Hydraulic presses are strong devices with uses in a wide range of sectors, including electronics, aerospace, and automotive as well as metallurgy. Vacuum and compression operations are only two of the many procedures that these sturdy machines are invaluable for because they use the power of hydraulic fluid to generate enormous forces.

Understanding Hydraulic Presses

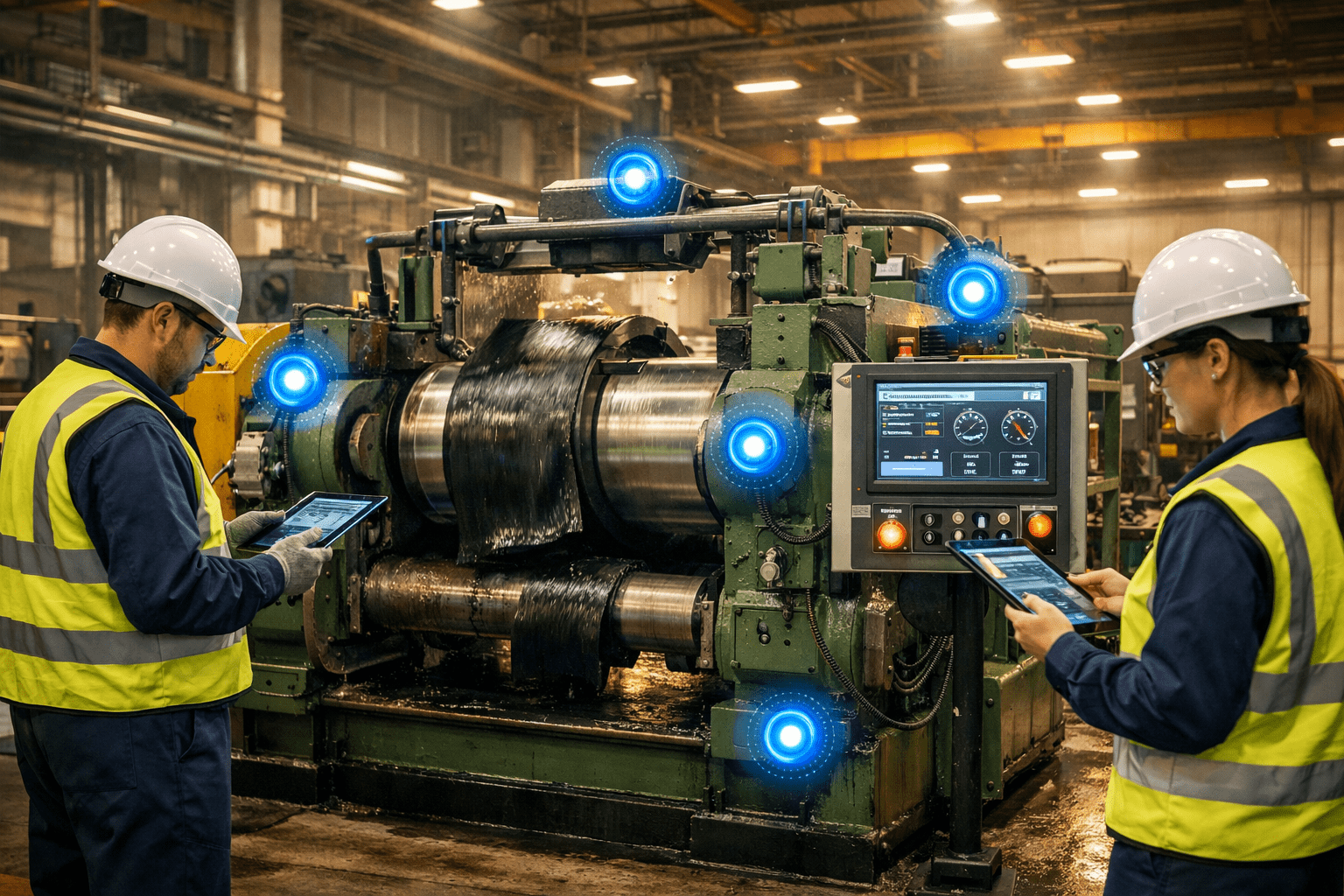

A hydraulic press has a robust structure, a hydraulic piston, and a ram responsible for exerting force. The ram moves and applies force to the workpiece when hydraulic fluid is pushed into the cylinder, creating pressure. Because the fluid pressure can be precisely adjusted to provide the desired amount of force, hydraulic presses are very versatile and can handle a wide range of materials and applications.

Hydraulic presses are widely used in vacuum and compression applications across various industries:

Vacuum Applications:

Vacuum Forming: This method involves covering a mold with a heated plastic sheet and using vacuum pressure to force the plastic to take on the shape of the mold. The force required to produce the vacuum and keep the plastic in place during the forming process is supplied by hydraulic presses.

Vacuum metallurgy: This process produces high-density, high-strength components by compacting and sintering metal powders in a vacuum. During the compaction stage, the required pressure is applied using hydraulic presses

Compression Applications:

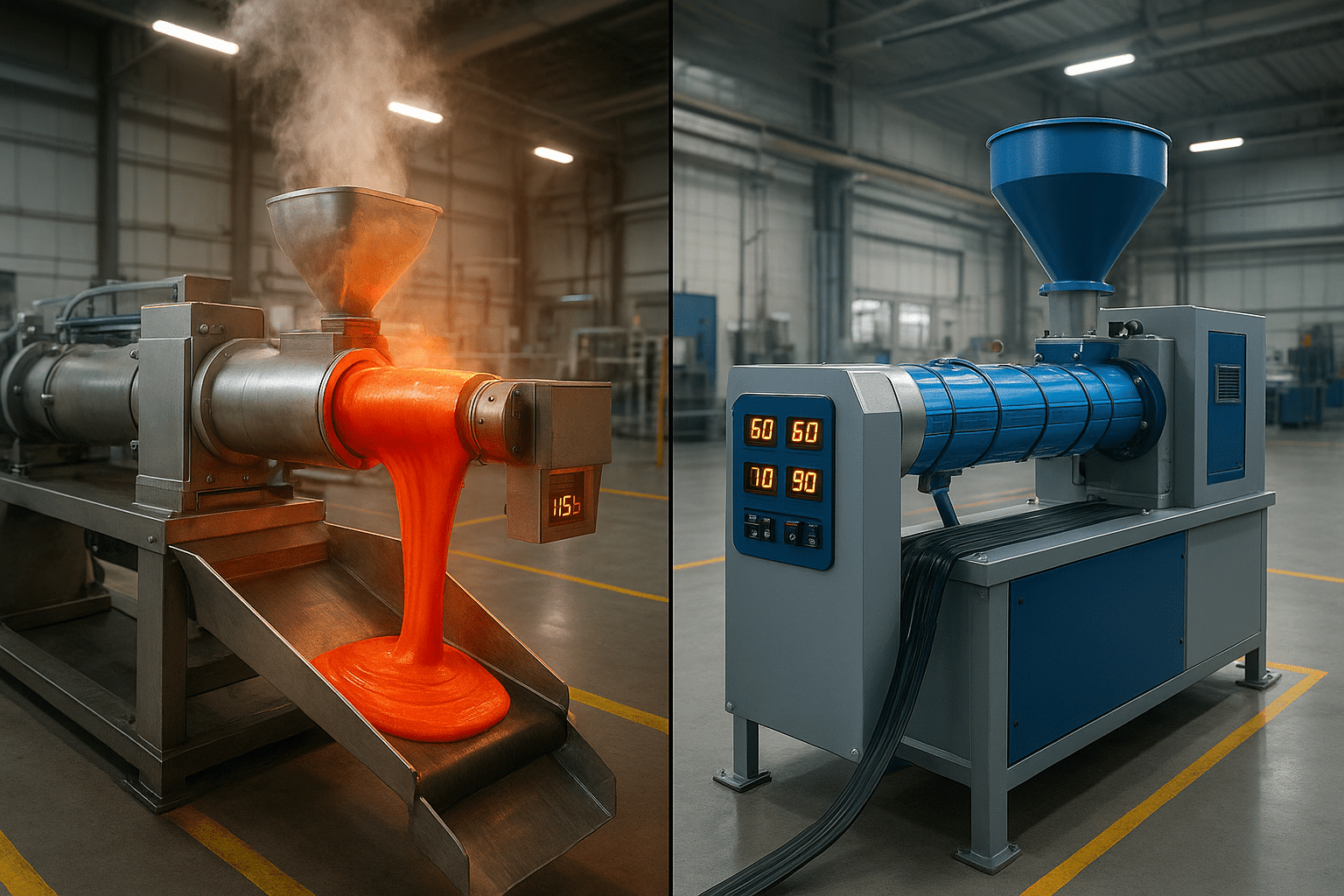

Compression Molding: As previously indicated, thermosetting polymers are shaped using compression molding presses by applying heat and pressure, which produces high-strength, dimensionally stable products.

Production of Laminates: Layers of material are crushed together under high pressure and heat in hydraulic presses to create laminates like fiberboard and plywood.

Powder Compaction: Metal powders are compacted into dense, nearly-net-shaped components in the powder metallurgy sector using hydraulic presses. These components are then sintered to acquire the required strength and characteristics.

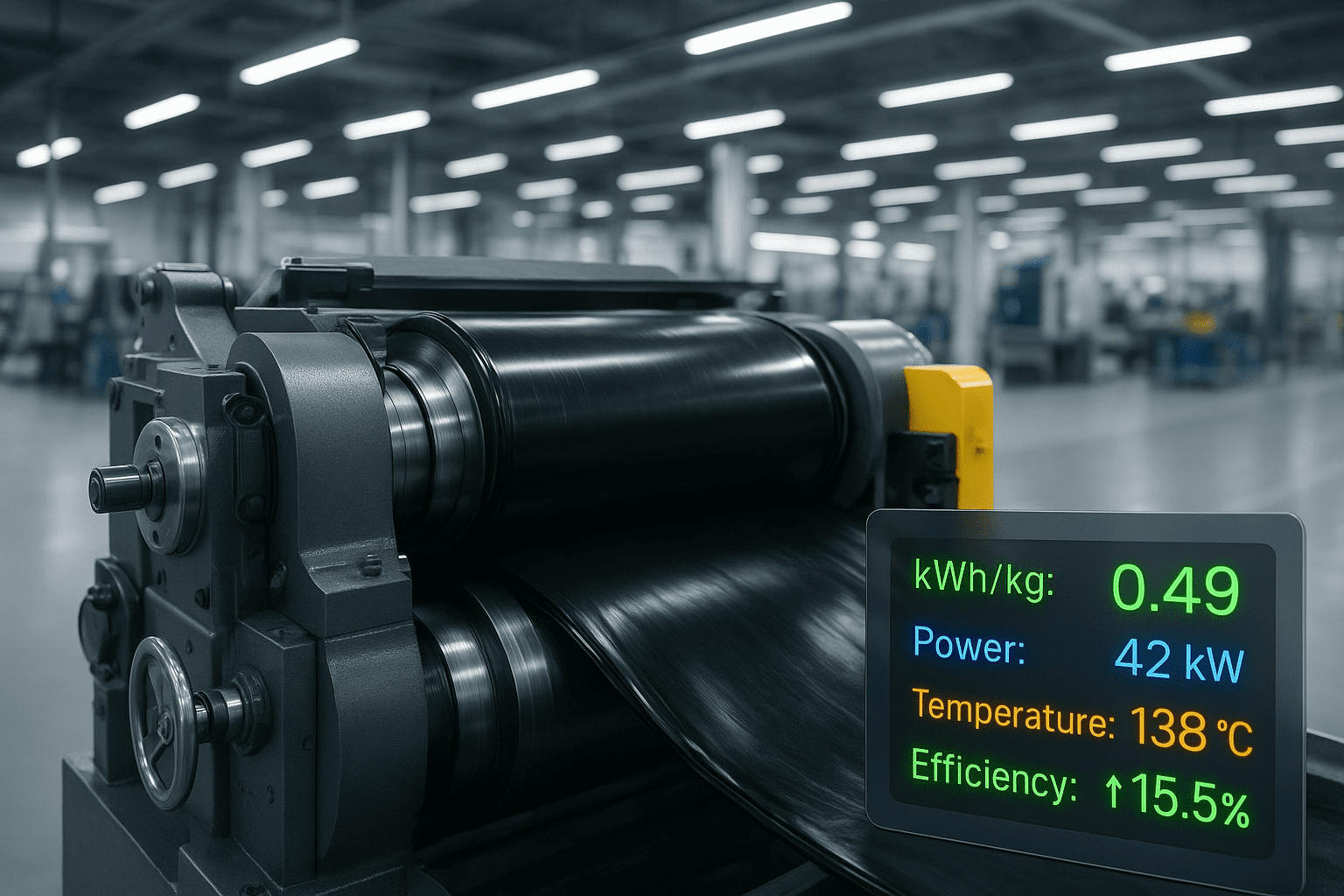

Stamping and Forming: When strong forces are needed to shape and distort metal workpieces, the metalworking industry frequently uses hydraulic presses for stamping, forming, and deep drawing processes.

Conclusion:

Strong and adaptable, hydraulic presses are essential pieces of equipment in many different sectors, especially for compression and vacuum applications. They are crucial for operations like metalworking, vacuum forming, compression molding, and powder compaction because of their exceptional controllability in producing enormous forces. Hydraulic presses will continue to be at the forefront of manufacturing technology as industries continue to change and seek more sophisticated methods. They provide the force and accuracy needed to mold materials into high-performing, innovative products.