Choosing the appropriate rubber processing equipment is essential for increasing productivity, cutting waste, and guaranteeing high-quality results. Making an informed choice may have a big influence on your company’s operations, whether you’re updating your current machinery or establishing a new rubber production facility. We’ll go over important considerations for rubber processing machine selection in this tutorial, along with tips for picking the ideal equipment for your requirements.

1. Recognize your needs for production

Consider your manufacturing requirements before investing in a rubber processing machine:

Production Volume: How much rubber must be processed per day?

Product Type: Do you make extruded parts, molded goods, or rubber sheets?

Material Compatibility: Verify that the machine is capable of handling various rubber varieties, including silicone, synthetic, and natural rubber.

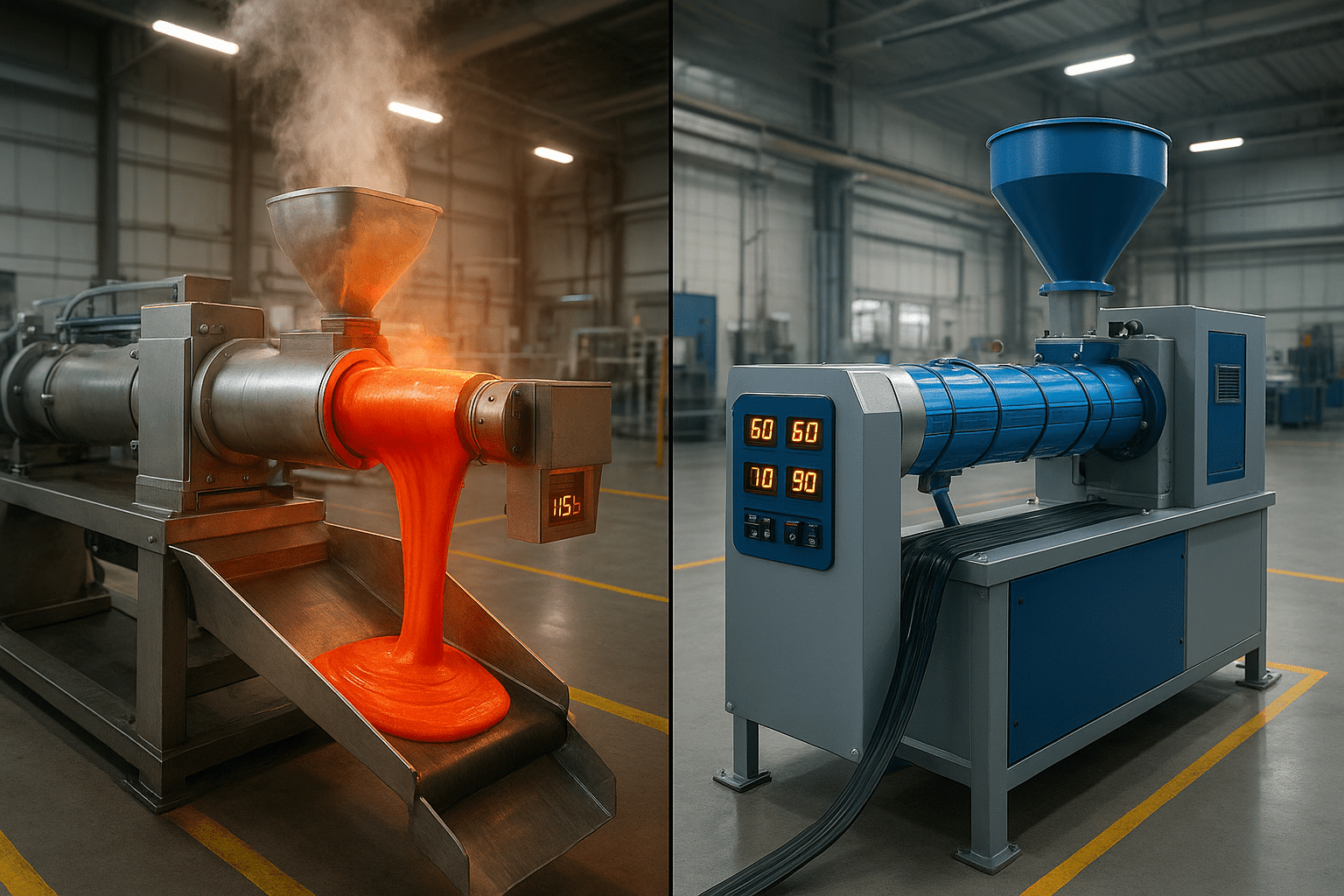

2. Rubber Processing Machine Types

Rubber processing equipment comes in a variety of forms, each with a distinct function:

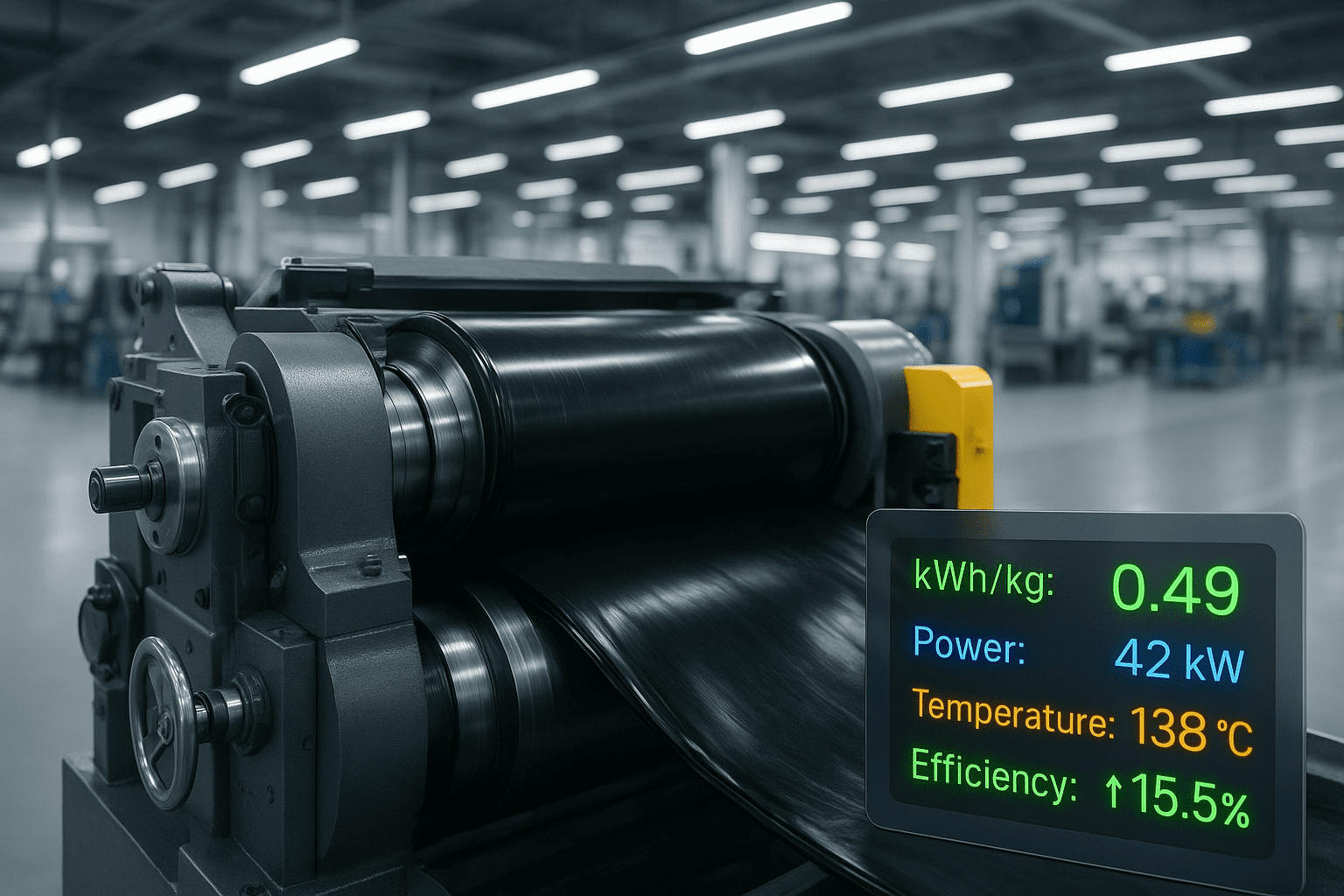

Rubber Mixing Mill: Perfect for combining additives with raw rubber.

Dispersion Kneader: A dispersion kneader is used to mix rubber compounds uniformly.

Compression Moulding Press: A compression molding press is a necessary tool for producing molded rubber goods.

Vacuum Moulding Press : A vacuum molding press removes air bubbles and guarantees excellent accuracy.

Rubber Extruder Machine: Continuous rubber profiles of constant quality are produced by a rubber extruder machine.

Rubber Bale Cutter: Raw rubber bales are cut into workable proportions with a rubber bale cutter.

3. Important Considerations

Take into account the following characteristics while choosing a rubber processing machine:

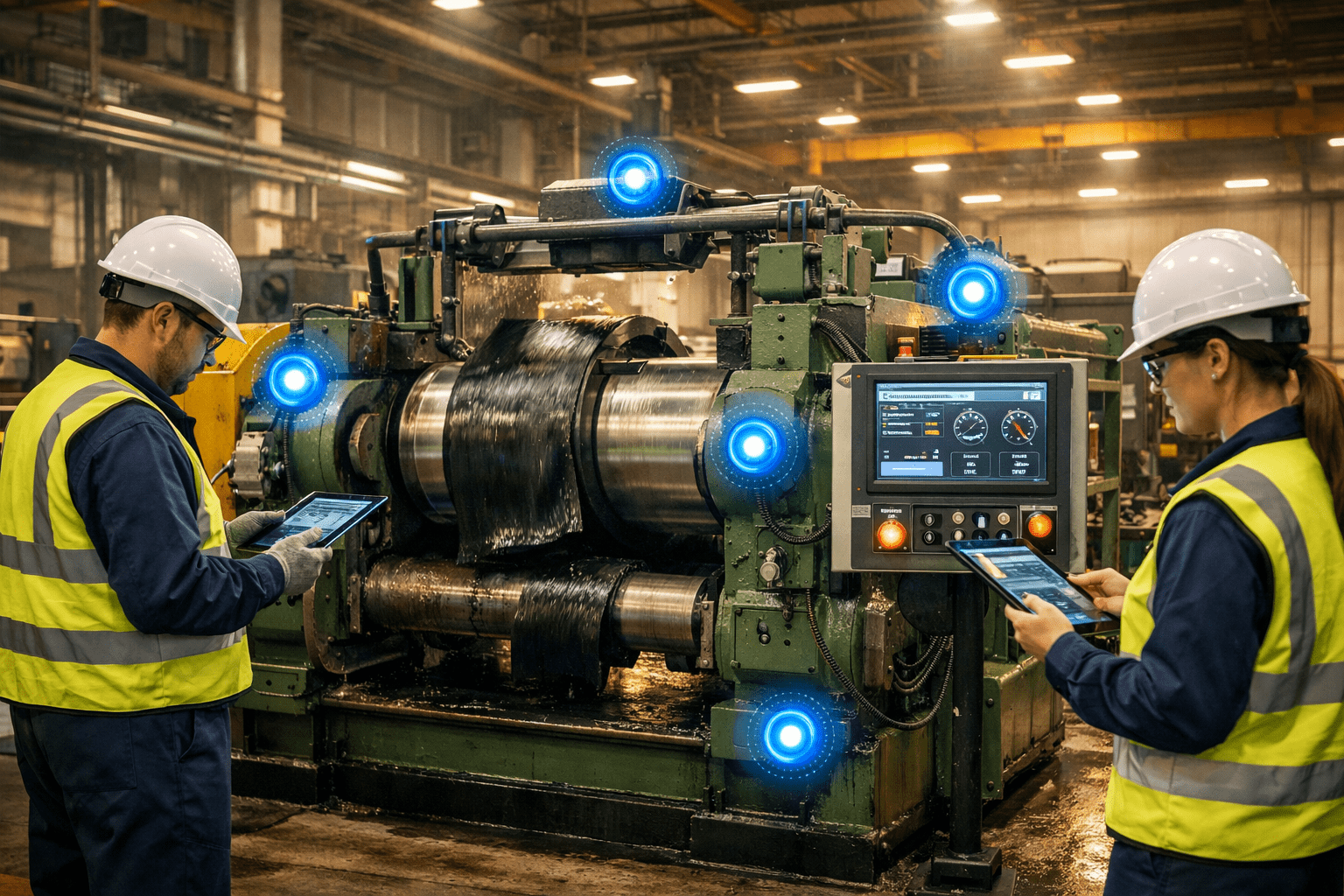

Automation Level: Fully automated equipment saves manual work and boosts productivity.

Energy Efficiency: To cut operating expenses, use equipment that uses less energy.

Durability & Build Quality: Longevity is improved by machines constructed from premium steel.

Ease of Maintenance: Select devices with little downtime and easily replaceable parts.

Safety Features: Look for controls that are easy to use, overload protection, and emergency stop devices.

4. Dependability of Manufacturers and Suppliers

Reliability and lifespan are guaranteed when you choose a top-notch machine from a respectable manufacturer. Think about:

Brand Reputation: Examine consumer reviews and testimonies.

Warranty & Support: Check for technical support, spare component availability, and post-purchase service.

Options for Customization: Certain manufacturers provide solutions that are specifically tailored to your company’s requirements.

5. Adherence to Industry Standards

Verify that the machine conforms with industry rules and safety specifications, including:

ISO Certification for Assurance of Quality

CE Marking to ensure safety compliance

Environmental laws to reduce emissions and waste

Conclusion

Choosing the right rubber processing machine is a strategic decision that affects productivity, product quality, and overall business success. By evaluating production requirements, machine types, key features, and supplier reliability, you can make an informed investment that ensures long-term profitability.

If you’re looking for high-quality rubber processing machinery, explore our range of solutions tailored to your needs. Contact us today for expert guidance on selecting the best machine for your business!