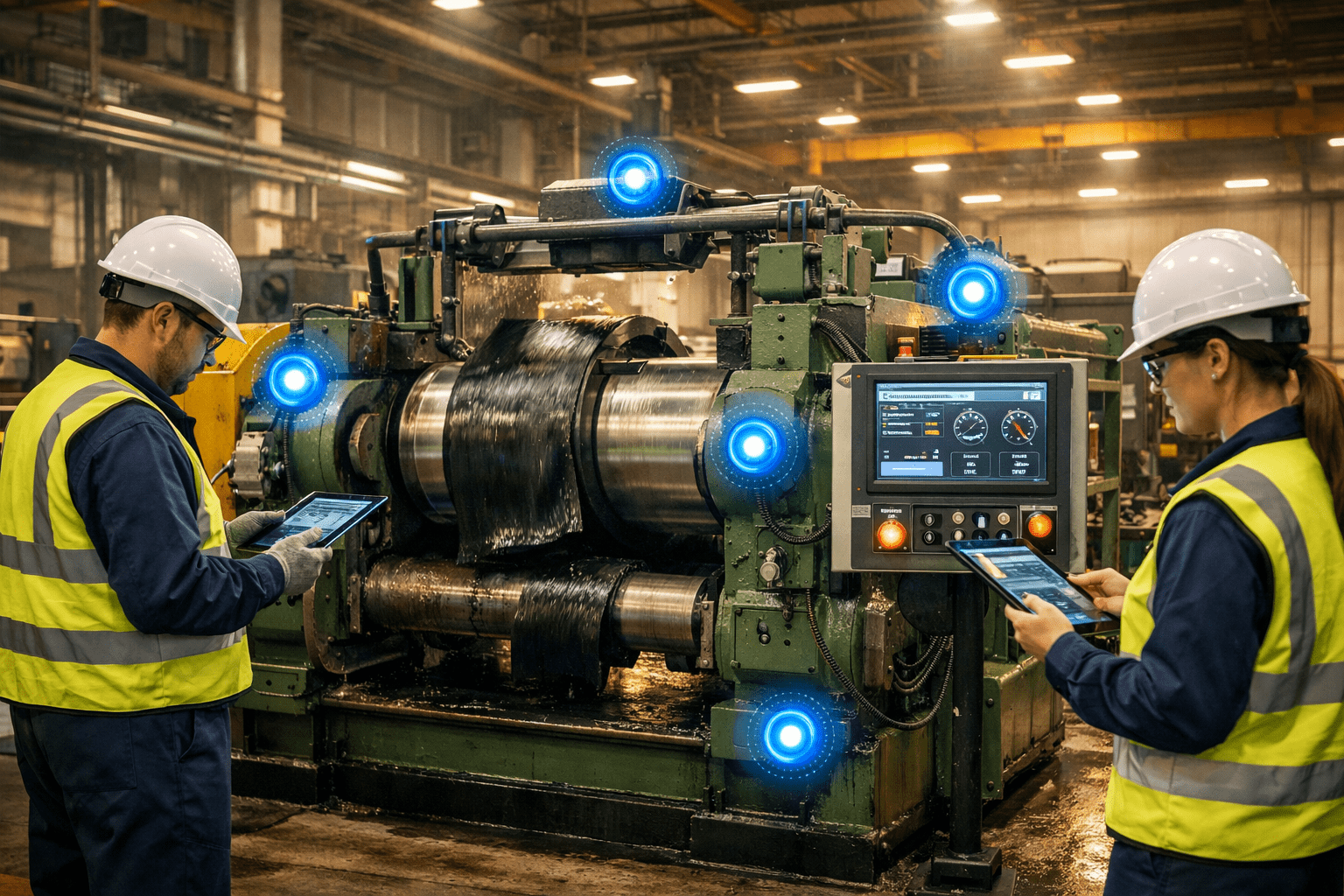

Automated Rubber Extrusion Lines: Maximizing Production Efficiency

Automated rubber extrusion lines represent the pinnacle of modern manufacturing technology. These systems integrate multiple processes into seamless production workflows.

Automation reduces labor costs while improving product consistency. Human operators focus on oversight and quality control rather than manual operations.

Integration of Multiple Processes

Modern automated lines combine extrusion with downstream processes:

- Automatic material handling from storage to extruder

- Integrated cooling systems for precise temperature control

- Automated cutting and sizing equipment

- Quality inspection systems with automatic reject handling

- Packaging and palletizing automation

This integration eliminates manual handling between processes. Reduced handling means fewer opportunities for contamination or damage.

Robotic Systems Integration

Industrial robots handle materials with precision and consistency. They can work in environments that would be challenging for human operators.

Robotic systems operate continuously without fatigue. This consistency improves product quality and reduces variation.

Programming flexibility allows robots to handle different products with minimal changeover time. Quick changeovers increase overall production efficiency.

Quality Control Automation

Automated quality control systems inspect products continuously during production. These systems detect defects that might be missed by visual inspection.

Machine vision systems measure dimensions with micron-level accuracy. They can detect subtle variations that affect product performance.

Automatic reject systems remove defective products without stopping production. This maintains the flow of good products while segregating defects.

Data Collection and Analysis

Automated systems collect vast amounts of production data. This information helps identify optimization opportunities and predict maintenance needs.

Statistical process control software analyzes trends in real-time. Operators receive alerts when processes drift from optimal parameters.

Production reports provide detailed information for quality audits and process improvements. This documentation supports continuous improvement efforts.

Innovations in Rubber Extrusion: Cutting-Edge Developments

Innovations in rubber extrusion continue to push the boundaries of what’s possible in rubber manufacturing. These developments address emerging market needs and technological capabilities.

Recent innovations focus on sustainability, precision, and versatility. Manufacturers seek solutions that provide competitive advantages in demanding markets.

Smart Manufacturing Integration

Industry 4.0 technologies are transforming rubber extrusion operations. Smart sensors and connected systems provide unprecedented visibility into production processes.

Internet of Things (IoT) devices monitor equipment health continuously. Predictive maintenance algorithms use this data to schedule maintenance before failures occur.

Cloud-based systems allow remote monitoring and control of extrusion lines. This capability enables expert support from anywhere in the world.

Advanced Material Processing

New rubber compounds require specialized processing techniques. Advanced extrusion systems adapt to handle these challenging materials.

Multi-component extrusion allows simultaneous processing of different materials. This capability enables complex product designs that weren’t previously possible.

Nano-material incorporation requires precise control to achieve uniform distribution. Advanced mixing systems ensure consistent properties throughout the product.

Additive Manufacturing Integration

Some manufacturers combine extrusion with additive manufacturing principles. This hybrid approach enables production of complex geometries and custom products.

3D printing technologies adapt to use extruded rubber as feedstock. This combination opens new possibilities for product design and customization.

On-demand production capabilities reduce inventory requirements. Manufacturers can produce products as needed rather than maintaining large inventories.

Environmental Sustainability Innovations

Green manufacturing initiatives drive innovation in extrusion technology. New systems minimize waste and reduce environmental impact.

Closed-loop recycling systems reprocess production waste into usable material. This approach reduces raw material consumption and waste disposal costs.

Bio-based rubber compounds require specialized processing parameters. Advanced systems adapt to handle these environmentally friendly materials.

Water-based processing systems eliminate or reduce solvent use. This change improves workplace safety and reduces environmental impact.

Read about recent innovations shaping the rubber industry: https://www.applerubber.com/hot-topics-for-engineers/recent-innovations-in-the-rubber-industry-2/

Selecting the Right Advanced Extrusion Technology

Choosing appropriate advanced extrusion technology requires careful consideration of multiple factors. The right system depends on specific production requirements and business objectives.

Production Volume Considerations

High-volume operations benefit from fully automated systems with maximum efficiency features. These systems provide the best return on investment for large-scale production.

Medium-volume operations might choose semi-automated systems that balance capability with cost. These systems provide many advanced features at lower initial investment.

Low-volume or specialty operations might focus on flexibility and quick changeover capabilities. These systems optimize for variety rather than maximum throughput.

Product Quality Requirements

Industries with strict quality standards require high-precision systems with comprehensive quality control. Medical and aerospace applications typically fall into this category.

General industrial applications might prioritize cost-effectiveness over maximum precision. These systems still provide good quality while controlling costs.

Consumer products often require a balance of quality and cost-effectiveness. The right system provides adequate quality at competitive prices.

Budget and ROI Analysis

Initial investment costs vary significantly between different technology levels. Buyers must balance capabilities with available budget.

Operating cost analysis includes energy consumption, maintenance, and labor requirements. Advanced systems often provide better long-term economics despite higher initial costs.

Payback period calculations help justify investment in advanced technology. Faster payback periods make investment decisions easier.

Future Expansion Plans

Scalable systems accommodate future production increases without complete replacement. Modular designs allow incremental capacity additions.

Technology upgrade paths ensure systems remain current as new innovations emerge. Future-proof designs protect long-term investments.

Flexibility for new products prevents obsolescence as market demands change. Adaptable systems provide better long-term value.

Implementation Best Practices for Advanced Systems

Successful implementation of advanced rubber extrusion technology requires careful planning and execution. Following proven best practices maximizes the benefits of new technology.

Project Planning and Timeline

Comprehensive project planning prevents delays and cost overruns. Detailed timelines coordinate all aspects of implementation.

Stakeholder involvement ensures all requirements are considered. Production, quality, maintenance, and management input improves project outcomes.

Contingency planning addresses potential challenges before they become problems. Backup plans minimize disruption to ongoing operations.

Training and Workforce Development

Operator training ensures effective use of new technology. Comprehensive training programs cover both operation and troubleshooting.

Maintenance staff require specialized training for advanced systems. Proper maintenance preserves equipment performance and longevity.

Management training helps leaders understand new capabilities and optimize utilization. Leadership support is essential for successful implementation.

Integration with Existing Operations

Seamless integration minimizes disruption to ongoing production. Careful planning coordinates new systems with existing operations.

Data system integration provides comprehensive visibility across all operations. Unified reporting improves decision-making capabilities.

Quality system updates ensure new processes meet existing standards. Documentation updates maintain compliance with industry requirements.

Performance Monitoring and Optimization

Continuous monitoring identifies opportunities for improvement. Regular performance reviews ensure systems meet expectations.

Benchmarking against industry standards reveals competitive position. This information guides future improvement efforts.

Feedback loops incorporate operator experience into system optimization. Practical knowledge improves theoretical system designs.

Future Trends in Advanced Rubber Extrusion

The rubber extrusion industry continues evolving with new technologies and market demands. Understanding future trends helps manufacturers prepare for upcoming changes.

Artificial Intelligence Integration

AI-powered systems will provide unprecedented process optimization capabilities. Machine learning algorithms will continuously improve performance without human intervention.

Predictive analytics will anticipate quality issues before they occur. This capability will virtually eliminate defective products.

Automated problem-solving will reduce downtime and improve efficiency. AI systems will diagnose and correct issues faster than human operators.

Sustainability Focus

Environmental regulations will drive adoption of greener technologies. Manufacturers will prioritize systems that reduce environmental impact.

Circular economy principles will influence system design. Recycling and reuse capabilities will become standard features.

Energy efficiency will become even more important as energy costs rise. Advanced systems will incorporate more energy-saving technologies.

Customization and Flexibility

Market demands for customized products will require more flexible systems. Quick changeover capabilities will become essential.

Small batch production will increase in importance. Systems must handle diverse products efficiently.

On-demand manufacturing will reduce inventory requirements. Flexible systems will enable just-in-time production strategies.

Conclusion: Embracing Advanced Rubber Extrusion Technology

Advanced rubber extrusion techniques represent the future of rubber manufacturing. These technologies provide significant advantages in quality, efficiency, and sustainability.

Manufacturers who embrace these innovations position themselves for long-term success. The benefits include improved product quality, reduced costs, and enhanced competitiveness.

Investment in advanced technology requires careful planning and execution. However, the long-term benefits justify the initial investment for most operations.

The rubber extrusion industry will continue evolving with new innovations and capabilities. Staying current with these developments ensures continued competitiveness in demanding markets.

Stay informed about UK rubber extrusion industry trends and developments: https://www.nufox.com/news/rubber-extrusions-in-the-uk-industry-overview-and-trends

Companies that adopt advanced rubber extrusion technology today will lead the industry tomorrow. The time to embrace these innovations is now.