Are you searching for the perfect rubber hydraulic press machine for your manufacturing needs? Finding the right rubber hydraulic press machine can make or break your production efficiency and product quality. This comprehensive guide will help you navigate the complex world of rubber molding equipment and make an informed purchasing decision.

What is a Rubber Hydraulic Press Machine?

A rubber hydraulic press machine is specialized industrial equipment designed for molding and shaping rubber materials through controlled pressure and heat. These powerful machines use hydraulic systems to apply precise force, compressing rubber compounds into desired shapes and forms.

The hydraulic system provides consistent pressure distribution across the mold surface. This ensures uniform compression and prevents defects in the final rubber products. Modern rubber hydraulic presses can handle pressures ranging from 50 tons to over 1000 tons, depending on the application requirements.

Key components include the hydraulic cylinder, heating platens, control system, and safety mechanisms. The heating platens maintain optimal temperature for rubber vulcanization, while the control system manages pressure, temperature, and timing parameters.

Types of Rubber Hydraulic Press Machines

Compression Molding Press for Rubber

Compression molding presses are the most common type for rubber manufacturing. These machines work by placing pre-measured rubber material into a heated mold cavity. The press then applies pressure to compress the material and fill the mold completely.

Key Features:

- Direct compression method

- Excellent for solid rubber parts

- High production efficiency

- Minimal material waste

- Suitable for thick-walled products

Compression molding presses excel at producing gaskets, seals, automotive parts, and industrial rubber components. They offer superior control over material flow and density distribution.

Transfer Molding Presses

Transfer molding presses use a different approach where rubber material is heated in a separate chamber before being forced into the mold cavity. This method provides better flow characteristics for complex shapes.

Applications:

- Intricate rubber parts

- Multi-cavity molding

- Insert molding applications

- Precision components

- Electronic rubber parts

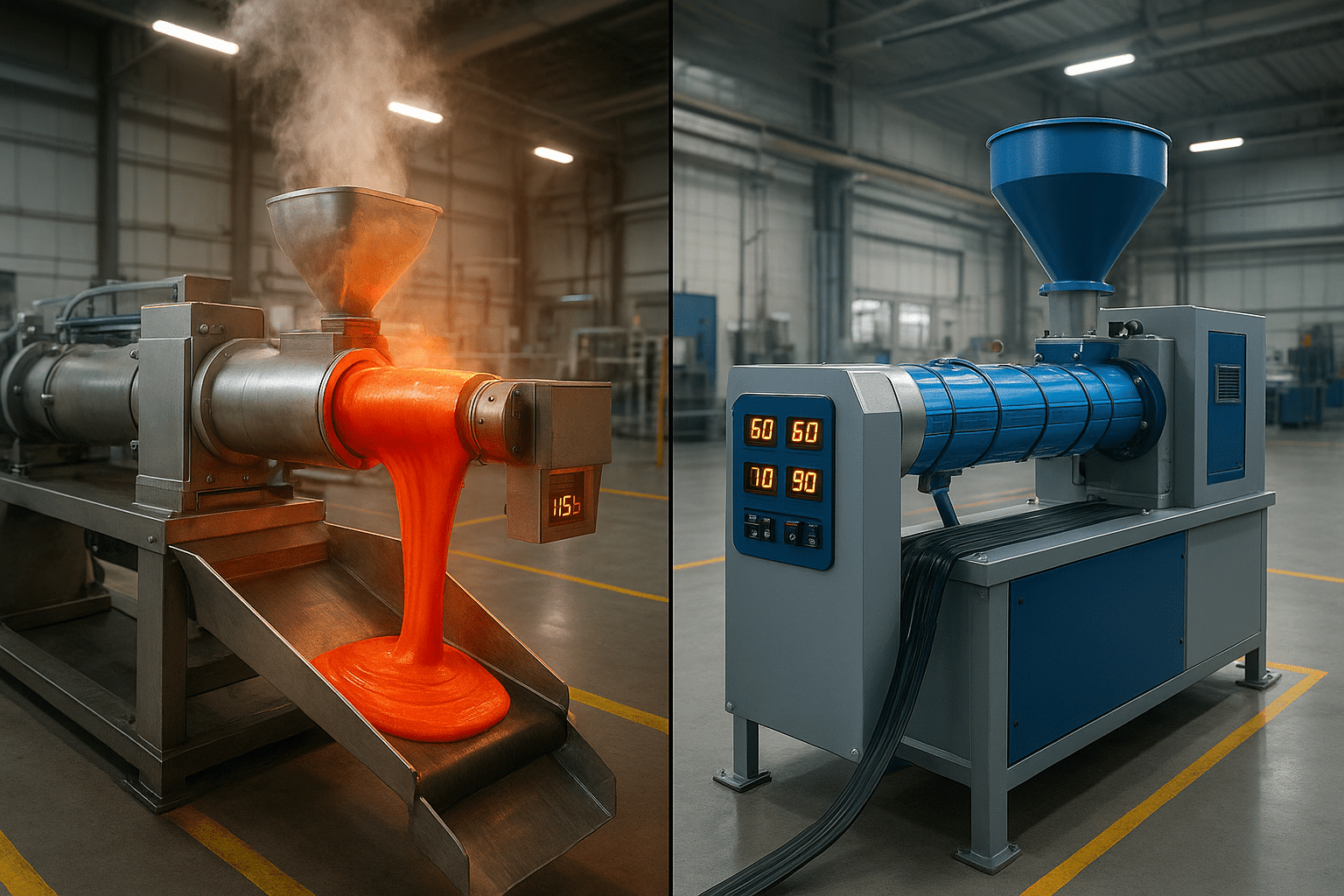

Injection Molding Presses

Injection molding presses for rubber combine the benefits of plastic injection molding with rubber processing. These machines inject heated rubber material directly into closed molds under high pressure.

Advantages:

- Faster cycle times

- Reduced flash and waste

- Better dimensional accuracy

- Automated operation

- High-volume production capability

Automatic Rubber Press Machine Manufacturers

Leading Global Manufacturers

Wabash MPI Wabash MPI stands as one of the premier automatic rubber press machine manufacturers worldwide. Their hydraulic presses feature advanced control systems and energy-efficient designs. The company offers machines ranging from 50 to 4000 tons capacity. Visit Wabash MPI’s official website for detailed specifications and case studies.

French Oil Mill Machinery French Oil Mill Machinery produces robust hydraulic presses specifically designed for rubber molding applications. Their machines incorporate precision heating systems and programmable logic controllers for consistent results.

Macrodyne Technologies Macrodyne specializes in custom hydraulic press solutions for rubber manufacturing. Their automatic systems include features like servo-hydraulic control, real-time monitoring, and predictive maintenance capabilities.

Beckwood Press Beckwood Press offers innovative rubber molding solutions with their hydraulic press technology. Their machines feature quick mold change systems and advanced safety features for operator protection.

What to Look for in Manufacturers

Quality Certifications Reputable manufacturers maintain ISO 9001 quality management systems and comply with international safety standards. Look for CE marking on European machines and UL listing for North American equipment.

Technical Support Choose manufacturers that provide comprehensive technical support including installation, training, and ongoing maintenance services. Local service availability is crucial for minimizing downtime.

Customization Capabilities The best manufacturers offer customization options to meet specific production requirements. This includes custom platen sizes, specialized heating systems, and integrated automation features.

Best Rubber Molding Press Machine Features

Hydraulic System Excellence

The hydraulic system forms the heart of any quality rubber molding press machine. Premium machines use servo-hydraulic technology for precise pressure control and energy efficiency.

Critical Hydraulic Components:

- Variable displacement pumps

- Proportional valves

- Pressure accumulators

- Filtration systems

- Temperature control units

Advanced hydraulic systems provide pressure accuracy within ±1% and maintain consistent force throughout the molding cycle. This precision ensures uniform part quality and reduces material waste.

Temperature Control Systems

Precise temperature control is essential for proper rubber vulcanization. The best rubber molding press machines feature multi-zone heating systems with independent temperature control for each platen.

Temperature Control Features:

- Digital temperature controllers

- Thermocouple feedback systems

- Uniform heat distribution

- Fast heating and cooling cycles

- Energy-efficient insulation

Modern systems can maintain temperature stability within ±2°C, ensuring consistent cure rates and optimal rubber properties.

Safety and Automation Features

Safety Systems:

- Light curtains and safety mats

- Emergency stop mechanisms

- Pressure relief valves

- Dual-palm controls

- Mold protection systems

Automation Features:

- PLC-based control systems

- Recipe management

- Data logging capabilities

- Remote monitoring options

- Automatic mold changing

Custom Rubber Hydraulic Press Solutions

Why Choose Custom Solutions?

Standard rubber hydraulic presses may not meet every production requirement. Custom solutions address specific challenges in rubber manufacturing processes.

Custom Design Benefits:

- Optimized for specific rubber compounds

- Tailored platen configurations

- Specialized heating patterns

- Integration with existing production lines

- Enhanced productivity features

Common Customization Options

Platen Modifications Custom platen sizes and configurations accommodate unique mold requirements. Options include oversized platens, T-slot configurations, and specialized heating patterns.

Automation Integration Custom automation packages can include robotic material handling, automatic demolding systems, and quality inspection equipment.

Specialized Controls Advanced control systems can be customized for specific rubber compounds and curing requirements. This includes pressure profiling, temperature ramping, and cycle optimization features.

Rubber Hydraulic Press Machine for Sale: Buying Guide

Determining Your Requirements

Production Volume Assessment Calculate your daily, weekly, and monthly production requirements. This determines the necessary cycle time and overall machine capacity.

Consider future growth projections when sizing your equipment. Investing in slightly larger capacity can accommodate business expansion without requiring new equipment purchases.

Part Specifications Analysis Analyze your rubber parts for size, complexity, and material requirements. This information guides machine selection and feature requirements.

Material Considerations Different rubber compounds have varying processing requirements. Natural rubber, synthetic rubber, and specialty compounds may need different temperature and pressure profiles. The American Chemical Society Rubber Division provides comprehensive resources on rubber chemistry and processing parameters.

Key Specifications to Consider

Pressure Capacity Choose machines with 20-30% more pressure capacity than your calculated requirements. This provides safety margin and accommodates material variations.

Platen Size Platen dimensions must accommodate your largest molds with adequate clearance. Consider multiple-cavity molds for higher production efficiency.

Daylight Opening Ensure sufficient daylight opening for mold installation and part removal. This measurement affects both mold design flexibility and operational efficiency.

Heating Capacity Heating systems must provide adequate temperature for your rubber compounds. Consider heating rate, maximum temperature, and temperature uniformity requirements.

New vs. Used Equipment

New Equipment Advantages:

- Latest technology and features

- Full warranty coverage

- Technical support included

- Customization options available

- Energy efficiency improvements

Used Equipment Considerations:

- Lower initial investment

- Immediate availability

- Proven performance history

- Limited customization options

- Potential maintenance costs

Financing Options

Equipment Leasing Leasing arrangements preserve working capital while providing access to modern equipment. Many manufacturers offer attractive lease terms with purchase options.

Equipment Loans Traditional equipment financing allows ownership while spreading payments over several years. Interest rates vary based on creditworthiness and loan terms.

Rent-to-Own Programs Some suppliers offer rent-to-own arrangements that provide flexibility for growing businesses. These programs often include maintenance and service packages.

Installation and Setup Considerations

Site Preparation Requirements

Foundation Specifications Rubber hydraulic presses require solid foundations to absorb operating forces and minimize vibrations. Foundation design depends on machine size and operating pressure.

Concrete foundations should cure for minimum 28 days before equipment installation. Anchor bolt locations must be precisely positioned according to manufacturer specifications.

Utility Requirements Electrical power requirements vary by machine size and features. Most machines require 440V three-phase power with appropriate amperage capacity.

Compressed air systems support pneumatic controls and automation features. Water cooling may be required for hydraulic systems and temperature control.

Space Planning Allow adequate space around the machine for operation, maintenance, and material handling. Consider overhead crane access for mold changes and maintenance activities.

Training and Support

Operator Training Programs Comprehensive operator training ensures safe and efficient machine operation. Training should cover normal operations, safety procedures, and basic troubleshooting. The Occupational Safety and Health Administration provides safety training requirements for industrial equipment operators.

Maintenance Training Maintenance personnel need specialized training on hydraulic systems, electrical controls, and heating systems. Proper maintenance prevents costly breakdowns and extends equipment life.

Technical Documentation Complete technical documentation includes operating manuals, maintenance schedules, spare parts lists, and electrical schematics. Digital documentation provides easy access and updates.

Maintenance and Optimization

Preventive Maintenance Programs

Daily Maintenance Tasks:

- Check hydraulic fluid levels

- Inspect safety systems

- Monitor temperature readings

- Clean work areas

- Document production parameters

Weekly Maintenance:

- Filter inspections

- Lubrication schedules

- Electrical connection checks

- Calibration verifications

- Performance data analysis

Monthly Maintenance:

- Hydraulic system analysis

- Heating system inspection

- Control system diagnostics

- Wear component evaluation

- Efficiency assessments

Performance Optimization

Cycle Time Reduction Optimize heating and cooling cycles through improved temperature control and material handling procedures. Faster cycles increase production capacity without compromising quality.

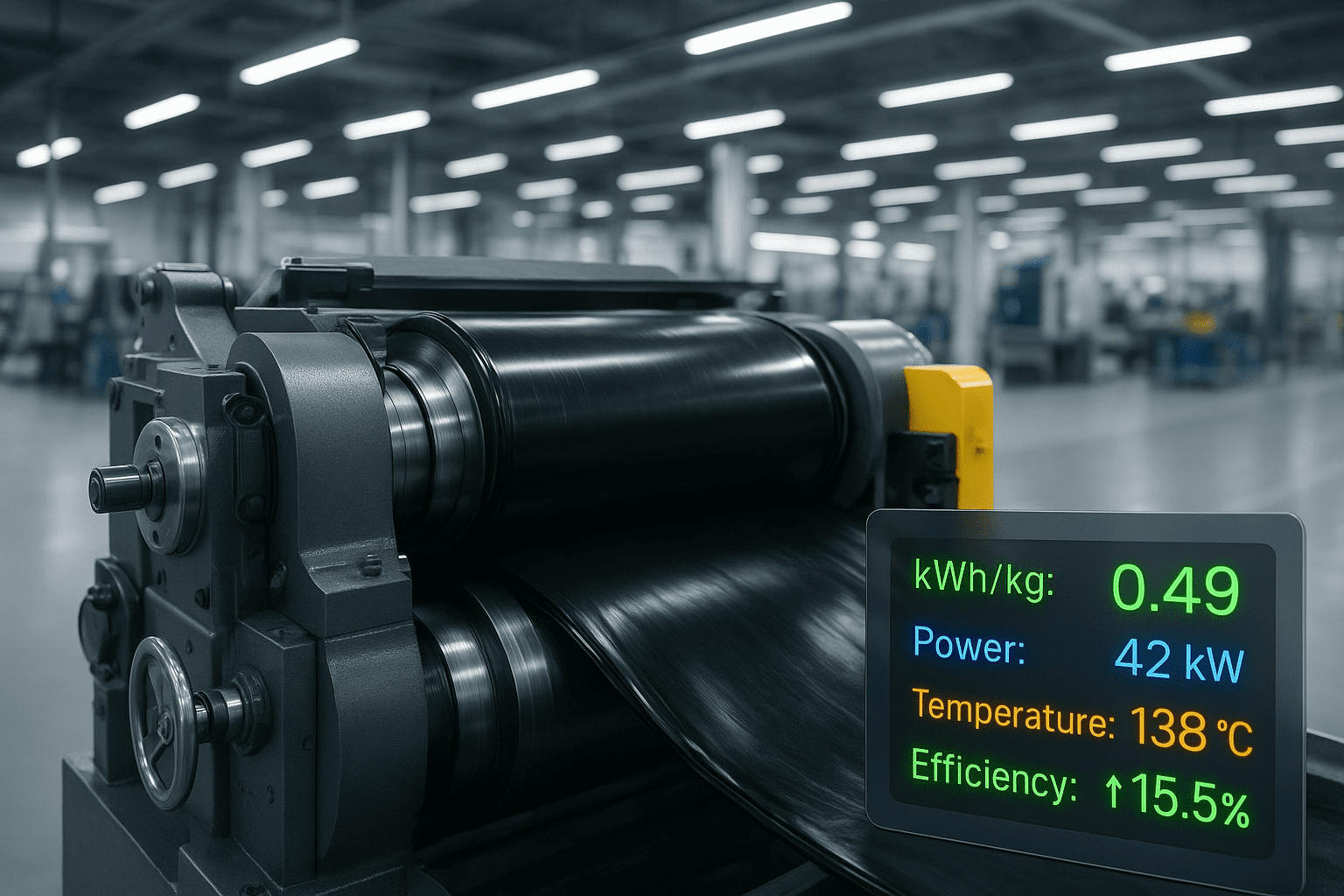

Energy Efficiency Improvements Modern servo-hydraulic systems reduce energy consumption by 30-50% compared to conventional systems. Upgrading older machines can provide significant operational savings.

Quality Improvements Regular calibration and maintenance ensure consistent part quality. Statistical process control helps identify trends and prevent quality issues.

Cost Analysis and ROI Calculations

Total Cost of Ownership

Initial Investment Costs:

- Equipment purchase price

- Installation and setup costs

- Training expenses

- Initial spare parts inventory

- Site preparation requirements

Operating Costs:

- Electrical power consumption

- Hydraulic fluid and maintenance

- Replacement parts and wear items

- Labor costs

- Insurance and financing costs

Return on Investment Factors

Production Efficiency Gains Modern equipment typically increases production efficiency by 15-25% through faster cycle times and reduced downtime. Calculate annual production increases and associated revenue gains.

Quality Improvements Better temperature and pressure control reduce scrap rates and customer returns. Quality improvements enhance customer satisfaction and reduce warranty costs.

Maintenance Cost Reductions New equipment reduces maintenance costs and unplanned downtime. Reliability improvements contribute significantly to overall cost savings.

Future Trends in Rubber Hydraulic Press Technology

Industry 4.0 Integration

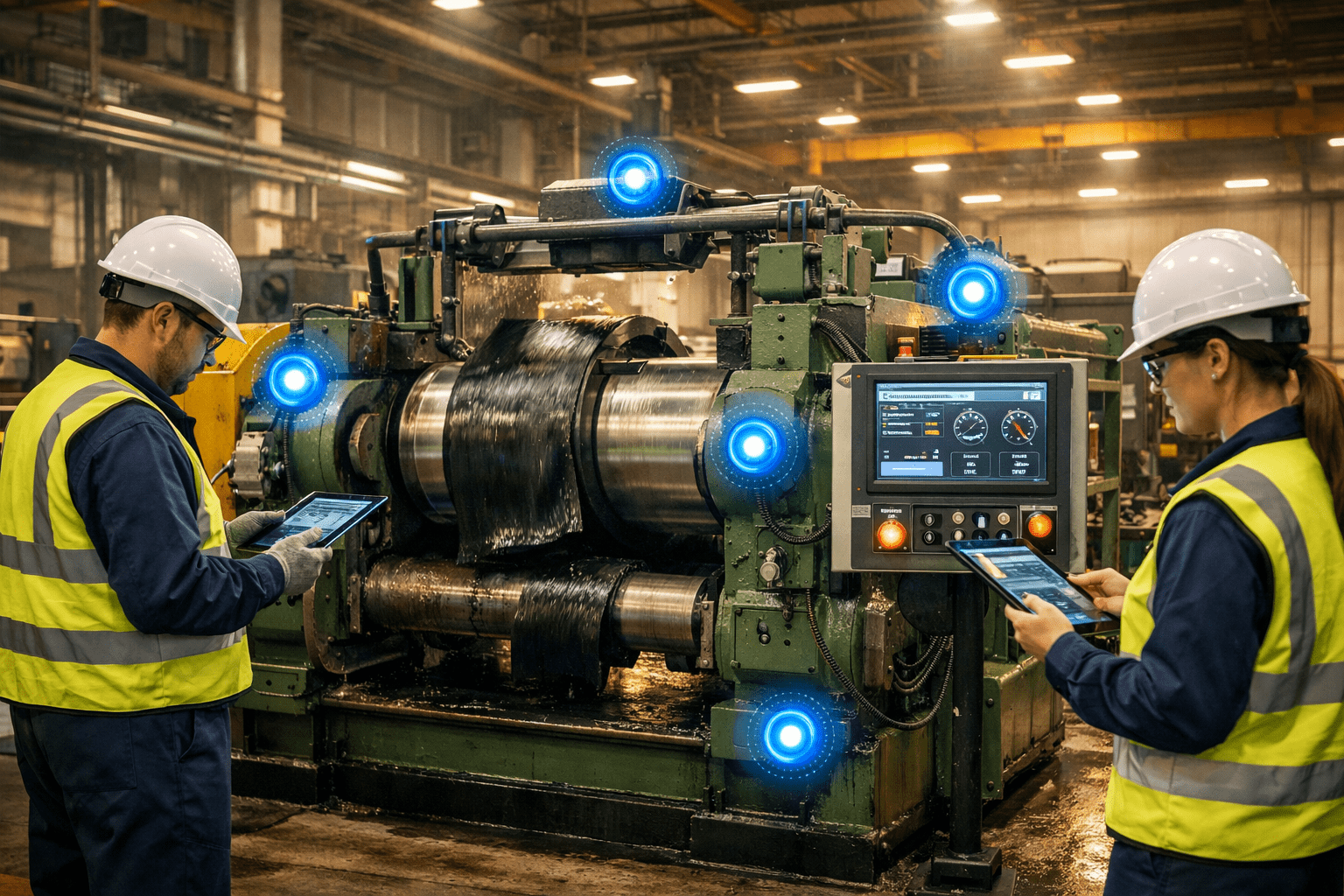

Smart Manufacturing Features Modern rubber hydraulic presses incorporate IoT connectivity for real-time monitoring and predictive maintenance. Data analytics help optimize production parameters and prevent equipment failures. The Industrial Internet Consortium leads Industry 4.0 standardization efforts for manufacturing equipment.

Remote Monitoring Systems Cloud-based monitoring systems allow manufacturers to track equipment performance from anywhere. Remote diagnostics reduce service response times and improve troubleshooting efficiency.

Environmental Considerations

Energy Efficiency Improvements New hydraulic technologies reduce energy consumption while maintaining performance. Servo-hydraulic systems and variable frequency drives contribute to sustainability goals.

Emission Reduction Technologies Advanced ventilation systems and enclosed processes minimize emissions from rubber processing operations. Environmental compliance becomes increasingly important for manufacturers.

Advanced Materials Processing

Multi-Material Capabilities Future machines will handle diverse rubber compounds and composite materials in single operations. Flexibility accommodates changing market demands and product innovations.

Precision Processing Technologies Enhanced control systems enable processing of advanced rubber materials with tighter tolerances and improved properties. This supports development of high-performance applications.

Conclusion

Selecting the right rubber hydraulic press machine requires careful consideration of your specific production requirements, quality standards, and budget constraints. The best rubber molding press machine combines reliable hydraulic systems, precise temperature control, and comprehensive safety features.

Whether you need a compression molding press for rubber or a fully automatic system, working with reputable manufacturers ensures access to quality equipment and ongoing support. Custom rubber hydraulic press solutions provide the flexibility to meet unique production challenges while maintaining operational efficiency.

Consider total cost of ownership when evaluating rubber hydraulic press machines for sale. While initial investment is important, long-term operating costs and productivity gains significantly impact overall profitability. For comprehensive equipment selection guidance, explore our Manufacturing Equipment Selection Guide.

The rubber processing industry continues evolving with advanced technologies and sustainable practices. Investing in modern hydraulic press equipment positions your business for future growth and competitiveness in the global marketplace. Industry insights and market trends are available through the Rubber Manufacturers Association.

Take time to thoroughly evaluate your options, visit manufacturer facilities, and speak with existing customers before making your final decision. The right rubber hydraulic press machine will serve your business reliably for many years while delivering consistent quality and productivity.