Sustainable rubber manufacturing is transforming the industry through eco-friendly processes and green technologies. Modern manufacturers are adopting sustainable rubber processing methods to reduce environmental impact while maintaining product quality. This shift toward sustainable rubber manufacturing creates both environmental benefits and business advantages.

The rubber industry faces increasing pressure to reduce its carbon footprint and adopt cleaner production methods. Sustainable rubber processing addresses these challenges through innovative technologies and improved manufacturing practices.

This comprehensive guide explores sustainable rubber manufacturing approaches, energy-efficient equipment, and recycling technologies that shape the future of rubber production.

Understanding Sustainable Rubber Processing

Sustainable rubber processing involves manufacturing methods that minimize environmental impact throughout the production cycle. These approaches reduce waste, conserve energy, and use eco-friendly materials while maintaining product quality standards.

Traditional rubber manufacturing often creates significant environmental challenges. Sustainable rubber processing addresses these issues through innovative technologies and improved operational practices.

Key Principles of Sustainable Manufacturing

Resource Conservation Sustainable rubber processing focuses on minimizing raw material consumption and maximizing material utilization. Efficient processes reduce waste generation and optimize resource usage.

Energy Efficiency Modern sustainable rubber processing systems consume less energy through improved equipment design and process optimization. Energy-efficient operations reduce both costs and environmental impact.

Waste Reduction Sustainable manufacturing minimizes waste generation through better process control and material recovery systems. Waste reduction strategies include recycling, reuse, and process optimization.

Cleaner Production Methods Sustainable rubber processing uses cleaner technologies that reduce emissions and environmental contamination. These methods protect air, water, and soil quality.

Environmental Benefits of Sustainable Approaches

Reduced Carbon Emissions Sustainable rubber processing significantly reduces greenhouse gas emissions through energy efficiency and cleaner technologies. Lower emissions help combat climate change.

Water Conservation Advanced sustainable rubber processing systems minimize water usage and improve water treatment. Better water management protects this precious resource.

Air Quality Improvement Cleaner production methods reduce air pollutant emissions. Improved air quality benefits both workers and surrounding communities.

Soil Protection Sustainable rubber processing prevents soil contamination through better waste management and chemical handling practices.

Energy-Efficient Rubber Machinery for Green Manufacturing

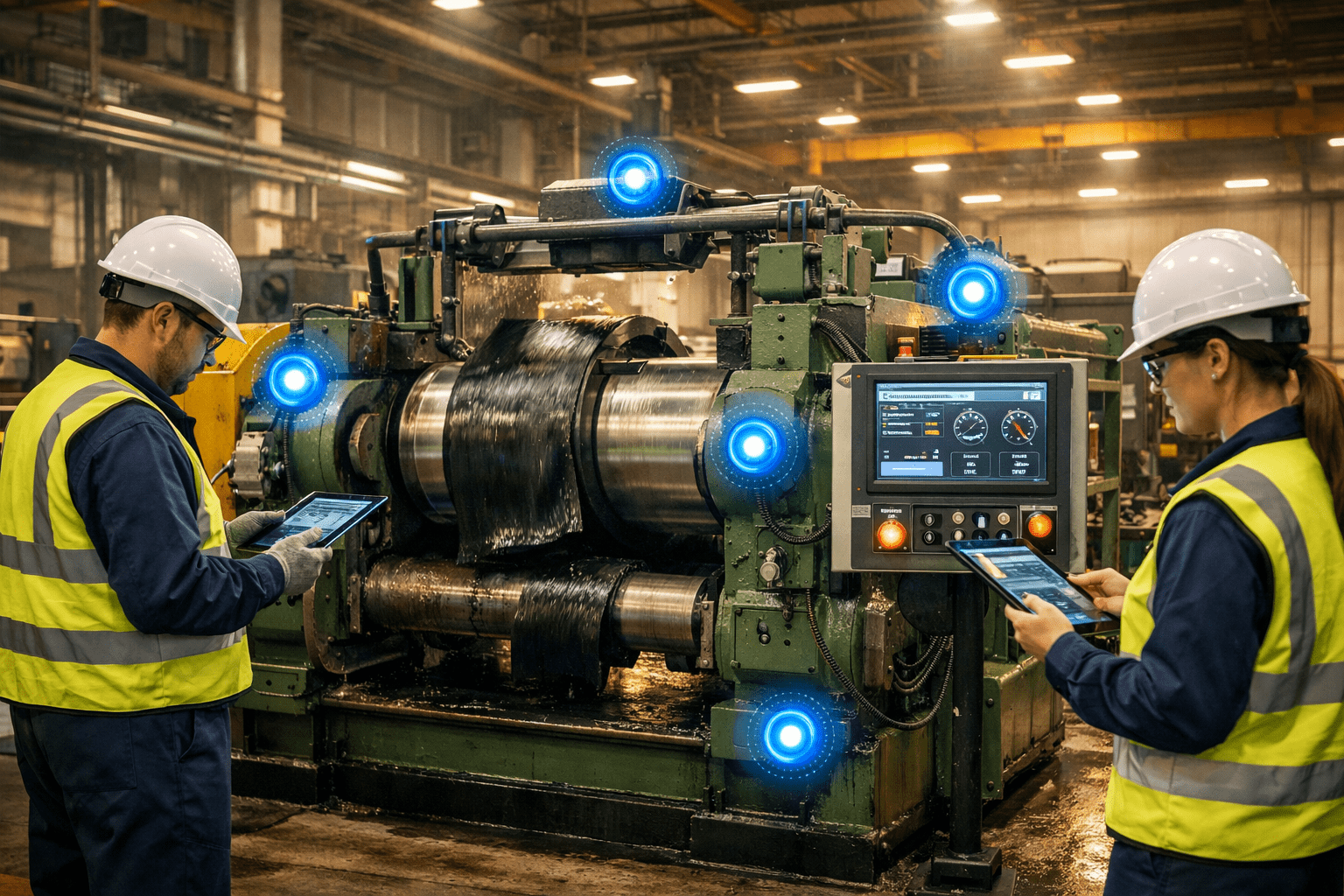

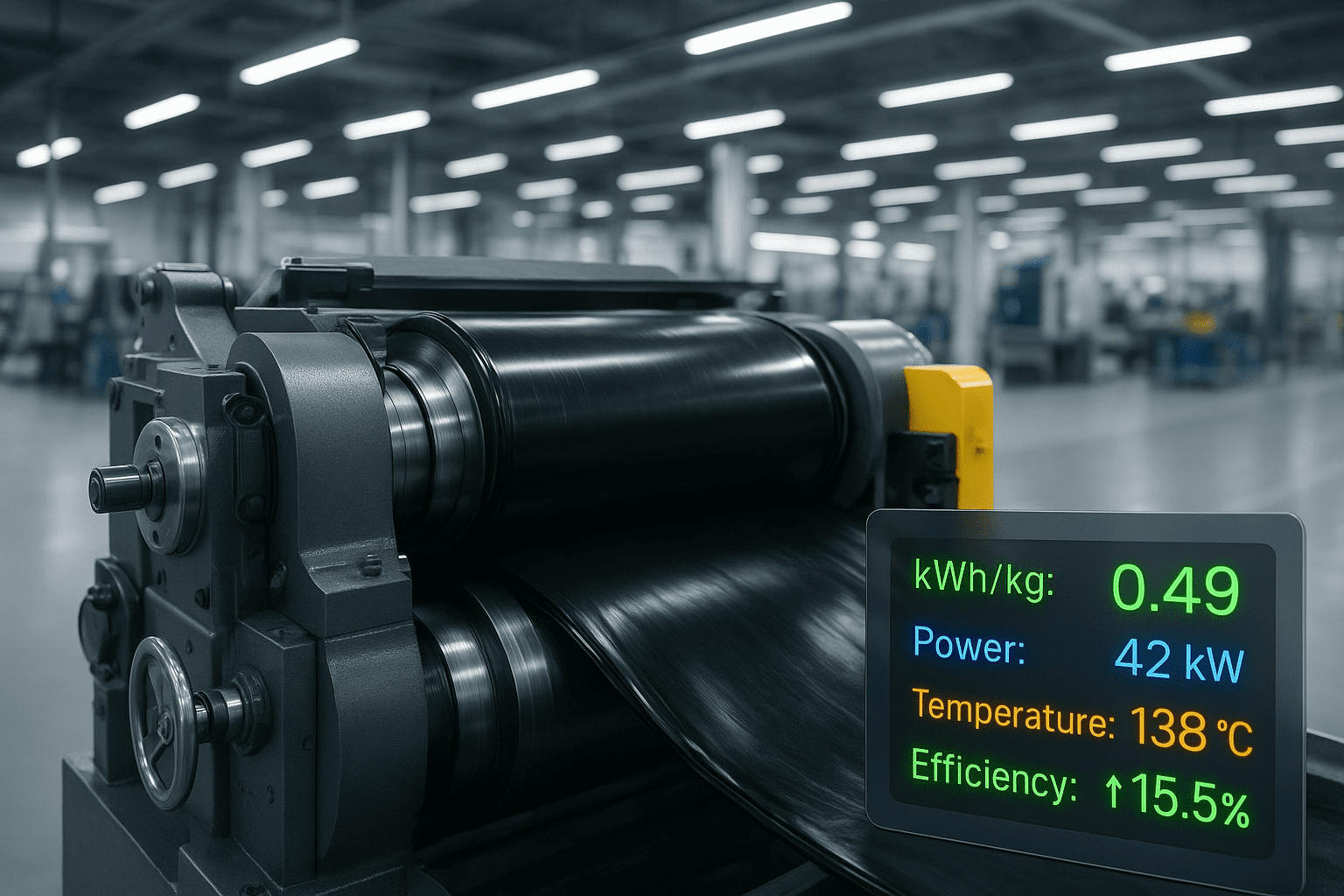

Energy-efficient rubber machinery represents a cornerstone of sustainable manufacturing. These advanced systems reduce power consumption while maintaining or improving production performance. Energy-efficient rubber machinery delivers significant cost savings and environmental benefits.

Modern energy-efficient rubber machinery incorporates advanced technologies that optimize power usage throughout the manufacturing process. These systems help manufacturers meet sustainability goals while improving profitability.

Advanced Motor Technologies

Variable Frequency Drives (VFDs) Energy-efficient rubber machinery uses VFDs to control motor speeds precisely. These systems adjust power consumption based on actual load requirements, reducing energy waste significantly.

VFDs in rubber processing equipment can reduce energy consumption by 20-50% compared to traditional fixed-speed systems. This technology pays for itself through energy savings within 1-2 years.

High-Efficiency Motors Premium efficiency motors in rubber machinery consume 15-25% less energy than standard motors. These motors generate less heat and require less cooling, further reducing energy needs.

Servo Motor Integration Servo motors provide precise control with excellent energy efficiency. Energy-efficient rubber machinery uses servo systems for applications requiring accurate positioning and speed control.

Heat Recovery Systems

Waste Heat Capture Energy-efficient rubber machinery captures waste heat from processing operations for reuse. Heat recovery systems can reclaim 30-60% of waste thermal energy.

Steam Generation Systems Captured waste heat generates steam for other processes or facility heating. This integrated approach maximizes energy utilization across manufacturing operations.

Hot Water Production Heat recovery systems produce hot water for cleaning, heating, and other facility needs. This reduces demand on primary heating systems.

Smart Power Management

Load Monitoring Systems Energy-efficient rubber machinery continuously monitors power consumption and identifies optimization opportunities. Smart systems automatically adjust operations to minimize energy usage.

Peak Demand Management Intelligent power management systems avoid peak demand charges by scheduling energy-intensive operations during off-peak periods. This can reduce electricity costs by 15-30%.

Power Factor Correction Advanced electrical systems maintain optimal power factor to minimize reactive power consumption. Improved power factor reduces utility charges and improves system efficiency.

Eco-Friendly Rubber Manufacturing Technologies

Eco-friendly rubber manufacturing technologies focus on reducing environmental impact through cleaner processes and sustainable materials. These innovative approaches transform traditional manufacturing methods to create more sustainable operations.

Modern eco-friendly rubber manufacturing integrates multiple technologies that work together to minimize environmental impact. These systems address air emissions, water usage, waste generation, and energy consumption.

Bio-Based Raw Materials

Natural Rubber Alternatives Eco-friendly rubber manufacturing increasingly uses bio-based materials derived from sustainable sources. Dandelion rubber, guayule, and other plant-based alternatives reduce dependence on traditional rubber trees.

Renewable Additives Sustainable manufacturing uses bio-based additives instead of petroleum-derived chemicals. These renewable materials reduce environmental impact while maintaining product performance.

Biodegradable Components Eco-friendly rubber manufacturing incorporates biodegradable materials that break down naturally at end-of-life. This reduces long-term environmental impact.

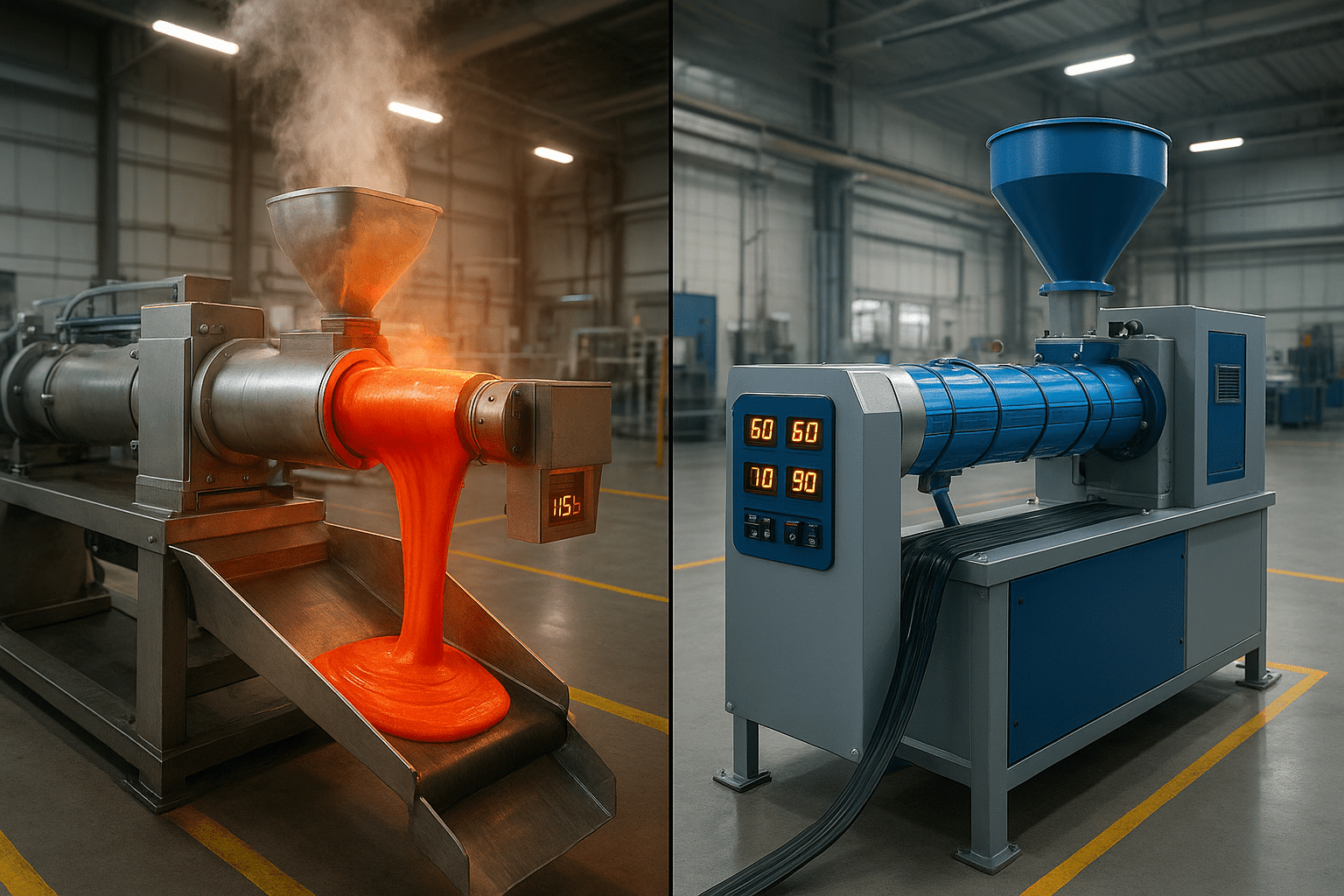

Clean Production Processes

Solvent-Free Processing Eco-friendly rubber manufacturing eliminates or minimizes solvent usage through advanced processing techniques. Water-based and solvent-free systems reduce air emissions and worker exposure.

Low-Temperature Curing Advanced curing technologies operate at lower temperatures, reducing energy consumption and emissions. Microwave curing and other innovative methods achieve excellent results with less environmental impact.

Closed-Loop Water Systems Eco-friendly rubber manufacturing uses closed-loop water systems that recycle and reuse process water. These systems minimize water consumption and eliminate wastewater discharge.

Emission Control Technologies

Air Pollution Control Systems Advanced filtration and scrubbing systems remove pollutants from process emissions. These technologies ensure compliance with environmental regulations while protecting air quality.

Volatile Organic Compound (VOC) Control Eco-friendly rubber manufacturing uses thermal oxidizers and other technologies to destroy VOCs before emission. This prevents harmful chemicals from entering the atmosphere.

Odor Control Systems Biological and chemical odor control systems eliminate unpleasant smells from rubber processing operations. This improves community relations and worker comfort.

Green Rubber Production Technologies

Green rubber production technologies encompass comprehensive approaches to sustainable manufacturing. These systems integrate multiple environmental technologies to create truly sustainable production operations.

Green rubber production technologies go beyond individual improvements to create holistic sustainable manufacturing systems. These approaches consider the entire production lifecycle from raw materials to finished products.

Integrated Environmental Management

Life Cycle Assessment (LCA) Green rubber production technologies use LCA to evaluate environmental impact throughout the product lifecycle. This comprehensive approach identifies improvement opportunities across all production stages.

Environmental Management Systems (EMS) Formal EMS frameworks help manufacturers implement and maintain green rubber production technologies. These systems ensure continuous improvement in environmental performance.

Carbon Footprint Reduction Green production technologies systematically reduce carbon emissions through energy efficiency, renewable energy, and process optimization. Many facilities achieve carbon neutrality through these approaches.

Renewable Energy Integration

Solar Power Systems Green rubber production facilities increasingly use solar panels to generate clean electricity. Solar systems can provide 20-80% of facility power needs depending on location and system size.

Wind Energy Utilization Large manufacturing facilities use wind turbines to generate renewable electricity. Wind power provides consistent, clean energy for rubber processing operations.

Biomass Energy Systems Green rubber production technologies use biomass boilers and gasification systems to generate process heat and electricity. Agricultural waste and wood chips provide sustainable fuel sources.

Water Management Technologies

Rainwater Harvesting Green production facilities collect and use rainwater for non-potable applications. Rainwater harvesting reduces municipal water consumption and provides free water resources.

Greywater Recycling Advanced treatment systems recycle facility greywater for cooling towers, equipment cleaning, and other applications. Greywater recycling reduces fresh water consumption significantly.

Zero Liquid Discharge (ZLD) The most advanced green rubber production technologies achieve zero liquid discharge through comprehensive water treatment and recycling. ZLD systems eliminate wastewater discharge completely.

Recycling in Rubber Processing for Circular Economy

Recycling in rubber processing creates circular economy benefits by converting waste materials into valuable resources. Advanced recycling technologies transform used rubber products and manufacturing waste into raw materials for new production.

Modern recycling in rubber processing addresses the growing problem of rubber waste while creating economic value. These systems support sustainable manufacturing by providing alternative raw material sources.

Rubber Waste Processing Technologies

Mechanical Recycling Systems Mechanical recycling in rubber processing uses shredding, grinding, and separation technologies to break down used rubber products. These systems create rubber crumb and powder for reuse in new products.

Mechanical recycling can process various rubber waste types including tires, industrial products, and manufacturing scrap. The resulting materials maintain good properties for many applications.

Chemical Recycling Methods Advanced chemical recycling technologies break down rubber polymers into basic chemical components. These processes create raw materials identical to virgin materials for high-quality applications.

Devulcanization Technologies Devulcanization processes reverse the vulcanization process to create reusable rubber compounds. These technologies enable high-quality recycling that maintains material properties.

Tire Recycling Applications

Tire-Derived Fuel (TDF) Recycling in rubber processing converts waste tires into fuel for cement kilns and power plants. TDF provides clean-burning fuel while eliminating tire waste.

Rubber Mulch Production Ground tire rubber creates landscaping mulch and playground surfaces. This recycling application provides safe, durable surfaces while utilizing waste materials.

Road Construction Materials Recycled tire rubber improves asphalt performance in road construction. Rubberized asphalt lasts longer and provides better performance than conventional materials.

Manufacturing Waste Recovery

Process Scrap Recycling Recycling in rubber processing captures and reuses manufacturing scrap materials. Internal recycling systems process trim waste, off-specification products, and process waste.

Cross-Contamination Prevention Advanced separation technologies ensure recycled materials meet quality standards. Contamination control systems maintain material properties in recycled products.

Quality Control Systems Rigorous testing ensures recycled materials meet performance requirements. Quality control systems verify that recycled content maintains product specifications.

Sustainable Supply Chain Management

Sustainable supply chain management extends environmental responsibility beyond manufacturing to include suppliers, logistics, and end-of-life management. This comprehensive approach creates truly sustainable rubber production systems.

Effective sustainable supply chain management requires collaboration across multiple organizations and careful coordination of environmental initiatives. These efforts multiply the environmental benefits of sustainable manufacturing.

Supplier Sustainability Programs

Environmental Certification Requirements Sustainable supply chains require suppliers to meet environmental standards and certifications. ISO 14001 and other certifications ensure suppliers maintain environmental management systems.

Carbon Footprint Reporting Supply chain partners report their carbon emissions to enable comprehensive footprint calculations. This transparency enables targeted reduction efforts across the supply chain.

Sustainable Material Sourcing Responsible sourcing programs ensure raw materials come from sustainable sources. These programs address deforestation, labor practices, and environmental protection.

Green Logistics Solutions

Transportation Optimization Sustainable supply chains optimize transportation routes and methods to minimize emissions. Route optimization software and modal shift strategies reduce logistics environmental impact.

Packaging Reduction Sustainable packaging programs minimize material usage while maintaining product protection. Reusable containers and optimized packaging designs reduce waste significantly.

Local Sourcing Strategies Sourcing materials locally reduces transportation emissions and supports local economies. Regional supply networks create more resilient and sustainable supply chains.

End-of-Life Management

Product Take-Back Programs Sustainable manufacturers implement take-back programs to recover products at end-of-life. These programs enable recycling and proper disposal of rubber products.

Design for Recyclability Products designed for easy recycling facilitate end-of-life recovery. Design considerations include material selection, joining methods, and component identification.

Extended Producer Responsibility Manufacturers increasingly accept responsibility for products throughout their lifecycle. Extended producer responsibility programs fund collection and recycling infrastructure.

Economic Benefits of Sustainable Manufacturing

Sustainable manufacturing delivers significant economic benefits alongside environmental improvements. These financial advantages make sustainability initiatives attractive business investments that improve profitability while protecting the environment.

Understanding the economic benefits helps justify investments in sustainable technologies and motivates continued improvement efforts. Most sustainable manufacturing initiatives provide positive returns on investment.

Cost Reduction Opportunities

Energy Cost Savings Sustainable manufacturing significantly reduces energy costs through efficiency improvements and renewable energy. Energy savings often provide 15-40% cost reductions compared to traditional operations.

Material Cost Optimization Waste reduction and recycling programs reduce raw material costs. Some facilities achieve 10-25% material cost savings through improved efficiency and recycling.

Water Cost Reductions Water conservation and recycling systems reduce utility costs and wastewater treatment expenses. Water cost savings can be substantial in areas with high water costs.

Waste Disposal Cost Elimination Recycling and waste reduction programs eliminate disposal costs while creating revenue from recovered materials. Some facilities eliminate waste disposal costs entirely.

Revenue Generation Opportunities

Carbon Credit Sales Facilities that reduce greenhouse gas emissions can sell carbon credits in voluntary markets. Carbon credit revenues provide additional income streams for sustainable manufacturers.

Recycled Material Sales Manufacturing facilities can sell recovered materials and byproducts to other industries. Waste-to-revenue programs convert disposal costs into profit centers.

Green Product Premiums Sustainable products often command premium prices in the marketplace. Environmentally conscious consumers pay more for products with verified sustainability credentials.

Risk Management Benefits

Regulatory Compliance Proactive sustainability programs ensure compliance with current and future environmental regulations. Early adoption of sustainable practices reduces regulatory risks.

Supply Chain Resilience Sustainable supply chains demonstrate greater resilience to disruptions. Diversified sourcing and local suppliers reduce supply chain risks.

Reputation Protection Strong sustainability programs protect brand reputation and customer relationships. Environmental leadership creates competitive advantages in many markets.

Implementation Strategies for Sustainable Manufacturing

Successful implementation of sustainable manufacturing requires systematic approaches that address technology, operations, and organizational change. Well-planned implementation strategies ensure successful adoption of sustainable practices.

Effective implementation strategies consider technical requirements, financial constraints, and organizational capabilities. Phased approaches often work better than attempting comprehensive changes simultaneously.

Assessment and Planning Phase

Sustainability Audit Comprehensive audits identify current environmental impacts and improvement opportunities. Professional audits provide baseline measurements and prioritized improvement recommendations.

Goal Setting and Metrics Clear sustainability goals and measurement systems guide improvement efforts. SMART goals (Specific, Measurable, Achievable, Relevant, Time-bound) provide effective frameworks.

Investment Planning Financial planning considers implementation costs, payback periods, and funding sources. Investment planning helps prioritize projects and manage cash flow impacts.

Technology Selection and Integration

Technology Assessment Careful evaluation of available technologies ensures selection of appropriate solutions. Technology assessments consider performance, costs, and integration requirements.

Pilot Programs Small-scale pilot programs test new technologies before full implementation. Pilots reduce risks and provide implementation experience before major investments.

Phased Implementation Gradual implementation spreads costs over time and allows learning from early phases. Phased approaches reduce risks and enable course corrections.

Training and Change Management

Employee Training Programs Comprehensive training ensures employees understand and support sustainability initiatives. Training programs cover technical skills and environmental awareness.

Leadership Commitment Strong leadership support ensures successful sustainability program implementation. Leadership commitment provides resources and organizational support.

Culture Change Initiatives Sustainability requires cultural changes that embed environmental thinking into daily operations. Culture change programs create lasting organizational transformation.

Future Trends in Sustainable Rubber Manufacturing

The future of sustainable rubber manufacturing includes emerging technologies and evolving market demands. Understanding these trends helps manufacturers prepare for future requirements and opportunities.

Emerging trends in sustainable manufacturing will continue transforming the rubber industry. Early adoption of these trends creates competitive advantages and positions companies for future success.

Emerging Technologies

Artificial Intelligence for Optimization AI systems will optimize sustainable manufacturing operations automatically. Machine learning algorithms will identify efficiency opportunities and control systems in real-time.

Advanced Material Sciences New bio-based materials and recycling technologies will expand sustainable manufacturing options. Advanced materials will provide better performance with lower environmental impact.

Blockchain for Traceability Blockchain technology will provide transparent supply chain traceability for sustainable materials. This technology will verify sustainability claims and prevent greenwashing.

Regulatory Evolution

Stricter Environmental Standards Future regulations will require more stringent environmental performance. Manufacturers must prepare for carbon pricing, extended producer responsibility, and stricter emission limits.

Circular Economy Mandates Governments increasingly mandate circular economy practices including recycling requirements and waste reduction targets. These regulations will reshape manufacturing practices.

Carbon Neutrality Requirements Many jurisdictions are implementing carbon neutrality requirements for industrial operations. Manufacturers must plan for net-zero emissions requirements.

Market Developments

Consumer Demand for Sustainability Growing consumer environmental awareness drives demand for sustainable products. Manufacturers must meet these expectations to remain competitive.

Investor Focus on ESG Environmental, Social, and Governance (ESG) investing drives capital toward sustainable manufacturers. Companies with strong sustainability programs attract investment more easily.

Supply Chain Sustainability Requirements Large customers increasingly require sustainability certification from suppliers. Supply chain sustainability requirements will become standard business practices.

Conclusion

Sustainable rubber manufacturing represents the future of the industry, combining environmental responsibility with economic benefits. Through energy-efficient rubber machinery, eco-friendly rubber manufacturing processes, and comprehensive recycling in rubber processing, manufacturers can achieve both sustainability goals and business success.

The transition to sustainable rubber processing requires investment in new technologies and operational changes. However, the economic benefits including cost savings, revenue opportunities, and risk reduction justify these investments.

Green rubber production technologies continue evolving, offering new opportunities for environmental improvement and cost reduction. Manufacturers that embrace these technologies position themselves for long-term success in an increasingly environmentally conscious marketplace.

Recycling in rubber processing and circular economy approaches will become increasingly important as raw material costs rise and waste disposal becomes more expensive. These approaches create economic value while addressing environmental challenges.

The future belongs to manufacturers that successfully integrate sustainability into their core business strategies. Sustainable rubber processing provides the pathway to environmental leadership, cost reduction, and market differentiation in the global rubber industry.

Companies like Vikas Industries are leading this transformation by offering energy-efficient equipment and sustainable manufacturing solutions. The time to begin this transition is now, as the benefits of sustainable manufacturing compound over time and early adopters gain competitive advantages that become difficult for others to match.